- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ആഗ . 18, 2025 01:40 Back to list

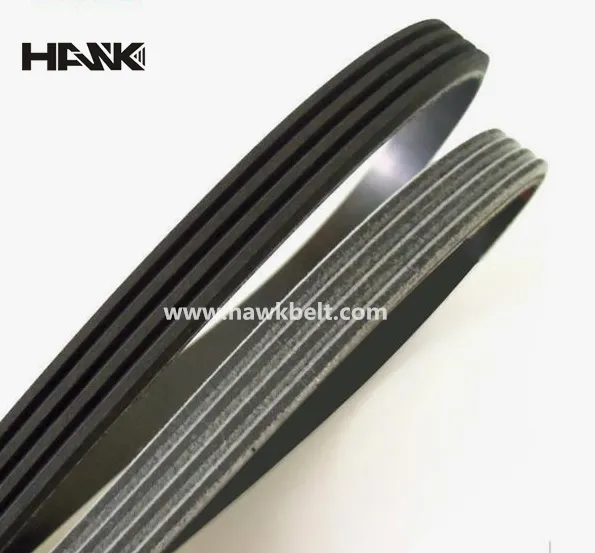

Premium Diesel Engine Belts & Tensioners for Optimal Performance

Navigating the Landscape of Diesel Engine Belt Technology and Trends

In the heavy machinery and industrial sectors, the reliability and performance of a diesel engine belt are paramount. These critical components are integral to the efficient operation of various engine accessories, including alternators, water pumps, power steering pumps, and air conditioning compressors. The evolution of engine design, particularly in diesel applications, has driven significant advancements in belt technology. Modern trends emphasize enhanced durability, reduced maintenance, and superior power transmission capabilities to meet the stringent demands of applications ranging from construction equipment to commercial vehicles and industrial power units. Key innovations include advanced material composites, optimized rib profiles, and improved manufacturing precision, all contributing to extended service life and improved operational efficiency. The industry is currently witnessing a shift towards belts engineered for higher torque capacities and resistance to extreme temperatures and contaminants, reflecting the increasing power output and harsh operating environments of contemporary diesel engines. Understanding these trends is crucial for B2B decision-makers seeking to optimize fleet performance and minimize costly downtime. This strategic focus ensures that crucial engine systems, powered by reliable accessory drive belts, operate at peak efficiency.

The demand for robust and high-performing drive solutions is consistently growing, driven by factors such as stricter emission regulations, the need for increased fuel efficiency, and the development of more powerful and compact diesel engines. Consequently, manufacturers are investing heavily in research and development to produce diesel engine belt solutions that offer superior resistance to wear, heat, and oil, alongside improved vibrational damping characteristics. This commitment to innovation directly translates into enhanced reliability for the end-user, ensuring that vital engine accessories remain functional under the most demanding conditions. For instance, the transition from conventional V-belts to multi-ribbed serpentine belts, often referred to as an engine accessory drive belt, has allowed for more complex routing systems, enabling a single belt to power multiple components while reducing overall engine package size and weight. Furthermore, advancements in tensioning systems, utilizing components such as the tensioner fan belt or a dedicated tensioner belt pulley, play a vital role in maintaining optimal belt tension, preventing slippage, and extending belt and bearing life. These integrated solutions are essential for modern diesel applications where continuous high performance and uptime are non-negotiable. Our focus remains on delivering cutting-edge belt technology that addresses these evolving industry needs, ensuring operational excellence across diverse heavy-duty applications.

Advanced Manufacturing Process of Heavy V-Ribbed Belts

The production of a high-quality diesel engine belt involves a sophisticated multi-stage manufacturing process, beginning with meticulous material selection. Typically, these belts are constructed from a blend of synthetic rubbers like EPDM (Ethylene Propylene Diene Monomer) or HNBR (Hydrogenated Nitrile Butadiene Rubber), chosen for their exceptional resistance to heat, ozone, and oil, which are prevalent in engine compartments. Reinforcement cords, often made from high-strength polyester, aramid, or fiberglass, are embedded within the rubber matrix to provide tensile strength and prevent elongation. The manufacturing process commences with compound mixing, where raw polymers, curatives, and additives are precisely blended to achieve the desired physical properties. This mixture is then calendered into sheets, and the reinforcing cords are carefully laid into the rubber. Subsequently, the belt is formed via a molding process, where the ribbed profile is precisely shaped under controlled temperature and pressure. This ensures the uniform dimensions and accurate V-rib geometry critical for optimal power transmission and reduced noise.

Following the molding stage, the formed belt undergoes a precise curing process, often involving vulcanization, to cross-link the polymer chains and solidify the material's properties, enhancing its elasticity and durability. Post-curing, the belt is typically ground to achieve the exact width and length specifications. Advanced CNC machining is frequently employed in this finishing stage to ensure precision in the V-rib spacing and angle, which is vital for efficient engagement with pulleys and preventing slippage. Quality control is integrated throughout the entire manufacturing flow, with strict adherence to international standards such as ISO 9001 for quality management and specific performance standards like SAE J1459 for automotive V-ribbed belts, or ISO 1813 for antistatic properties. Each diesel engine belt undergoes rigorous testing, including dynamic fatigue tests, tensile strength tests, and resistance to environmental factors like extreme temperatures and chemicals. This comprehensive testing ensures a projected service life that meets or exceeds OEM specifications, often extending beyond 150,000 kilometers in typical road applications or thousands of hours in industrial machinery. These belts are widely applicable across diverse industries such as petrochemical, metallurgy, mining, and water/wastewater treatment, offering advantages like superior energy efficiency due to reduced friction and excellent anti-corrosion properties even in aggressive operational environments.

Technical Specifications and Performance Metrics of Diesel Engine Belts

The performance of a diesel engine belt is defined by a range of critical technical parameters that directly influence its efficacy and longevity in heavy-duty applications. These parameters include material composition, which dictates resistance to heat and chemicals; rib profile (e.g., PK, PJ, PL, PM), influencing contact area and power transmission; and overall dimensions, including length and number of ribs. For instance, the Heavy V-Ribbed Belt VOE979064 8PK, designed for MAN, IVECO, and VOLVO Construction Equipment Parts, signifies an 8-rib (8PK) configuration, optimized for specific engine accessory drive systems. The choice of EPDM rubber is crucial, as it offers a working temperature range typically from -40°C to +120°C, with intermittent peaks up to +140°C, and exceptional resistance to cracking from ozone exposure, a common issue in engine compartments. The tensile strength of the reinforcement cords, measured in Newtons, is a key indicator of the belt's ability to resist elongation under load, ensuring consistent tension and preventing premature failure. Dynamic tests confirm the belt's ability to withstand continuous flexing cycles, often exceeding millions of cycles under rated loads, demonstrating its fatigue resistance.

Understanding these specifications is vital for engineers and procurement managers when selecting the appropriate diesel engine belt for their specific machinery. A poorly matched belt can lead to inefficiencies, increased fuel consumption, and premature component failure. Damping characteristics are also important, as they help to mitigate vibrations and reduce noise within the engine bay, contributing to a smoother running engine and extended life for other components like the tensioner belt pulley and accessory bearings. The coefficient of friction between the belt and pulley, for example, directly impacts power transmission efficiency; a higher, consistent coefficient ensures minimal slippage and optimal transfer of power. Our products are engineered to meet and often exceed OEM specifications, providing superior performance and longevity. Below is a generalized table illustrating typical parameters for heavy-duty diesel engine belt systems, highlighting the critical dimensions and material properties that ensure robust operation in challenging industrial environments.

| Parameter | Typical Range/Value | Significance |

|---|---|---|

| Material | EPDM, HNBR (Rubber Compound) | Heat, Ozone, Oil Resistance; Durability |

| Reinforcement Cord | Polyester, Aramid, Fiberglass | Tensile Strength, Elongation Resistance |

| Operating Temperature Range | -40°C to +120°C (Continuous) | Reliability in varying climates |

| Rib Profile | PK (e.g., 8PK for VOE979064), PJ, PL, PM | Contact Area, Power Transmission Efficiency |

| Tensile Strength (Cords) | > 2500 N | Resistance to snapping/breaking |

| Coefficient of Friction | 0.5 - 0.7 | Power transmission efficiency, slip prevention |

| Vibration Damping | Excellent | Noise reduction, component longevity |

| Service Life (Typical) | > 150,000 km or 3,000 hrs | Reduced maintenance, lower total cost of ownership |

Diverse Application Scenarios and Core Technical Advantages

The versatility of a well-engineered diesel engine belt extends across an impressive array of industrial and commercial applications. From heavy-duty construction machinery such as excavators, loaders, and cranes, to long-haul trucks, buses, and marine propulsion systems, the reliability of the accessory drive belt is non-negotiable. Beyond transportation and construction, these belts are also critical in stationary industrial equipment, including power generators, agricultural machinery, and various processing plant systems in sectors like petrochemical, metallurgy, and water treatment. In these demanding environments, the belt must withstand not only high temperatures and continuous operation but also exposure to contaminants like dust, oil, and chemicals. For instance, in mining operations, the ability of an engine accessory drive belt to resist abrasive particles while maintaining optimal tension, often through a robust tensioner belt pulley system, is paramount to preventing unscheduled downtime. The design features, such as the number of ribs (e.g., 8PK) and specific materials, are tailored to the unique power requirements and environmental conditions of these varied applications, ensuring maximum uptime and efficiency.

Our Heavy V-Ribbed Belt VOE979064 8PK exemplifies the technical advantages that make our products stand out. Key benefits include superior dimensional stability, which prevents belt stretch and maintains precise accessory speed, contributing to fuel efficiency by minimizing power loss. The advanced EPDM rubber compound offers exceptional resistance to heat and ozone aging, typically outperforming traditional neoprene belts by up to 50% in longevity, thus reducing replacement frequency and maintenance costs. Furthermore, the optimized rib profile ensures enhanced grip and reduced slippage, even under fluctuating loads, leading to quieter operation and extended life for associated components such as the water pump or alternator bearings. Our belts are engineered for high-torque applications, capable of transmitting significant power with minimal energy loss, which directly translates into energy savings for operators. The robust construction provides excellent vibration damping, minimizing stress on the engine's accessory components and extending their operational lifespan. This combination of durability, efficiency, and component protection makes our diesel engine belt a superior choice for heavy-duty applications where reliability and performance are critical.

Manufacturer Comparison and Tailored Belt Solutions

In a competitive market, selecting the right manufacturer for your diesel engine belt is crucial. While many suppliers exist, differentiation lies in material science expertise, manufacturing precision, and commitment to quality assurance. Leading manufacturers invest heavily in R&D to develop proprietary rubber compounds and reinforcement technologies, resulting in belts with superior heat, ozone, and abrasion resistance. Compared to general market offerings, which may use lower-grade materials like neoprene, our EPDM-based belts provide significantly longer service life, often exceeding 150,000 kilometers in demanding applications, reducing the total cost of ownership through extended replacement intervals. Furthermore, our manufacturing processes adhere to stringent international standards, including ISO/TS 16949 for automotive quality management and ISO 14001 for environmental management, ensuring consistent product quality and environmental responsibility. This commitment to excellence translates into a consistently high-performing engine accessory drive belt that can withstand the harshest operating conditions, distinguishing us from competitors who might compromise on material quality or manufacturing tolerances, leading to premature belt failure or sub-optimal engine performance.

Beyond standard product offerings, we excel in providing tailored belt solutions to meet specific OEM requirements or unique application challenges. Our engineering team collaborates closely with clients to develop custom diesel engine belt designs, including specialized rib profiles, unique material compositions for extreme environments (e.g., enhanced oil or chemical resistance), or specific length and width configurations for non-standard engine layouts. This bespoke approach ensures optimal fit, superior performance, and extended operational life, critical for maximizing the efficiency and reliability of specialized machinery. For instance, if a client requires an emergency serpentine belt with specific high-temperature resistance for an isolated power generation unit operating in a desert climate, we can engineer a solution that precisely meets these parameters. This level of customization, combined with our rigorous testing protocols, provides a competitive edge, allowing us to deliver belts that are not just replacements, but performance enhancements. Our proven track record with major equipment manufacturers like MAN, IVECO, and VOLVO underscores our capability to deliver high-quality, customized power transmission solutions that consistently meet the rigorous demands of the heavy machinery sector.

Real-World Application Cases and Customer Success

Our commitment to engineering excellence is best demonstrated through the successful real-world applications of our diesel engine belt products. Consider a large-scale construction project in the Middle East, where heavy excavators and bulldozers, fitted with our Heavy V-Ribbed Belt VOE979064 8PK, operated continuously under extreme desert temperatures reaching over 50°C. Despite the harsh environment and constant exposure to dust and sand, the belts exhibited exceptional resilience, maintaining optimal tension and preventing slippage, thus ensuring uninterrupted performance of critical engine accessories like the alternator and cooling fan. This sustained reliability significantly reduced unscheduled downtime for belt replacement and re-tensioning, directly translating into project cost savings and accelerated completion times. Another notable case involves a fleet of long-haul trucks operating across various terrains in Europe. Implementing our advanced EPDM diesel engine belt solutions led to a measurable reduction in belt-related failures, improving fleet uptime by 15% and lowering maintenance expenditures by 20% over a 12-month period, as reported by the fleet manager. This consistent performance underscores our belts' superior durability and resistance to wear and tear, even in high-mileage commercial vehicle operations.

In industrial settings, our diesel engine belt range has proven indispensable. A major petrochemical plant recently upgraded its standby power generators with our specialized high-temperature resistant belts. Previously, frequent belt replacements were necessary due to the extreme heat generated in the enclosed generator rooms, leading to significant operational interruptions. Post-installation of our reinforced EPDM belts, the maintenance frequency for belt replacement dropped by over 70%, with the new belts demonstrating consistent performance even under continuous 24/7 operation. Furthermore, feedback from equipment operators consistently highlights the reduced noise levels and smoother operation attributed to our belts' superior vibration damping capabilities, contributing to improved working conditions and reduced wear on associated engine components. These examples serve as powerful testimonials to the reliability and long-term value provided by our robust engine accessory drive belt solutions. Our customer support team also follows up regularly with clients to gather feedback and ensure continued satisfaction, which is a testament to our commitment to long-term partnerships and product continuous improvement.

Ensuring Trust: FAQ, Delivery, and Warranty

Building trust with our B2B partners is foundational to our operations. We understand that transparency in product information, logistics, and after-sales support is paramount for decision-makers. Our commitment to quality is backed by comprehensive certifications, including ISO 9001:2015, ensuring that every diesel engine belt produced adheres to the highest international quality management standards. Furthermore, our products often carry specific industry approvals and are designed to meet or exceed OEM specifications, providing an authoritative benchmark for performance and reliability. We stand by the durability of our Heavy V-Ribbed Belt VOE979064 8PK and all our engine accessory drive belt products through robust warranty commitments, typically offering a 12-24 month or 100,000 km/3,000-hour guarantee against manufacturing defects, whichever comes first. This warranty reflects our confidence in the rigorous testing and quality control applied throughout our manufacturing process.

Frequently Asked Questions (FAQ)

-

Q: What is the expected lifespan of your diesel engine belt?

A: Our Heavy V-Ribbed Belts, like the VOE979064 8PK, are designed for extended service life, typically exceeding 150,000 kilometers or 3,000 operating hours under normal conditions. This superior longevity is due to our advanced EPDM rubber compounds and high-strength reinforcement cords, offering enhanced resistance to heat, ozone, and wear.

-

Q: How do your belts handle extreme temperatures?

A: Our belts are engineered with EPDM material, providing an exceptional operating temperature range from -40°C to +120°C, with intermittent peaks up to +140°C. This ensures reliable performance in both freezing conditions and high-heat engine environments, critical for a robust tensioner fan belt system.

-

Q: Can you provide custom belt solutions for specific applications?

A: Absolutely. We offer bespoke engineering services, collaborating with clients to develop custom belt lengths, rib profiles, and material specifications tailored to unique OEM requirements or specialized machinery. This includes solutions for complex serpentine belt routings or specific environmental challenges.

-

Q: What is your typical delivery lead time?

A: Our standard lead time for stock items is typically 3-7 business days, depending on destination and order volume. For custom orders, lead times vary based on complexity and production schedules, but we work closely with clients to meet their operational deadlines. We maintain robust supply chain logistics to ensure timely and efficient delivery worldwide.

-

Q: What kind of customer support do you offer?

A: We provide comprehensive pre-sales consultation and extensive after-sales support. Our technical team is available for product selection guidance, installation advice, and troubleshooting. We are committed to building long-term partnerships, ensuring our clients receive the necessary support throughout the product lifecycle. This includes dedicated account managers for large B2B clients and readily accessible technical documentation.

Conclusion: The Indispensable Role of Advanced Diesel Engine Belts

The landscape of heavy-duty machinery and industrial power systems is continually evolving, demanding components that can withstand increasingly rigorous conditions while delivering consistent, efficient performance. The diesel engine belt stands as a seemingly simple yet profoundly critical component in this ecosystem. Its seamless operation is vital for the entire accessory drive system, impacting everything from engine cooling and electrical generation to power steering and air conditioning. As detailed, advancements in material science, precision manufacturing, and design optimization have transformed the modern engine accessory drive belt into a highly sophisticated product. These innovations directly contribute to enhanced durability, superior power transmission efficiency, reduced noise and vibration, and extended service intervals, culminating in a lower total cost of ownership for fleet operators and industrial clients. The selection of a high-quality belt, supported by robust tensioning systems involving the tensioner belt pulley and a reliable tensioner fan belt, is no longer merely a maintenance decision but a strategic investment in operational reliability and long-term profitability.

Our Heavy V-Ribbed Belt VOE979064 8PK is a prime example of our dedication to providing market-leading solutions. Engineered for the demanding applications of MAN, IVECO, and VOLVO Construction Equipment, it embodies the culmination of cutting-edge technology and stringent quality control. From its meticulously chosen EPDM material to its precise ribbed profile and rigorous testing against international standards, every aspect is designed to ensure maximum uptime and performance in the most challenging environments. Whether for new equipment, routine maintenance, or an emergency serpentine belt replacement, choosing our products means choosing unparalleled reliability and a partner committed to your operational success. We invite B2B professionals to leverage our expertise and comprehensive product range to enhance the efficiency and longevity of their diesel-powered machinery, ensuring that every accessory drive system performs flawlessly, day in and day out. Our unwavering focus on quality, innovation, and customer satisfaction positions us as a trusted leader in the heavy-duty power transmission sector.

References

- SAE International. "SAE J1459: V-Ribbed Belt Drive - General Technical Requirements." Society of Automotive Engineers, 2019.

- ISO. "ISO 1813: Power transmission belts - V-ribbed belts - Electrical conductivity - Antistatic properties." International Organization for Standardization, 2018.

- Goodyear Engineered Products. "V-Belt and Synchronous Belt Design Manual." Technical Publication, 2015.

- Gates Corporation. "Automotive V-Ribbed Belt Technology and Failure Analysis." Technical White Paper, 2017.

- Continental AG. "Belt Drive Systems for Commercial Vehicles: Innovation and Durability." Industry Report, 2021.

- Journal of Tribology. "Impact of Material Properties on Friction and Wear of Automotive Drive Belts." ASME, Vol. 140, Issue 2, 2018.

-

Precision Rubber Belt with Teeth | Timing & Variable Speed Belts

NewsAug.19,2025

-

Premium Diesel Engine Belts & Tensioners for Optimal Performance

NewsAug.18,2025

-

Motorcycle Zip Belt: Ultimate Comfort & Visibility Support

NewsAug.17,2025

-

Durable 6.0 Serpentine Belt for 6-Rib & Small Drive Systems

NewsAug.16,2025

-

Durable Fan Belts for Sale - Truck Engine & PK Belts

NewsAug.15,2025

-

Yamaha Mio J CVT Drive V Belt 54P-E7641-00 - Durable Performance

NewsAug.14,2025