- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ഒക്ട് . 12, 2024 11:21 Back to list

neoprene timing belt

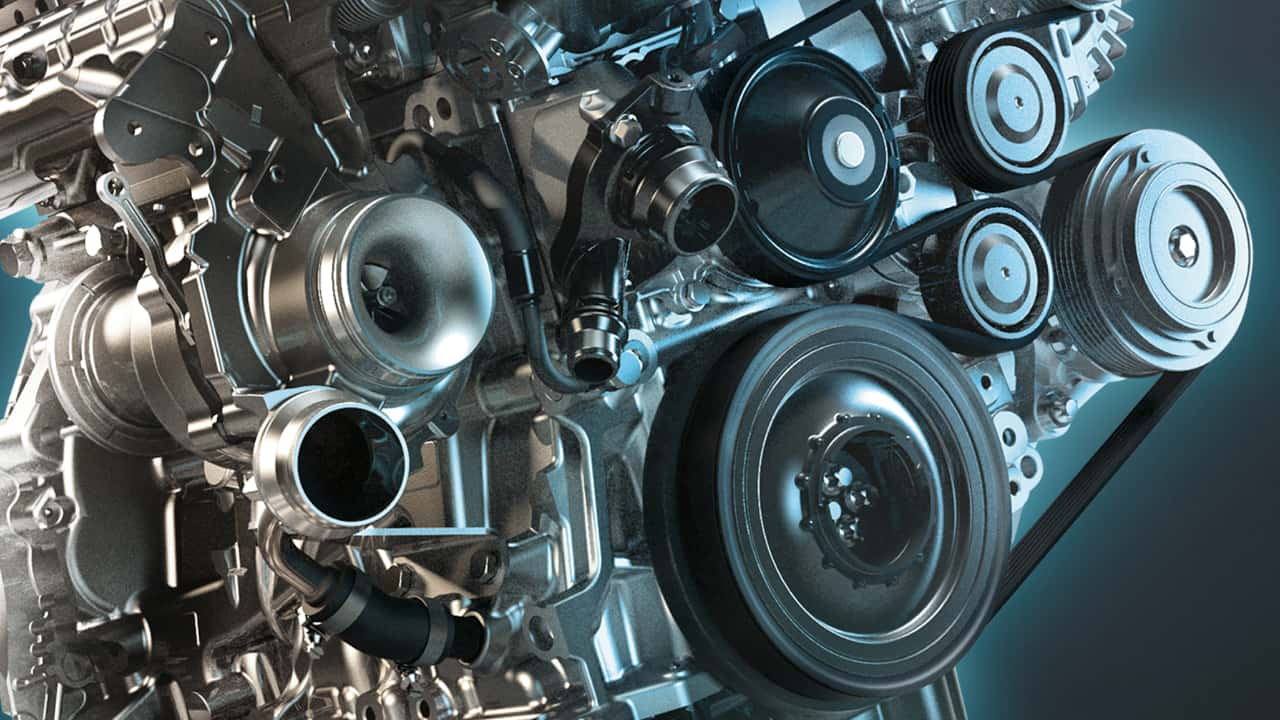

The Benefits of Neoprene Timing Belts An Essential Component in Mechanical Systems

Timing belts play a crucial role in various mechanical systems, providing synchronization between components such as gears, pulleys, and crankshafts. Among the different materials available for timing belts, neoprene stands out due to its exceptional characteristics and wide range of applications. In this article, we'll delve into the key features of neoprene timing belts, their advantages, ideal uses, and tips for maintenance.

What is Neoprene?

Neoprene, also known as polychloroprene, is a synthetic rubber that was first developed in the 1930s. It is renowned for its impressive waterproof properties, resilience, and resistance to oils and chemicals. These attributes make neoprene an ideal choice for a variety of mechanical applications, including the production of timing belts. The inherent flexibility and durability of neoprene allow timing belts made from this material to perform reliably, even under varying conditions.

Advantages of Neoprene Timing Belts

1. Durability One of the standout features of neoprene timing belts is their remarkable strength and longevity. Neoprene can withstand wear and tear more effectively than many other materials, which is critical in high-stress applications. This durability translates to extended maintenance intervals and reduced costs associated with replacements.

2. Temperature Resistance Neoprene exhibits excellent thermal stability, functioning effectively in both high and low-temperature environments. This ability to maintain performance across a wide temperature range makes neoprene timing belts suitable for diverse industrial applications.

3. Chemical Resistance The chemical resistance of neoprene means that it can withstand exposure to various oils, solvents, and other corrosive substances. This property is particularly beneficial in automotive and industrial applications, where exposure to such elements is common.

4. Flexibility and Elasticity Neoprene is inherently flexible, allowing timing belts made from this material to easily navigate around pulleys and gears without compromising performance. Its elastic properties also contribute to excellent power transmission capabilities, reducing slippage and improving efficiency.

5. Noise Reduction When used in mechanical systems, neoprene timing belts can help minimize noise levels. Their design and material composition absorb vibrations, leading to quieter operations, which is particularly valued in consumer applications like home appliances and automotive engines.

Applications of Neoprene Timing Belts

Neoprene timing belts are widely used in a range of applications due to their versatile properties. Some common areas of use include

neoprene timing belt

- Automotive Industry Neoprene timing belts are crucial in the engine timing mechanisms of vehicles. They help synchronize the camshaft and crankshaft, ensuring that the engine valves open and close at the correct times. - Industrial Machinery Many industrial machines, such as conveyor systems, utilize neoprene timing belts for efficient movement and synchronization of components.

- Home Appliances In household items like washing machines and food processors, neoprene timing belts ensure reliable performance and durability.

- Robotics Neoprene timing belts are also employed in various robotic applications, where precise movement and timing are essential for accurate operation.

Maintenance Tips for Neoprene Timing Belts

To ensure the longevity and effectiveness of neoprene timing belts, regular maintenance is essential. Here are a few tips

1. Regular Inspections Routinely check the condition of the timing belt for signs of wear, cracking, or fraying. Early detection can prevent costly breakdowns.

2. Proper Tensioning Ensure that the timing belt is correctly tensioned. A belt that is too loose may slip, while one that is too tight can lead to premature wear.

3. Cleanliness Keep the timing belt area free from debris and contaminants that may cause wear or damage. Regularly clean pulleys and gears to maintain optimal performance.

4. Follow Manufacturer Guidelines Always adhere to the maintenance recommendations provided by the manufacturer, including replacement intervals.

Conclusion

Neoprene timing belts represent an invaluable component in the realm of mechanical systems. With their outstanding durability, flexibility, and resistance to chemicals and temperature, they offer a reliable solution for various applications, from automotive engines to industrial machinery. By understanding the benefits and maintenance of neoprene timing belts, users can maximize their efficiency, prolong their lifespan, and ensure smooth mechanical operation.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025