- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

നവം . 04, 2024 15:17 Back to list

belt v rubber washing machine

The Role of Belts in Rubber Washing Machines

Rubber washing machines are essential in various industries, especially in the production and processing of rubber materials. These machines are designed to clean and prepare rubber for further production or recycling. One of the critical components that ensure the efficient operation of a rubber washing machine is the belt system. This article explores the significance of belts in rubber washing machines, their types, maintenance, and impact on overall performance.

The Role of Belts in Rubber Washing Machines

The choice of belt type significantly impacts the performance of the washing machine. For instance, a well-designed V-belt can improve energy efficiency, leading to lower operational costs. Additionally, the right belt selection ensures that the washing machine operates at optimal speeds, which is crucial for effective cleaning of rubber materials. If the belt is too loose or too tight, it can lead to improper functioning, increasing wear and tear on both the belt and the machine itself.

belt v rubber washing machine

Regular maintenance of the belts in rubber washing machines is essential to ensure their longevity and the machine’s overall performance. Operators should periodically check for signs of wear, such as cracking, fraying, or glazing. A worn-out belt can lead to decreased performance, increased vibration, and ultimately, machine failure. It's advisable to replace belts at the first signs of significant wear to prevent unexpected downtime and costly repairs.

Moreover, proper tensioning of belts is crucial. A belt that is too loose may slip, causing a loss of power transmission, while one that is too tight can cause excess strain on the motor and other components. Therefore, regular inspections and adjustments are needed to maintain the correct tension.

In recent years, advancements in material science have led to the development of more durable and efficient belts for rubber washing machines. These belts demonstrate superior resistance to heat, wear, and chemicals commonly encountered in the rubber processing industry. This innovation not only extends the life of the belts but also enhances the overall operational efficiency of the washing machines.

In conclusion, belts are fundamental to the operation of rubber washing machines. Their role in power transmission, coupled with the importance of maintenance and proper selection, cannot be overstated. As industries continue to seek ways to improve efficiency and reduce costs, the significance of high-quality belts will only grow. Investing in the right belt technology and ensuring regular maintenance can lead to enhanced performance and longevity of rubber washing machines, ultimately benefiting the bottom line in a competitive market.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

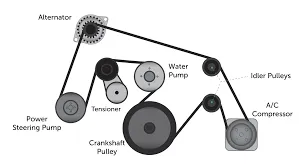

drive belt serpentine belt

NewsMar.07,2025