- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

നവം . 07, 2024 06:26 Back to list

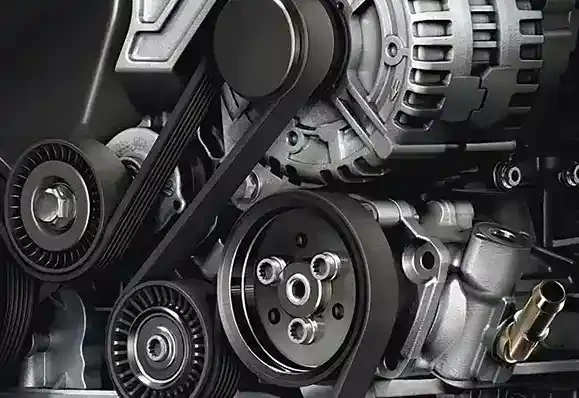

Understanding the Fundamentals and Applications of Belt Drive Systems in Machinery

Understanding Belt Drive Systems A Fundamental Mechanism in Mechanical Engineering

Belt drive systems are an essential component in a wide array of mechanical applications, from automotive engines to industrial machinery. They play a critical role in transferring power between different components within a system. The fundamental principle behind a belt drive is relatively simple a flexible belt is used to connect two or more rotating shafts, allowing for the transmission of motion and force from one shaft to another. This article delves into the working principles, advantages, disadvantages, and applications of belt drive systems.

Working Principle

The operation of a belt drive can be understood through its basic components the belt, the pulleys, and the driven or driving machine parts. The belt, typically made from materials such as rubber, leather, or synthetic composites, is looped around at least two pulleys—one is designated as the driving pulley, while the other is the driven pulley. When the driving pulley rotates, it moves the belt, which in turn rotates the driven pulley. This transfer of motion allows for the efficient conveyance of mechanical energy from one part to another.

The effectiveness of a belt drive relies heavily on friction between the belt and the pulleys. The tighter the belt is on the pulley, the more grip it has, which translates into better energy transfer. Additionally, adjustments can often be made to the tension of the belt to optimize performance, which is an advantage of using belt drives compared to rigid couplings.

Advantages of Belt Drives

Belt drives offer several advantages that make them a popular choice in many applications

1. Flexibility Belt drives can easily accommodate shafts that are spaced apart and can transmit power between non-aligned components. 2. Shock Absorption The elastic nature of belts helps absorb shocks and vibrations, providing a smoother operation than rigid connections. 3. Cost-effectiveness In many cases, belt drives are cheaper to manufacture and install than other systems, such as chain drives or gear systems. 4. Variability By changing the size of the pulleys (i.e., using different diameters), the speed of the driven component can be adjusted easily, providing versatility in design.

belt drive

5. Low Maintenance Generally, belt drives require less maintenance than mechanical systems like chains, which need regular lubrication.

Disadvantages of Belt Drives

Despite their advantages, belt drives also have some inherent drawbacks

1. Slip Depending on the load, belts can slip, which can lead to a loss of efficiency and position. 2. Wear and Tear Over time, belts can suffer from wear, causing them to lose tension or break, which requires replacement. 3. Temperature Sensitivity Many belts can be sensitive to extreme temperatures, which can affect their flexibility and overall performance.

4. Power Limitation Belt drives are generally not suitable for high-power applications compared to gear or chain drives, as they may stretch or break under excessive loads.

Applications of Belt Drives

Belt drives are found in various applications across different sectors. In the automotive industry, they are commonly used for driving accessories such as alternators, water pumps, and air conditioning compressors. In industrial settings, belt drives are prevalent in conveyor systems, manufacturing equipment, and even in household appliances like washing machines.

In conclusion, belt drive systems are a fundamental mechanism in mechanical engineering, providing an efficient and flexible means of power transmission. Understanding their working principles, advantages, and limitations is essential for engineers and technicians alike, as they continue to play a vital role in modern machinery and equipment. Whether in daily life or complex industrial settings, the effectiveness of belt drives remains undeniable, highlighting their relevance in today's technology-driven environment.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025