- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Јун . 28, 2024 15:10 Back to list

High-Performance Elastic Rubber Driving Belts for Smooth Transmission

The Pivotal Role of Round Rubber Drive Belts in Modern Industry

Round rubber drive belts, an essential component in various mechanical systems, play a crucial role in transmitting power from a driving shaft to a driven shaft. These belts, characterized by their circular cross-section and flexible nature, have evolved significantly since their inception, making them indispensable in numerous industrial applications.

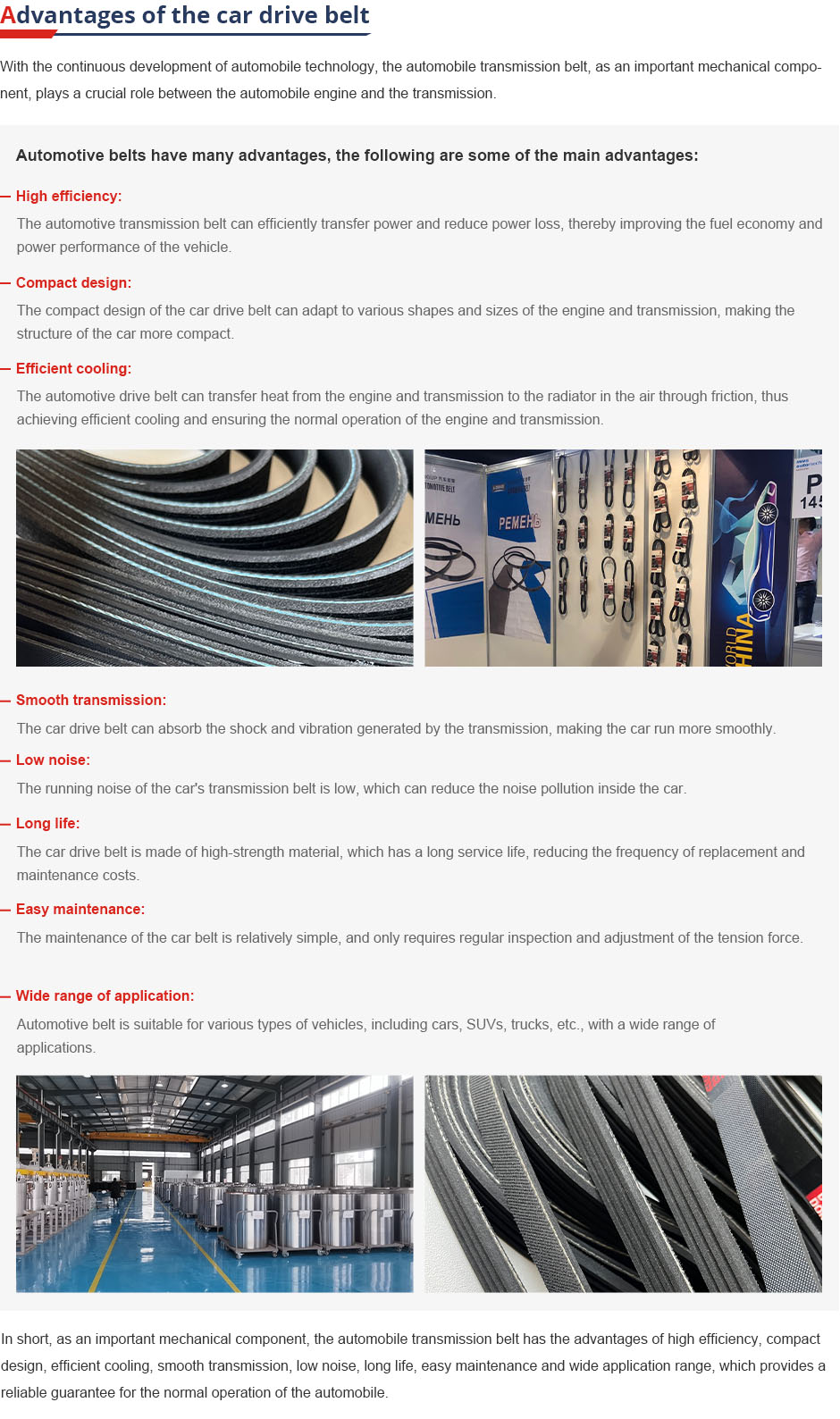

The fundamental principle behind round rubber drive belts is quite simple yet effective. They rely on friction to transfer the rotational energy from the motor or engine to other parts of the machinery. The rubber composition, typically a blend of natural and synthetic rubbers, provides the necessary flexibility and durability, allowing the belt to conform to pulley contours while maintaining grip. The 'round' shape ensures minimal slippage, maximizing efficiency and minimizing energy loss.

One of the most significant advantages of round rubber drive belts is their adaptability. They can be used in a wide range of applications, from automotive engines to agricultural equipment, printing presses, and even food processing machinery. Their ability to transmit power over considerable distances makes them ideal for systems with widely spaced pulleys. Furthermore, they can handle variable loads and speeds, providing a versatile solution for dynamic operational environments.

Maintenance is another area where round rubber drive belts excel. They require less frequent attention compared to other transmission methods like gears or chains. Regular inspection for wear and tension adjustment is usually sufficient to ensure optimal performance Regular inspection for wear and tension adjustment is usually sufficient to ensure optimal performance Regular inspection for wear and tension adjustment is usually sufficient to ensure optimal performance Regular inspection for wear and tension adjustment is usually sufficient to ensure optimal performance

Regular inspection for wear and tension adjustment is usually sufficient to ensure optimal performance Regular inspection for wear and tension adjustment is usually sufficient to ensure optimal performance round rubber drive belts. However, it's crucial to replace worn or damaged belts promptly to prevent system failure.

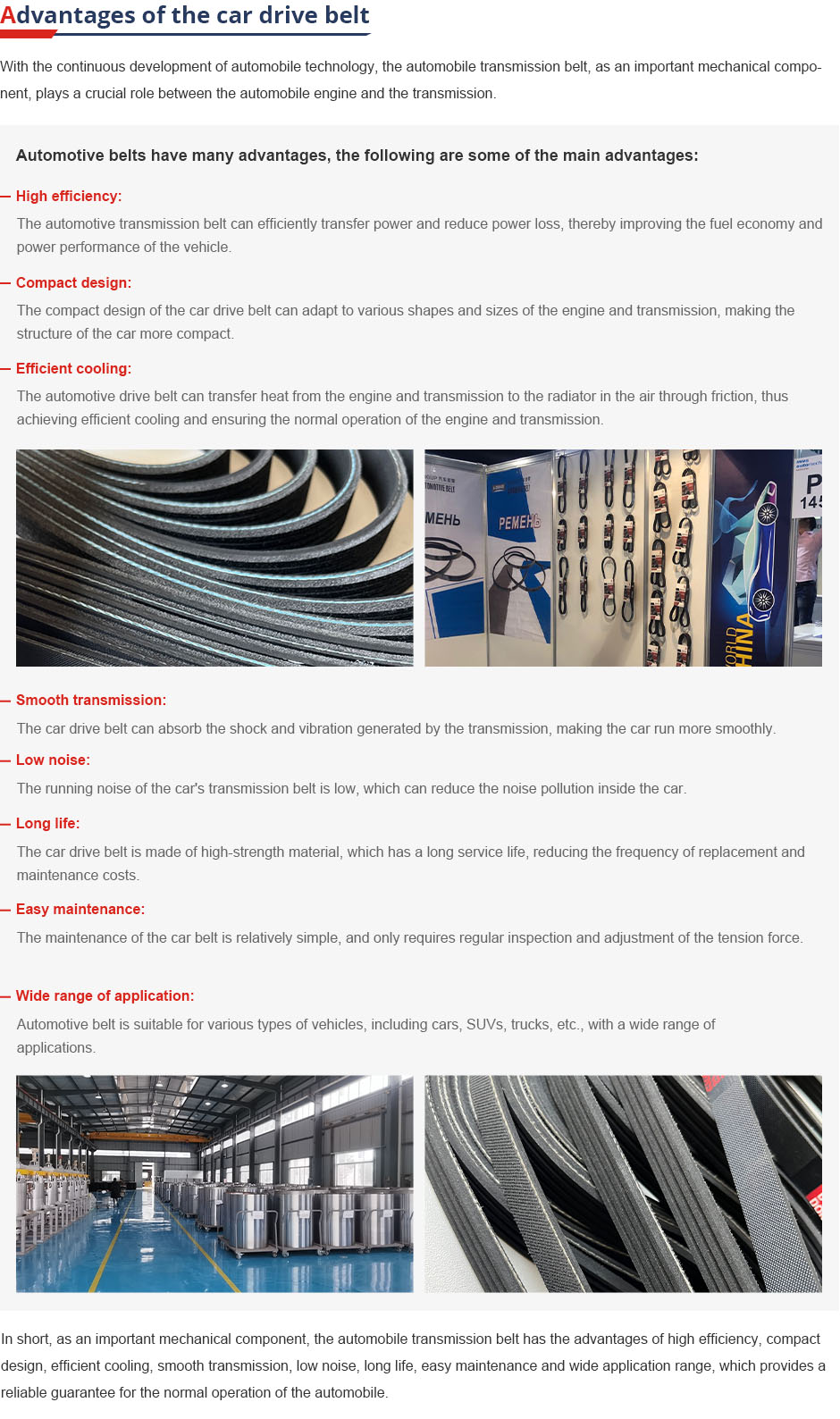

Innovations in material science have led to the development of specialized round rubber drive belts. For instance, V-belts, with their trapezoidal cross-section, offer improved traction and can handle more significant loads. Flat belts, on the other hand, provide a broader contact area, reducing stress and increasing efficiency. Additionally, polyurethane and kevlar-reinforced belts offer enhanced durability and resistance to heat, oil, and abrasion, catering to specific industrial needs.

Despite the emergence of alternative technologies like electric motors and gearboxes, round rubber drive belts continue to hold sway due to their cost-effectiveness, simplicity, and reliability. As we look towards sustainable and efficient manufacturing processes, the role of these belts is likely to remain steadfast.

In conclusion, round rubber drive belts, with their inherent flexibility, adaptability, and robustness, form the backbone of many industrial operations. They embody the essence of practical engineering, seamlessly integrating into complex systems while ensuring smooth and efficient power transmission. As technology advances, these belts will undoubtedly continue to evolve, adapting to new challenges and meeting the demands of a rapidly changing industrial landscape.

round rubber drive belts. However, it's crucial to replace worn or damaged belts promptly to prevent system failure.

Innovations in material science have led to the development of specialized round rubber drive belts. For instance, V-belts, with their trapezoidal cross-section, offer improved traction and can handle more significant loads. Flat belts, on the other hand, provide a broader contact area, reducing stress and increasing efficiency. Additionally, polyurethane and kevlar-reinforced belts offer enhanced durability and resistance to heat, oil, and abrasion, catering to specific industrial needs.

Despite the emergence of alternative technologies like electric motors and gearboxes, round rubber drive belts continue to hold sway due to their cost-effectiveness, simplicity, and reliability. As we look towards sustainable and efficient manufacturing processes, the role of these belts is likely to remain steadfast.

In conclusion, round rubber drive belts, with their inherent flexibility, adaptability, and robustness, form the backbone of many industrial operations. They embody the essence of practical engineering, seamlessly integrating into complex systems while ensuring smooth and efficient power transmission. As technology advances, these belts will undoubtedly continue to evolve, adapting to new challenges and meeting the demands of a rapidly changing industrial landscape.

Regular inspection for wear and tension adjustment is usually sufficient to ensure optimal performance Regular inspection for wear and tension adjustment is usually sufficient to ensure optimal performance

Regular inspection for wear and tension adjustment is usually sufficient to ensure optimal performance Regular inspection for wear and tension adjustment is usually sufficient to ensure optimal performance round rubber drive belts. However, it's crucial to replace worn or damaged belts promptly to prevent system failure.

Innovations in material science have led to the development of specialized round rubber drive belts. For instance, V-belts, with their trapezoidal cross-section, offer improved traction and can handle more significant loads. Flat belts, on the other hand, provide a broader contact area, reducing stress and increasing efficiency. Additionally, polyurethane and kevlar-reinforced belts offer enhanced durability and resistance to heat, oil, and abrasion, catering to specific industrial needs.

Despite the emergence of alternative technologies like electric motors and gearboxes, round rubber drive belts continue to hold sway due to their cost-effectiveness, simplicity, and reliability. As we look towards sustainable and efficient manufacturing processes, the role of these belts is likely to remain steadfast.

In conclusion, round rubber drive belts, with their inherent flexibility, adaptability, and robustness, form the backbone of many industrial operations. They embody the essence of practical engineering, seamlessly integrating into complex systems while ensuring smooth and efficient power transmission. As technology advances, these belts will undoubtedly continue to evolve, adapting to new challenges and meeting the demands of a rapidly changing industrial landscape.

round rubber drive belts. However, it's crucial to replace worn or damaged belts promptly to prevent system failure.

Innovations in material science have led to the development of specialized round rubber drive belts. For instance, V-belts, with their trapezoidal cross-section, offer improved traction and can handle more significant loads. Flat belts, on the other hand, provide a broader contact area, reducing stress and increasing efficiency. Additionally, polyurethane and kevlar-reinforced belts offer enhanced durability and resistance to heat, oil, and abrasion, catering to specific industrial needs.

Despite the emergence of alternative technologies like electric motors and gearboxes, round rubber drive belts continue to hold sway due to their cost-effectiveness, simplicity, and reliability. As we look towards sustainable and efficient manufacturing processes, the role of these belts is likely to remain steadfast.

In conclusion, round rubber drive belts, with their inherent flexibility, adaptability, and robustness, form the backbone of many industrial operations. They embody the essence of practical engineering, seamlessly integrating into complex systems while ensuring smooth and efficient power transmission. As technology advances, these belts will undoubtedly continue to evolve, adapting to new challenges and meeting the demands of a rapidly changing industrial landscape. Share:

Latest news

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025