- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Дек . 25, 2024 09:40 Back to list

Understanding Flat and V Belts in Mechanical Systems for Optimal Performance and Efficiency

Understanding Flat and V Belts Applications and Differences

Belts are essential components in mechanical systems, providing a means of power transmission between rotating shafts. Among various types of belts, flat belts and V belts are two of the most commonly used in various industries. Understanding the characteristics, applications, and differences between these two types of belts is crucial for selecting the right one for specific mechanical needs.

Flat Belts

Flat belts are typically made from materials such as leather, rubber, or fabric, and are characterized by their rectangular cross-section. They are designed to transmit power over long distances and are often found in applications where the pulleys are widely spaced. The flat design allows them to run smoothly over pulleys without the risk of slipping, provided there is sufficient tension.

One of the main advantages of flat belts is their ability to operate at high speeds. They can effectively transmit power in applications such as conveyor systems, textile machinery, and agricultural implements. Flat belts are particularly useful in situations where the ratio of speeds is important, as they can be utilized in systems with varying diameters of pulleys.

However, flat belts do have some limitations. They are not as efficient in power transmission as V belts, primarily because the contact area between the belt and the pulley is less compared to that of V belts. This can lead to increased wear and reduced lifespan under heavy loads. Additionally, flatter belts require more frequent adjustment and tensioning to maintain proper operation, as they can stretch over time.

V Belts

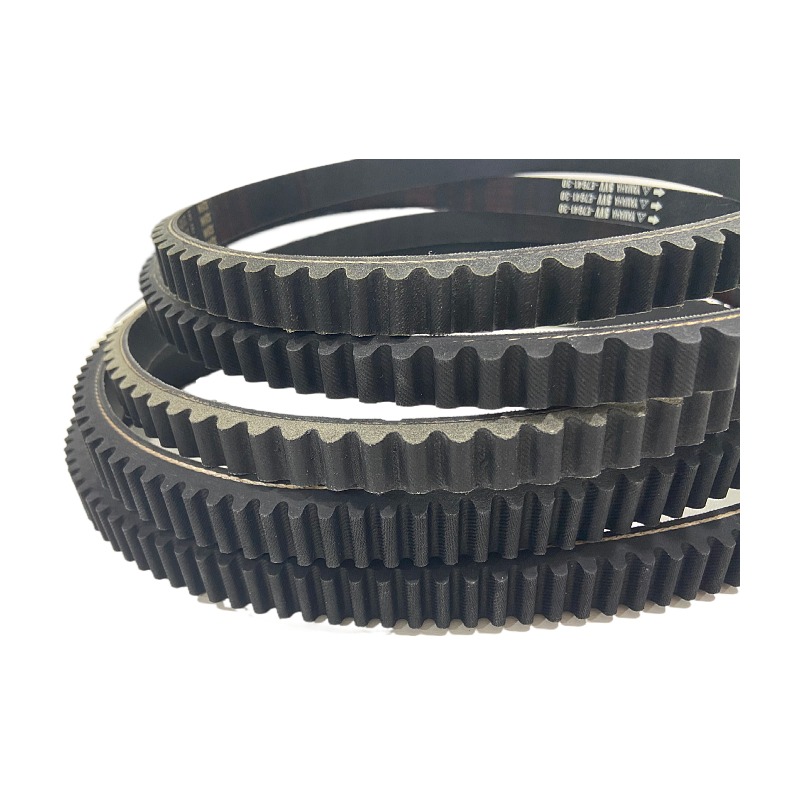

flat and v belt

V belts, on the other hand, have a trapezoidal cross-section, which allows them to fit snugly into the grooves of the pulleys. This design provides better grip and reduces the chances of slipping, making V belts highly efficient for power transmission. The wedged shape of V belts enables them to transmit more power than flat belts, especially in compact spaces where pulleys are closer together.

V belts are widely used in various applications, including automotive engines, appliances, and industrial machinery. Their efficient design allows for higher torque transmission and reduced slippage, which means they can handle heavier loads than flat belts. Moreover, they require less tensioning and maintenance over time, making them a more user-friendly option.

One of the notable advantages of V belts is their ability to compensate for misalignment of shafts. Because they can ride deeper into the grooves of the pulleys, V belts are less affected by small misalignments compared to flat belts. This characteristic enhances their durability and performance in real-world applications.

Key Differences

The fundamental differences between flat and V belts stem from their design, performance, and applications. While flat belts have a rectangular shape and are suitable for long-distance power transmission, V belts feature a trapezoidal design that allows for better grip and power efficiency. V belts are generally preferred in applications requiring higher loads and space constraints.

Another notable difference is in maintenance and longevity. Flat belts require more regular adjustments and can be prone to wear under heavy loads, while V belts demand less maintenance and provide a longer service life under similar conditions.

In conclusion, both flat and V belts have their unique properties, advantages, and disadvantages that make them suited for specific applications. Understanding these differences is essential for engineers and technicians in selecting the appropriate belt for their mechanical systems. Whether in industrial machines, vehicles, or home appliances, choosing the right belt can significantly impact the efficiency and longevity of the equipment.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025