- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Сеп . 01, 2024 10:54 Back to list

Diesel Engine Belt - High-Performance and Durable Solutions

Understanding Diesel Engine Belts Their Importance and Functionality

Diesel engines are renowned for their durability and efficiency, making them a preferred choice in various applications ranging from transportation to industrial machinery. At the heart of these engines lies a system of belts that plays a pivotal role in their operation. Understanding diesel engine belts, their types, and their functionalities can enhance your knowledge about engine maintenance and performance.

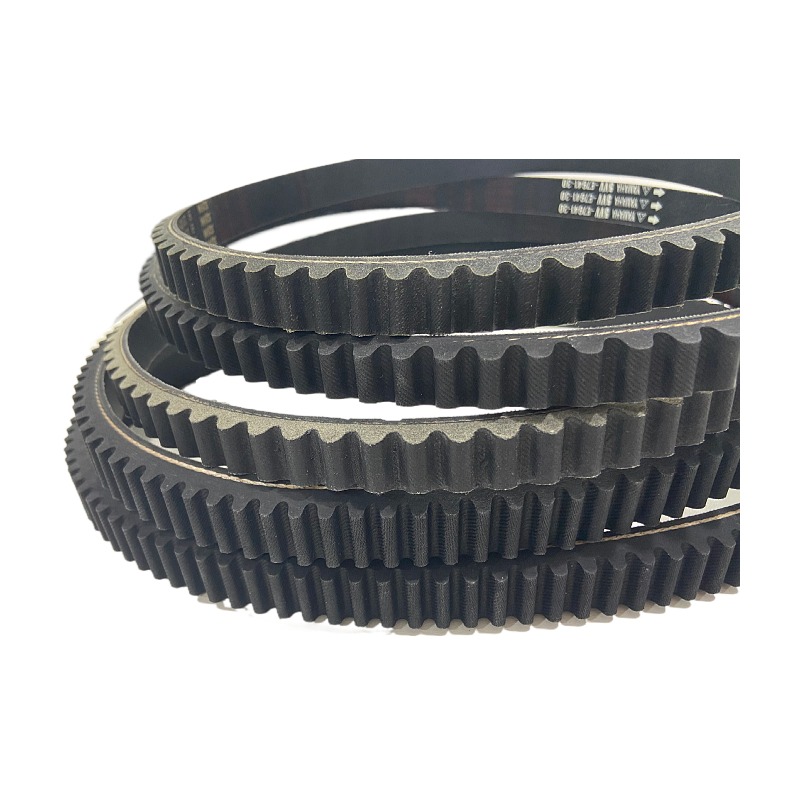

Diesel engine belts are rubber strips designed to transfer power between different components of the engine. The most common types of belts in diesel engines include the serpentine belt and the timing belt. Each type has a specific function, and their integrity is crucial for the seamless operation of the engine.

The serpentine belt, often referred to as a drive belt, is essential for powering multiple peripheral devices such as the alternator, water pump, power steering pump, and air conditioning compressor. Its flat, elongated design allows it to wrap around various pulleys, and any wear or damage to this belt can lead to a loss of power to these components, resulting in potential overheating or electrical failure. Regular inspection of the serpentine belt is vital to prevent unexpected breakdowns.

diesel engine belt

On the other hand, the timing belt is responsible for synchronizing the rotation of the crankshaft and camshaft. This synchronization ensures that the engine’s valves open and close at the correct times during each engine cycle. Unlike the serpentine belt, the timing belt is a critical component for the engine’s internal operations. Any failure of the timing belt can lead to severe engine damage, often referred to as a timing belt failure. Therefore, manufacturers usually recommend a specific replacement interval, typically every 60,000 to 100,000 miles, depending on the vehicle.

In addition to the serpentine and timing belts, some diesel engines may also use additional belts for specific applications, such as the V-belt, which is narrower and used for similar functions as the serpentine belt but on older engine models.

Maintaining these belts is crucial for the overall performance and longevity of a diesel engine. Regular checks for signs of wear, cracks, or fraying can prevent more significant issues down the road. Ensuring proper tension on these belts is also important; too loose can lead to slippage, while too tight can cause undue stress on the components.

In conclusion, diesel engine belts are essential components that ensure the engine operates smoothly and efficiently. Understanding their functions and maintaining them can save time and money while enhancing the overall performance of the engine. Regular inspection and timely replacement of these belts can help ensure that your diesel engine runs at its best.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025