- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Ное . 25, 2024 12:42 Back to list

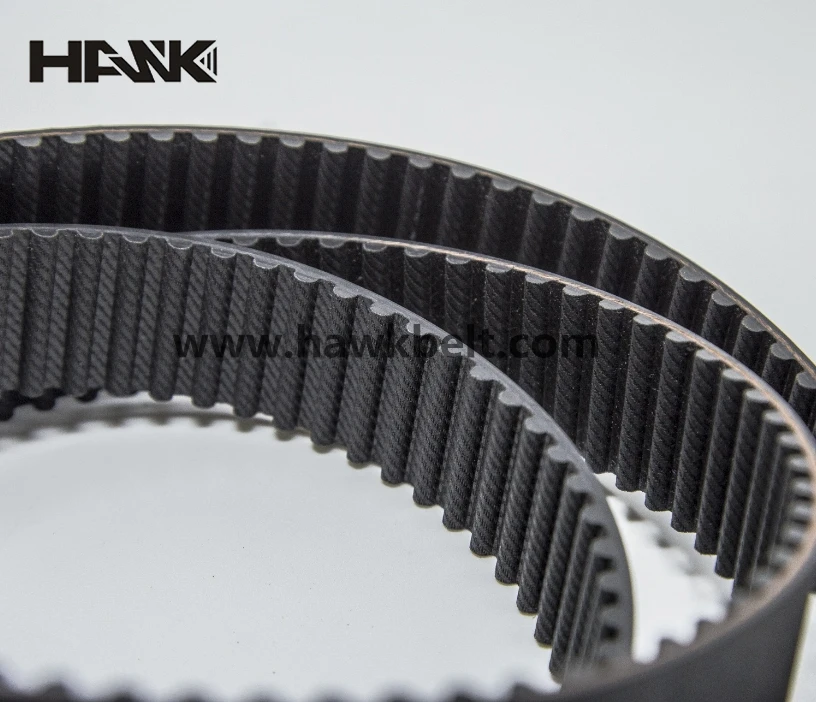

adjustable fan belt

The Importance of Adjustable Fan Belts in Automotive Applications

In the world of automotive engineering, the reliability and efficiency of vehicles greatly depend on the various parts that work in harmony to ensure smooth operation. One critical component that often goes unnoticed is the fan belt, specifically, the adjustable fan belt. While it may seem like a simple rubber band, the fan belt plays a crucial role in powering essential systems within the vehicle, such as the cooling system, alternator, and power steering.

What is an Adjustable Fan Belt?

An adjustable fan belt is designed to maintain the correct tension within an automotive system. Unlike fixed belts, adjustable fan belts come with features that allow for tension modification. This is particularly important as belts can stretch or wear over time, leading to a decrease in performance or even failure. By being adjustable, mechanics can ensure that the belt operates at the optimal tension, enhancing the lifespan of the belt and the efficiency of the vehicle.

The Function of the Fan Belt

The primary function of the fan belt is to connect the engine’s crankshaft to the various systems it drives. This includes the water pump, which circulates coolant to prevent the engine from overheating, and the alternator, which generates electricity to power the vehicle's electrical systems. Additionally, the fan belt may also engage components like air conditioning compressors and steering pumps.

In essence, the fan belt is like the lifeline of the engine bay, transmitting power from the engine to the vital systems that keep the vehicle operational. If the belt were to fail, it could lead to overheating or a loss of electrical power, resulting in severe engine damage or a complete breakdown.

Why Adjustable Fan Belts Are Advantageous

adjustable fan belt

1. Tension Management As mentioned earlier, the tension of a fan belt must be just right. If it’s too loose, it can slip off or not transfer sufficient power; if it’s too tight, it can strain the engine components. An adjustable fan belt allows mechanics to fine-tune the tension as needed, even after installation.

2. Increased Longevity With the ability to adjust the tension, adjustable fan belts tend to have longer lifespans compared to their fixed counterparts. Regularly adjusting the belt to maintain optimal tension reduces wear and tear, avoiding premature breakdowns and the need for frequent replacements.

3. Enhanced Efficiency Properly adjusted belts contribute to better fuel efficiency. A belt that operates at the right tension transmits energy more efficiently, reducing the workload on the engine. This translates to savings at the fuel pump and lower greenhouse gas emissions.

4. Versatility Adjustable fan belts are versatile and can be used in a wide range of vehicles, from standard passenger cars to heavy-duty trucks. They accommodate various engine sizes and complexities, making them a popular choice among automakers and mechanics alike.

5. Ease of Maintenance For mechanics and DIY enthusiasts, adjustable fan belts simplify maintenance. Instead of replacing a belt at the first signs of wear, adjustments can easily be made to extend the belt's life. This can save time and money for both staff and vehicle owners.

Conclusion

In conclusion, the adjustable fan belt is a vital component in modern automotive design, allowing for improved performance, efficiency, and longevity. While often overshadowed by more prominent parts, its role cannot be understated. The ability to adjust tension to optimal levels helps prevent issues that could lead to significant vehicle problems. As automotive technology continues to evolve, incorporating more adjustable components like the fan belt can lead to even greater advancements in vehicle performance and reliability. For anyone interested in vehicle maintenance, understanding the critical role of the adjustable fan belt is essential for ensuring the health and longevity of their automotive investment.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025