- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Lap . 11, 2024 08:24 Back to list

synchronous belt drive

Understanding Synchronous Belt Drives A Comprehensive Overview

Synchronous belt drives have become an essential component in various mechanical and industrial applications due to their efficiency, reliability, and precision in power transmission. Unlike traditional belt drives, which rely on friction to transmit power, synchronous belt drives utilize a toothed design that engages with corresponding pulleys, allowing for synchronous movement of the drive components. This article explores the workings, advantages, applications, and considerations for using synchronous belt drives.

How Synchronous Belt Drives Work

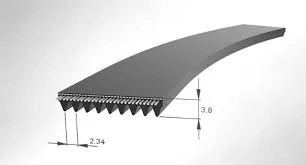

At the heart of a synchronous belt drive system is the synchronous belt, made from a combination of materials including rubber, polyurethane, or neoprene, reinforced with fiber to enhance strength and durability. The belt features regularly spaced teeth that mesh with matching grooves on the pulleys. This design prevents slippage, ensuring that the pulleys rotate in perfect synchronization.

When the drive motor turns the pulley, the corresponding teeth of the synchronous belt engage the toothed pulleys, transmitting power with precision. The absence of slippage not only improves efficiency but also allows for accurate positioning in applications where timing is critical, such as robotics and CNC machinery.

Advantages of Synchronous Belt Drives

1. High Efficiency Synchronous belt drives achieve efficiency ratings of over 95%, reducing energy losses when compared to traditional friction-based belt systems. This high efficiency translates into lower operational costs for businesses.

2. Precision Timing The inherently positive engagement between the belt and pulley eliminates the potential for slippage. This characteristic is particularly beneficial in applications requiring precise speed and timing control, such as linear actuators and automated assembly lines.

3. Low Maintenance Synchronous belts tend to require less maintenance compared to other drive systems. They do not require tensioning adjustments as frequently, and their durable materials resist wear and tear, reducing downtime.

4. Versatility Synchronous belt drives can be designed for a variety of applications ranging from high-speed machinery to small-scale devices. Their adaptability makes them suitable for industries including automotive, aerospace, agriculture, and manufacturing.

5. Quiet Operation Due to the meshing design, synchronous belts operate quietly compared to chain drives and other mechanical systems. This characteristic is advantageous in settings where noise reduction is desirable.

synchronous belt drive

Applications of Synchronous Belt Drives

Synchronous belt drives find applications in numerous sectors. They are commonly used in

- Automated Machinery Robotics and conveyor systems leverage synchronous belt drives for accurate positioning and reliable motion control. - CNC Machines In manufacturing, synchronous belts facilitate precise movement for cutting and milling processes. - Fitness Equipment Many exercise machines utilize synchronous belts to ensure smooth and consistent movement. - Automotive Systems Synchronous belts are also prevalent in vehicles, connecting components such as camshafts and crankshafts to ensure optimal engine performance.

Considerations for Use

While synchronous belt drives offer numerous advantages, there are considerations before their implementation

1. Load Capacity It is essential to select a synchronous belt that can handle the required load for the application. Underrating can lead to premature failure.

2. Environmental Factors The material of the belt may be affected by extreme temperatures, oil, or chemicals, so selecting the correct material for the operational environment is crucial.

3. Initial Costs While better performance and lower maintenance costs can offset the initial investment, synchronous belt drives may have a higher upfront cost compared to traditional systems.

4. Installation Alignment Proper alignment during installation is critical to prevent wear and ensure optimal performance. Poor alignment can lead to increased noise, abrasion, and a reduced lifespan of the belt and pulleys.

Conclusion

Synchronous belt drives have revolutionized the way mechanical power is transmitted in various industries. With their high efficiency, precision timing, and low maintenance requirements, these systems continue to gain popularity across diverse applications. Understanding their advantages and potential limitations allows engineers and businesses to make informed decisions, ensuring that they leverage the full potential of synchronous belt drives in their operations. As technology advances, the role of synchronous belts is likely to expand even further, paving the way for innovations in motion control and mechanization.

-

Reliable Diesel Engine Belts & Tensioners for Optimal Performance

NewsAug.07,2025

-

23100-KVB-901 Drive Belt for Honda VARIO | OEM Performance

NewsAug.06,2025

-

Variable Belt Drive AI Optimized for Efficiency

NewsAug.05,2025

-

High-Quality Tensioner Belt Pulley - Durable & Efficient

NewsAug.03,2025

-

Premium Timing Belt Factory | AI-Optimized Solutions

NewsAug.02,2025

-

Heat Joining Drive Belt | High-Durability Fusion Solution

NewsJul.31,2025