- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Lap . 13, 2024 12:44 Back to list

small machine belts

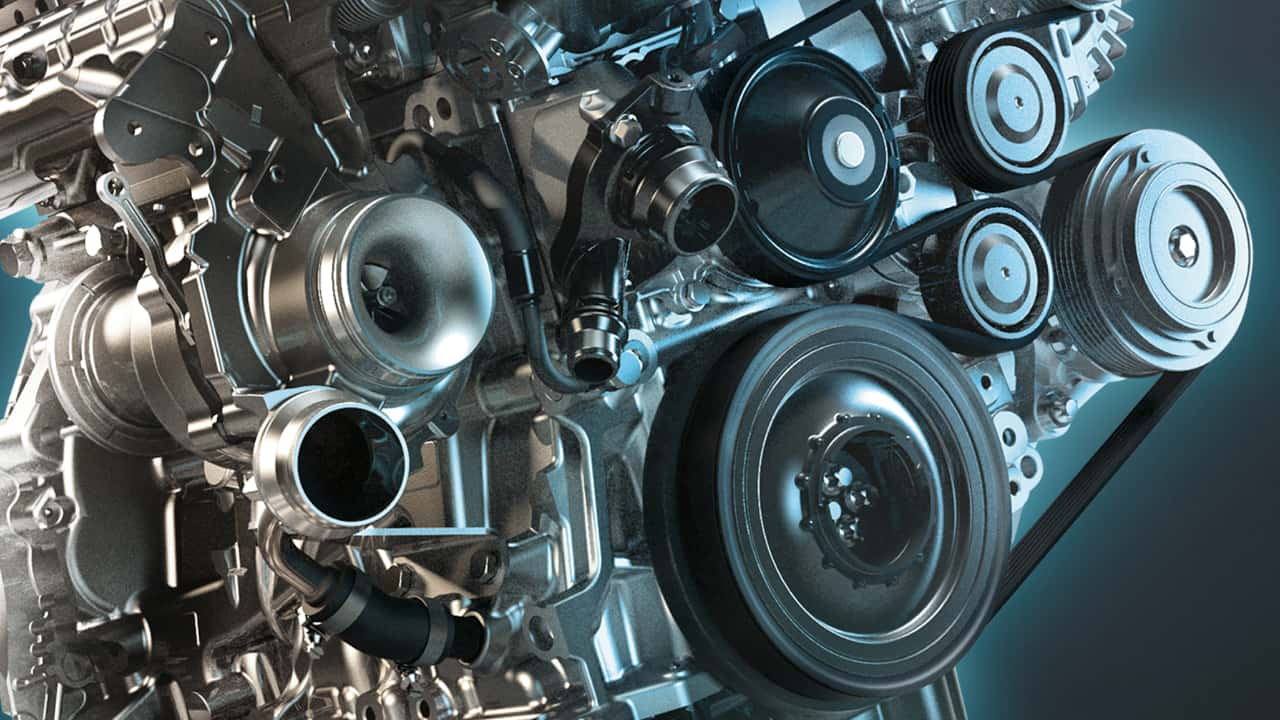

The Importance of Small Machine Belts in Modern Industry

Small machine belts play a crucial role in the functioning of various machinery across numerous industries. From simple household appliances to complex industrial equipment, these belts are essential for the efficient transfer of power and motion. Understanding the significance of small machine belts can help in appreciating their impact on technology and productivity in contemporary society.

Small machine belts are typically made from materials such as rubber, polyurethane, or leather, designed to withstand wear and tear while providing optimal flexibility. Their primary purpose is to transmit motion and power between different components of a machine, such as motors, pulleys, and wheels. This seemingly simple function is vital for the overall operation of machinery, ensuring that everything works in harmony.

One of the key benefits of small machine belts is their ability to maintain consistent tension. This is particularly important in applications where precision is critical. For example, in CNC machines and 3D printers, small belts are integral to ensuring that the moving parts operate smoothly and accurately. A slip or misalignment can lead to significant errors, impacting product quality and efficiency.

In addition to ensuring precision, small machine belts contribute to the overall durability and longevity of machinery

. By efficiently transferring energy, they minimize wear on other components, leading to reduced maintenance costs over time. This is a significant advantage for industries that rely on continuous operation and cannot afford lengthy downtimes for repairs.small machine belts

Moreover, small machine belts are versatile in their applications. They can be found in various devices such as printers, air conditioning units, conveyor systems, and even automotive engines. This versatility means that understanding and optimizing the use of small machine belts can lead to improved efficiency across many sectors.

In recent years, advancements in material science and engineering have led to the development of high-performance belts that can withstand extreme conditions, making them even more reliable. For instance, some modern belts are designed to operate in high-temperature environments or under heavy loads without sacrificing performance. These advancements are particularly beneficial for industries such as manufacturing and logistics, where the demands on machinery are constantly increasing.

As industries evolve, the importance of maintaining machinery with the right components becomes more evident. Regular inspection and timely replacement of small machine belts are essential to preventing breakdowns and ensuring optimal functioning. Companies that prioritize this practice often find that they can achieve higher productivity and efficiency, ultimately leading to better profitability.

In summary, small machine belts are more than just simple components; they are foundational elements that contribute to the functionality, efficiency, and reliability of various machines. Understanding their significance can help industries optimize their operations, reduce costs, and improve overall productivity. As technology continues to advance, the role of small machine belts will only become more important, making it imperative for businesses to pay attention to these essential components. By investing in high-quality small machine belts and adhering to maintenance best practices, companies can ensure that they remain competitive in an ever-evolving industrial landscape.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025