- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Lap . 05, 2024 05:15 Back to list

for cummins engine belt

Understanding the Importance of Belts in Cummins Engines

Cummins engines are renowned for their durability and performance across various industries, including transportation, construction, and agriculture. A critical component of these engines is the belts that facilitate essential functions. This article delves into the significance of belts in Cummins engines, their types, maintenance tips, and their impact on engine performance.

The Role of Belts in Cummins Engines

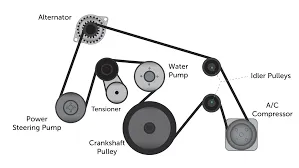

Belts in Cummins engines primarily serve several essential purposes, including driving pulleys that control various engine components such as the alternator, water pump, and air conditioning compressor. These belts convert rotational energy from the engine’s crankshaft to these critical devices, helping maintain optimal engine operation.

1. Accessory Drive Belt Also known as a serpentine belt, this single belt can drive multiple accessories. In Cummins engines, it’s essential for powering the alternator, which charges the battery and powers electrical systems, as well as the water pump, which regulates engine temperature by cooling.

2. Timing Belt The timing belt is crucial for synchronizing the rotation of the crankshaft and camshaft, ensuring that the engine's valves open and close at the proper times during each cylinder’s intake and exhaust strokes. Proper timing is vital for maximizing engine efficiency and performance.

3. V-Belts These belts are typically used for older Cummins engine models and can drive components like the air conditioning compressor and power steering pump. V-belts are characterized by their V shape, which allows for better grip on the pulleys.

Importance of Regular Maintenance

Regular maintenance of the belts in Cummins engines is paramount to ensuring longevity and peak performance. Over time, belts can suffer wear and tear from heat, dirt, and engine vibrations. Here are some maintenance tips

for cummins engine belt

1. Visual Inspections Regularly inspect belts for signs of cracking, fraying, or glazing. Early detection can prevent unexpected failures and costly repairs.

2. Proper Tension Ensuring that belts are correctly tensioned is crucial. A belt that is too loose may slip and fail to drive the accessories effectively, while one that is too tight can cause premature wear and tear on bearings.

3. Replacement Schedule Follow the manufacturer’s recommendations for replacing belts. Timing belts, in particular, require strict adherence to replacement intervals because failure can result in significant engine damage.

4. Environment Considerations If the engine operates in harsh environments, such as extreme temperatures or dusty conditions, more frequent inspections and replacements may be necessary.

Impact on Performance

The condition of belts can directly impact the performance and efficiency of Cummins engines. A worn or damaged belt can lead to a range of issues, including

- Power Loss If the alternator isn’t receiving sufficient power due to a slipping belt, the battery may not charge properly, leading to electrical failures. - Overheating A malfunctioning water pump due to a faulty belt can result in overheating, which can cause severe engine damage. - Reduced Fuel Efficiency An inefficiently running engine due to accessory failures can lead to increased fuel consumption, impacting overall operational costs.

Conclusion

Belts play a vital role in the effective operation of Cummins engines, influencing performance, efficiency, and longevity. Understanding the function of different belt types, engaging in regular maintenance practices, and being aware of the signs of wear can help keep your engine running smoothly. Whether it’s a construction site rig, a delivery truck, or an agricultural machine, maintaining the belts will not only extend the life of the engine but also enhance its reliability and efficiency. For those invested in maximizing performance and minimizing downtime, paying attention to belt maintenance is a small but critical step in engine management.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025