- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ຕ.ລ. . 19, 2024 15:46 Back to list

molded ribbed poly v belts

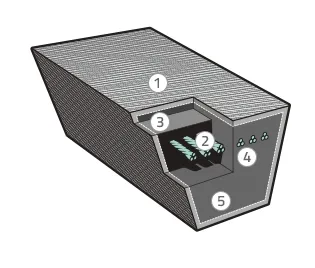

The Advantages of Molded Ribbed Poly V Belts

Molded ribbed poly V belts are an essential component in various industrial and automotive applications, offering significant advantages over traditional belt designs. These belts are characterized by their unique structure, which includes multiple ribs and a flexible design, making them ideal for high-performance applications.

Structure and Design

Molded ribbed poly V belts are designed with several longitudinal ribs that increase the contact surface area with the pulleys. This design not only enhances the grip but also minimizes slippage, which is a common issue with conventional V belts. The ribs increase the flexibility of the belt, allowing it to navigate around smaller pulleys and bends without compromising on performance. Additionally, the polyvinyl (poly) material used in these belts provides durability, resistance to wear, and protection against environmental factors.

Enhanced Performance

One of the primary benefits of molded ribbed poly V belts is their ability to transfer power efficiently. The combination of the ribbed design and the flexibility of the poly material minimizes energy loss during power transmission. This increased efficiency is vital for machinery and automotive functions where performance is crucial. Moreover, these belts can handle higher speeds and loads compared to their traditional counterparts, making them suitable for high-performance engines and industrial machinery.

Versatility

Molded ribbed poly V belts are highly versatile, making them suitable for a wide range of applications. They are commonly used in automotive systems, such as alternators, water pumps, and power steering systems. In industrial settings, these belts are utilized in conveyor systems, HVAC machinery, and material handling equipment. Their adaptability allows manufacturers to meet varying performance needs across different industries.

molded ribbed poly v belts

Reduced Noise and Vibration

Another advantage of molded ribbed poly V belts is the reduction of noise and vibration during operation. Traditional V belts often produce significant noise due to slippage or misalignment. In contrast, molded ribbed poly V belts maintain a tighter fit on the pulleys, which helps minimize vibration and sound. This feature not only improves the operating environment, particularly in noise-sensitive settings, but also contributes to the longevity of the machinery by decreasing wear and tear.

Maintenance and Longevity

Maintenance is a critical factor in ensuring the efficiency of belt-driven systems. Molded ribbed poly V belts generally require less maintenance than traditional belts. Their robust construction and resistance to stretching and cracking mean that they can last longer, reducing the frequency of replacements. Additionally, many manufacturers incorporate advanced materials that enhance resistance to contaminants, oils, and other substances that could degrade belt performance.

Environmentally Friendly Options

As sustainability becomes an increasing concern in manufacturing, molded ribbed poly V belts also offer eco-friendly materials and production methods. Many brands are focusing on developing belts using recycled materials and environmentally friendly manufacturing processes. This shift not only helps reduce the environmental impact but also meets consumer demands for sustainable products.

Conclusion

In conclusion, molded ribbed poly V belts are a superior choice for a variety of applications due to their innovative design, enhanced performance, and durability. Their ability to reduce noise and vibration, along with low maintenance requirements, makes them a practical option for both automotive and industrial uses. As manufacturers continue to prioritize efficiency and sustainability, the popularity of molded ribbed poly V belts is likely to grow. By investing in these advanced belts, businesses can improve productivity and performance while also meeting environmental standards. Whether for precision machinery or everyday vehicles, molded ribbed poly V belts stand out as a reliable solution for modern power transmission needs.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025