- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ທ.ວ. . 17, 2024 18:42 Back to list

drive belt manufacturers

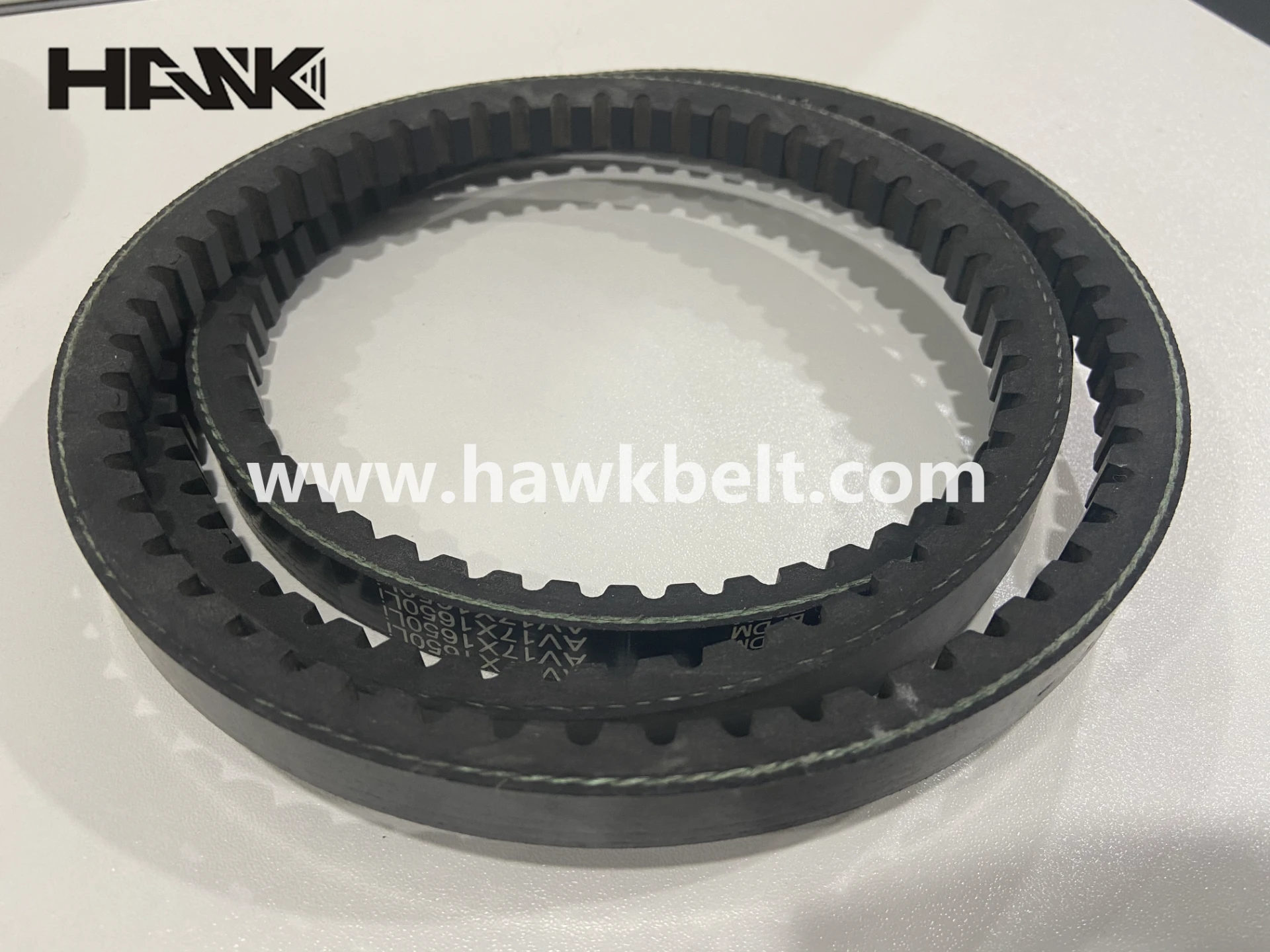

Understanding Drive Belt Manufacturers Quality and Innovation in Motion

In the world of automotive and industrial machinery, drive belts serve as essential components responsible for transferring power from one part of a machine to another. They play a crucial role in ensuring that various systems function smoothly and efficiently. Drive belt manufacturers are the backbone of this industry, providing high-quality products that meet the ever-evolving demands of technology and performance.

The Importance of Drive Belts

Drive belts, whether they are serpentine belts, timing belts, or V-belts, have a significant influence on the efficiency and reliability of machinery. They are utilized in a variety of applications, including vehicles, conveyors, and industrial machines. A well-functioning drive belt minimizes the risk of slippage, reduces wear and tear on components, and contributes to lower energy consumption. Consequently, the quality of these belts is paramount, and it is here that drive belt manufacturers shine.

Key Features of Drive Belt Manufacturers

1. Innovation in Design and Materials Modern drive belt manufacturers invest heavily in research and development to create belts that are not only durable but also fit the specific requirements of different applications. This includes the use of advanced materials such as synthetic rubber compounds, which enhance strength and flexibility. Manufacturers are also exploring innovative designs, such as tooth configurations in timing belts that improve precision and performance.

2. Customization and Variety Different industries have different needs. Drive belt manufacturers often provide customized solutions to meet specific requirements. This might include variations in size, material composition, or even the integration of special features such as noise reduction or increased resistance to environmental factors like heat and oil. A wide selection of products allows customers to choose the belt that best suits their operational needs.

drive belt manufacturers

3. Adherence to Standards Drive belt manufacturers must comply with stringent industry standards to ensure that their products are safe and effective. This includes testing belts for strength, durability, and performance under various conditions. Many manufacturers achieve certifications such as ISO 9001, which signifies a commitment to quality management systems. Adhering to such standards not only ensures product reliability but also builds trust with customers.

4. Sustainability Practices As businesses become more aware of their environmental impact, many drive belt manufacturers are adopting sustainable practices. This includes using recyclable materials in production, reducing waste in manufacturing processes, and promoting energy-efficient products. Customers today are increasingly inclined to support companies that prioritize sustainability, making this a crucial aspect of modern manufacturing.

5. Technical Support and Expertise The complexity of machinery requires a deep understanding of how components interact. Many drive belt manufacturers provide not only high-quality products but also technical support to help clients select the right belts and ensure proper installation. This expertise can prove invaluable, particularly for businesses that rely heavily on machinery for their operations.

The Future of Drive Belt Manufacturing

The landscape of drive belt manufacturing is continually evolving. With the rise of electric vehicles and advanced automation, there is an increasing demand for belts that can perform under unique conditions. Manufacturers are poised to embrace the challenges of the future by investing in smart materials and incorporating digital technologies into their production processes. The integration of IoT (Internet of Things) can pave the way for smart belts that provide real-time feedback on performance, further enhancing efficiency and maintenance.

Conclusion

Drive belt manufacturers play a critical role in the smooth operation of various industries by producing high-quality, innovative products that meet the needs of their customers. As technology continues to advance, these manufacturers must remain adaptable, focusing on quality, customization, and sustainability. By prioritizing these elements, they not only ensure their continued success but also contribute positively to the industries they serve and the environment at large. The evolution of drive belts is a testament to the vital relationship between manufacturing and technological advancement, and it promises a future filled with potential for both producers and users alike.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025