- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Aug . 17, 2024 09:12 Back to list

Understanding the Importance of Machine Timing Belts in Engine Performance and Maintenance

Understanding Machine Timing Belts Essential Components for Precision Engineering

Timing belts play a fundamental role in the operation of various machines, especially within the fields of manufacturing and automotive engineering. These essential components are designed to synchronize the rotation of the crankshaft and the camshaft, ensuring that the engine's valves open and close at the appropriate times during each cylinder's intake and exhaust strokes. However, their applications extend well beyond automotive engines, finding importance in a wide array of machinery, including industrial equipment, robotics, and conveyor systems.

The Anatomy of a Timing Belt

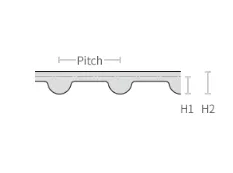

A timing belt is typically made from a durable rubber composite, reinforced with fibers to enhance its strength and flexibility. The interior of the belt features a series of teeth or notches that fit into corresponding grooves on the pulleys it engages with. This tooth design is critical, as it prevents slippage and allows for precise transfer of rotational motion, ensuring that all components within the machine operate in harmony.

Types of Timing Belts

Timing belts come in various types, suited for different requirements. The most common types include

1. Standard Timing Belts Often used in low-power applications, these belts are ideal for machines where low torque and high accuracy are required.

2. High Torque Timing Belts Designed for heavy-duty applications, these belts are reinforced with additional materials to withstand greater stress and prevent wear.

3. Synchronous Belts These belts are specifically engineered to maintain a constant distance between driven components, making them ideal for precision machinery.

4. Specialty Belts Custom-designed belts cater to specific industries or applications, such as those resistant to temperature extremes or chemicals.

machine timing belt

Importance of Machine Timing Belts

The significance of timing belts in machinery cannot be overstated. Here are several key reasons why they are indispensable

1. Precision Timing belts ensure that machinery operates with high precision, which is essential in manufacturing environments where tolerances are tight.

2. Reliability These belts require minimal maintenance compared to chains or gears. Their design minimizes wear and tear, leading to longer service life and reliable performance.

3. Noise Reduction Unlike metal gears, timing belts operate quietly, reducing the overall noise levels in workplaces, which is particularly beneficial in settings requiring a quiet atmosphere.

4. Efficiency Timing belts provide smooth and efficient power transmission, which improves the overall performance of a machine. This efficiency translates into energy savings and reduced operational costs.

Maintenance and Replacement

To maximize the lifespan and functionality of a timing belt, regular maintenance is necessary. This includes inspection for signs of wear, such as cracks or fraying, and ensuring that the belt is properly tensioned. Depending on the manufacturer's recommendations and the specific application, timing belts should be replaced every few years or after a certain number of operating hours to prevent the risk of failure, which can lead to significant damage and costly downtime.

Conclusion

In conclusion, machine timing belts are integral components that contribute to the efficient and reliable operation of various types of machinery. Their ability to synchronize mechanical processes with precision makes them indispensable in numerous applications. As technology continues to advance, the design and materials used in timing belts are also evolving, promising even greater efficiency and reliability for the future of industrial and automotive engineering. Understanding the significance of these components is crucial for anyone involved in machine maintenance, operation, or design, highlighting the importance of keeping them in optimal condition.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025