- Arabice

- Gallica

- Russian

- hispanice

- Portuguese

- Turcicum

- Armenian

- Anglicus

- Albanian

- Aethiopica

- Azerbaijani

- Basque

- Belarusian

- Bengalica

- Bosnian

- Bulgarica

- Catalan

- Cebuano

- Corsica

- Croatian

- Czech

- Danica

- Batavica

- African

- Esperanto

- Estonian

- Finnicum

- Frisian

- Gallician

- Georgian

- German

- Graeca

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- hebraice

- non

- Miao

- Hungarica

- Islandic

- igbo

- Indonesiaca

- hibernica

- Italian

- Iaponica

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandan

- Coreanica

- Kurdish

- Kyrgyz

- TB

- Latinus

- Latvian

- Lithuanian

- Luxemburgish

- macedonicum

- Malgashi

- Malay

- Malayalam

- Melitensis

- Maori

- Marathi

- Mongolica

- Myanmar

- Nepalica

- Norvegica

- Norvegica

- Occitan

- Pashto

- Persae

- Polonica

- Punjabi

- Romanian

- Samoanice

- Scotica Gaelic

- Serbian

- Anglicus

- Shona

- Sindhi

- Sinhala

- Moravica

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turci

- Ucraina

- Urdu

- Uighur

- Uzbek

- Vietnamica

- Cambrica

- Auxilium

- Yiddish

- Ioruba

- Zulu

Aug . 23, 2025 13:58 Ad album

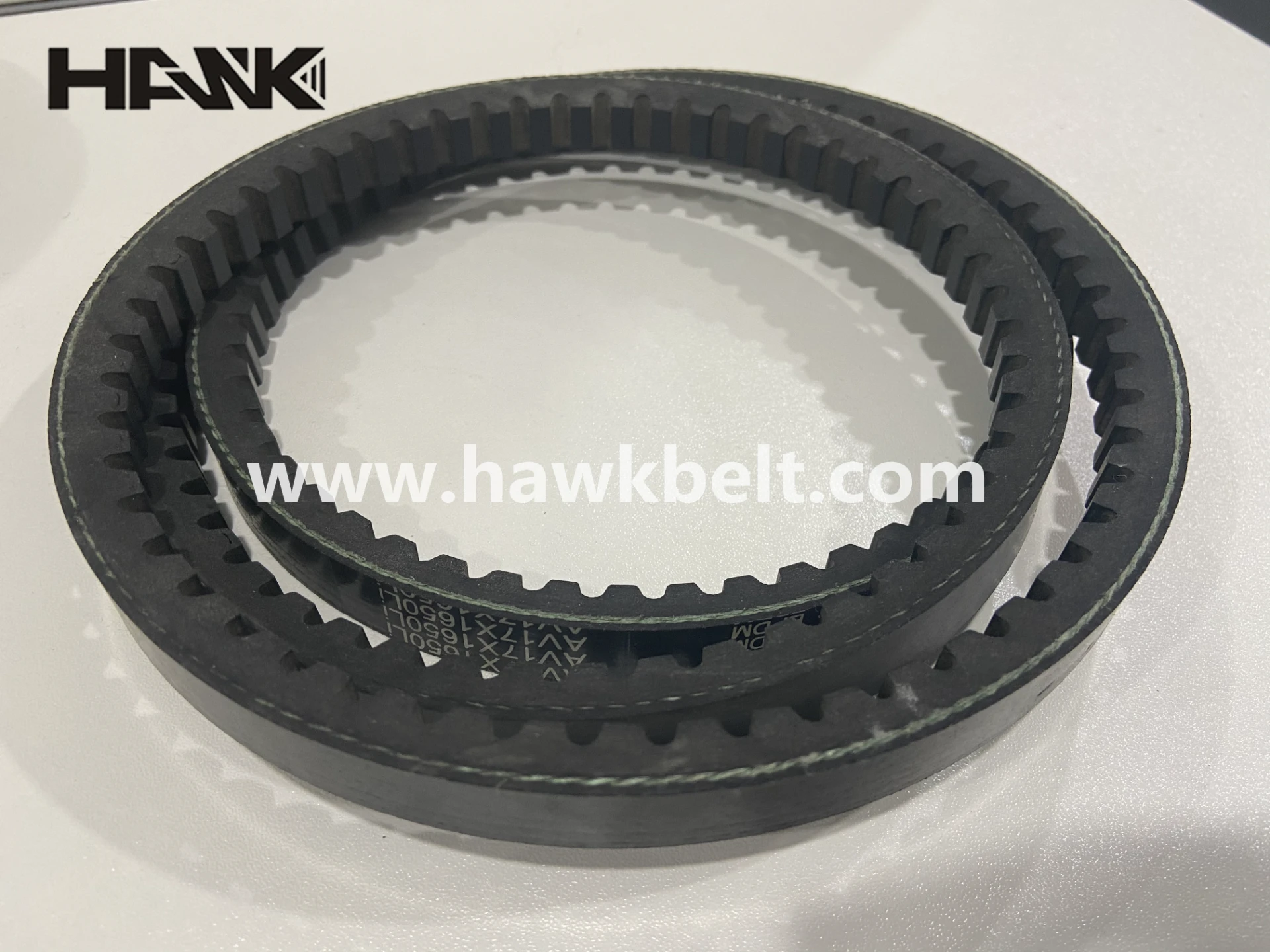

Toothed V Belt: Advanced Power Transmission for Modern Machinery

Toothed V Belt represents a significant advancement in power transmission technology, combining the trapezoidal profile of traditional V belts with precision-engineered teeth that mesh seamlessly with pulley grooves. This design innovation enhances torque transfer accuracy while maintaining the structural advantages of V-shaped cross-sections, making Toothed V Belt ideal for applications requiring synchronized motion and minimal slippage. Constructed with reinforced materials including cotton and synthetic fiber fabrics, these belts deliver exceptional performance across diverse industrial and automotive scenarios.

Toothed Drive Belts build upon the foundational design of Toothed V Belt by emphasizing synchronized power transfer in complex mechanical systems

Their evenly spaced teeth create positive engagement with corresponding pulley grooves, eliminating the slippage common in friction-driven belts and ensuring precise speed ratios between connected components. The incorporation of cotton fabrics in their core provides tensile strength and dimensional stability, while outer layers of synthetic fiber fabrics enhance resistance to abrasion and environmental factors. This combination makes Toothed Drive Belts indispensable in machinery where timing accuracy is critical, from conveyor systems to automotive camshaft drives.

Flat Belt vs V Belt comparisons highlight the unique advantages of Toothed V Belt in power transmission applications

While flat belt v belt rely on surface friction for power transfer and excel in high-speed, low-torque scenarios, Toothed V Belt offers superior torque capacity and positional accuracy due to its toothed engagement. The V-shaped profile of Toothed V Belt allows for efficient power transfer in confined spaces, while its toothed design adds synchronization capabilities that flat belts lack. This hybrid functionality makes Toothed V Belt a versatile choice, bridging the gap between the simplicity of flat belts and the precision of specialized timing belts.

Flat Belt Transmission systems, though effective for certain applications, face limitations that Toothed V Belt addresses through its innovative design

Traditional flat belt transmission relies on tension to generate friction, which can lead to energy loss and reduced efficiency over time, especially under varying loads. In contrast, Toothed V Belt’s positive tooth engagement minimizes energy loss by maintaining consistent contact with pulleys, even when subjected to fluctuating torque demands. This efficiency advantage, combined with Toothed V Belt’s compact profile, makes it a preferred alternative in modern machinery seeking to optimize both performance and space utilization.

Toothed Belt and Pulley assemblies form the core of synchronized power transmission systems, leveraging the precision of Toothed V Belt to achieve exact motion control

The pulley’s toothed profile is engineered to match the tooth spacing of the belt, creating a harmonious interface that distributes loads evenly across contact surfaces and reduces wear on both components. The flexibility of Toothed V Belt, enhanced by its cotton and synthetic fiber fabric construction, allows it to adapt to pulley misalignments within acceptable limits while maintaining consistent engagement. This synergy between Toothed Belt and Pulley ensures reliable operation in high-cycle applications, from industrial robots to printing presses.

Toothed V Belt exhibits exceptional material properties that contribute to its durability and performance longevity

Its core structure, reinforced with cotton fabrics, provides excellent flexibility that allows for small-diameter pulley operation without excessive stress. Outer layers composed of synthetic fiber fabrics enhance resistance to heat, withstanding continuous operating temperatures up to 120°C, while specialized rubber compounds deliver superior oil resistance when exposed to lubricants and hydraulic fluids. These combined attributes—flexibility, heat resistance, oil resistance, and wear resistance—make Toothed V Belt suitable for harsh environments where traditional belts would degrade rapidly.

In summary, Toothed V Belt stands as a versatile and reliable power transmission solution that merges precision engineering with durable materials. Toothed Drive Belts extend this technology to synchronized applications, while comparisons between Flat Belt vs V Belt highlight its efficiency advantages. Flat Belt Transmission systems benefit from its superior torque transfer capabilities, and Toothed Belt and Pulley assemblies demonstrate its precision in motion control. With core materials including cotton and synthetic fiber fabrics providing strength, flexibility, and resistance to heat, oil, and wear, Toothed V Belt continues to set new standards in power transmission technology, ensuring optimal performance across a wide range of industrial and automotive applications for years to come.

Toothed Drive Belts FAQs

1. What are the key performance advantages of toothed drive belts?

Toothed drive belts are engineered with exceptional flexibility, heat resistance, oil resistance, and abrasion resistance. This unique combination of properties is largely achieved through the use of specialized cord materials like cotton and synthetic fabric in their construction. This allows them to maintain precise synchronization and efficient power transmission in demanding environments where other belts might fail.

2. How does the material composition of a toothed drive belt contribute to its durability?

The integration of materials such as cotton and synthetic fabric within the belt's core provides a critical balance of strength and flexibility. These fabrics are impregnated with robust compounds that enhance their innate resistance to heat, oil, and wear. This construction ensures the toothed drive belt can withstand constant meshing with pulley teeth and exposure to harsh conditions without stretching or degrading.

3. In what types of applications are the properties of toothed drive belts most critical?

The superior properties of toothed drive belts, including their flexibility and resistance to heat, oil, and abrasion, are indispensable in precision applications. These include timing systems in automotive engines, high-speed packaging machinery, and CNC equipment. The use of durable materials like synthetic fabric ensures reliable performance where slippage or failure would lead to significant operational issues.

4. Why is flexibility such an important characteristic for a toothed drive belt?

The exceptional flexibility of a toothed drive belt allows it to smoothly engage and disengage from the teeth of a pulley while maintaining a constant pitch. This flexibility, provided by the underlying cotton or synthetic fabric cord, minimizes stress and heat buildup during operation. It enables the belt to run efficiently on smaller diameter pulleys and in compact drive designs, all while preserving its structural integrity.

5. How does the construction of a toothed drive belt protect it from operational hazards?

The belt is designed as a multi-component system where a durable backing and tensile cord, often made from synthetic fabric, are bonded to a precision-molded tooth profile. This construction creates a barrier that protects the critical load-bearing cords from direct exposure to oils, high temperatures, and abrasive debris. The result is a toothed drive belt that delivers extended service life and consistent performance.

-

V Belt Motorcycle: Essential Power Transmission in Two-Wheeled Vehicles

NewsAug.23,2025

-

Vehicle Timing Belt: Precision Engineering in Automotive Power Transmission

NewsAug.23,2025

-

V Drive Belts: Essential Power Transmission Solutions for Vehicles

NewsAug.23,2025

-

Automotive Belt Systems: Key Components for Power Transmission

NewsAug.23,2025

-

Automotive Belts: Critical Drive Components for Vehicle Performance

NewsAug.23,2025

-

Toothed V Belt: Advanced Power Transmission for Modern Machinery

NewsAug.23,2025