- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Dec . 05, 2024 15:22 Back to list

rubber ribbed belt

The Versatility and Importance of Rubber Ribbed Belts in Modern Machinery

Rubber ribbed belts, also known as serpentine belts or ribbed drive belts, play a crucial role in a wide array of machinery and automotive applications. These belts are designed with longitudinal grooves that enhance their grip and allow them to efficiently transfer power between various components. Their unique construction and material properties enable them to handle high levels of stress while maintaining flexibility and resilience, making them an indispensable part of modern engineering.

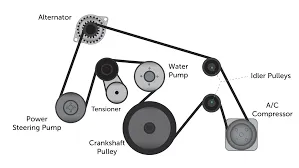

One of the primary applications of rubber ribbed belts is in automotive engines. Most modern vehicles utilize these belts to drive essential components, such as the alternator, power steering pump, water pump, and air conditioning compressor. The design of ribbed belts allows them to wrap around multiple pulleys, which provides a compact and efficient means of power transmission. This configuration not only optimizes space within the engine bay but also enhances the overall performance of the vehicle by reducing weight and minimizing energy loss.

The rubber used in these belts is typically a high-quality synthetic material designed to withstand various environmental factors, including extreme temperatures, humidity, and oil exposure. This durability ensures that rubber ribbed belts can operate reliably over extended periods, reducing the need for frequent replacements. Furthermore, the ribbed design increases the contact area with the pulleys, which enhances grip and power transfer. This means that even in high-torque situations, the chances of slippage are minimized, contributing to the longevity and efficiency of the drive system.

In addition to automotive applications, rubber ribbed belts are extensively used in industrial machinery, including conveyor systems, packaging equipment, and agricultural machinery. In these contexts, the ribbed belt’s ability to transmit force effectively while minimizing vibrations and noise makes it a preferred choice. For instance, in a conveyor system, the belt’s grip ensures that heavy loads are moved smoothly and without interruption. This reliability is vital in manufacturing processes where downtime can lead to significant financial losses.

rubber ribbed belt

Moreover, the design of rubber ribbed belts also allows for easy installation and maintenance. Many belts come with markings that indicate wear patterns, making it simpler for technicians to identify when a replacement is needed. Additionally, advancements in belt technology have led to the development of noise-reduction features, which further enhances the user experience in both automotive and industrial settings.

Another notable benefit of rubber ribbed belts is their adaptability. Manufacturers can produce these belts in various sizes and specifications to meet the specific needs of different machines. Whether it's a small gardening equipment engine or a large industrial conveyor, rubber ribbed belts can be tailored to fit. This customization plays a vital role in ensuring optimal performance across various applications, highlighting the versatility of this essential component.

Despite their many advantages, it is crucial for users to be aware of proper maintenance practices to ensure the longevity of rubber ribbed belts. Regular inspections for signs of wear, such as cracking or fraying, should be conducted. Furthermore, checking the alignment of pulleys can prevent excessive stress on the belt, extending its useful life.

In conclusion, rubber ribbed belts are a vital component in both automotive and industrial machinery, providing efficiency, reliability, and versatility. Their design facilitates effective power transfer while mitigating the risks of slippage and wear. As technology continues to advance, we can anticipate further improvements in the materials and designs of these belts, ensuring their place as a cornerstone of modern mechanical engineering. Whether on the road or in a factory, rubber ribbed belts are indeed indispensable to the smooth operation of countless machines.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025