- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

11월 . 17, 2024 21:44 Back to list

V Ribbed Belt Pulley Options and Benefits for Efficient Power Transmission Systems

Understanding V Ribbed Belt Pulleys A Comprehensive Overview

V ribbed belt pulleys, often referred to as serpentine pulleys, are integral components in the drive systems of various machinery, particularly in automotive applications. These components play a vital role in transferring power from the engine to different auxiliary systems, including the alternator, power steering pump, water pump, and air conditioning compressor. The design and functionality of V ribbed belts and their associated pulleys have a significant impact on the overall efficiency and performance of a vehicle or machinery.

What Are V Ribbed Belts and Pulleys?

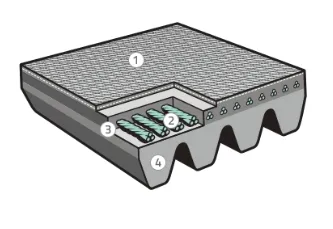

A V ribbed belt is an advanced type of belt that features a series of grooves running along its length. These grooves fit into corresponding ridges on the pulleys, allowing for better grip and reduced slippage compared to traditional flat or V-belts. The design of the V ribbed belt helps to distribute the load evenly across its surface, enhancing its durability and performance under various operational conditions.

The accompanying V ribbed belt pulleys are specially designed to accommodate these belts. They typically feature a multi-groove system which aligns perfectly with the ribs of the belt. This congruence ensures a tight fit that maximizes the contact surface area, thus improving the efficiency of power transmission.

Benefits of V Ribbed Belt Pulleys

2. Reduced Noise and Vibration Compared to traditional belts, V ribbed belts generate less noise and vibration during operation. This contributes to a smoother running system and increased comfort for users, particularly in vehicles.

v ribbed belt pulley

3. Space Efficiency The compact nature of V ribbed belts and pulleys makes them suitable for use in tight spaces. This is particularly advantageous in modern vehicles where space is often at a premium.

4. Extended Service Life The materials and design used in V ribbed belts and pulleys are engineered to withstand high levels of stress and wear, resulting in a longer service life compared to conventional systems.

5. Ease of Installation and Maintenance V ribbed belt systems are generally easier to install and maintain. The design allows for simple alignment, and the belts can often be replaced with minimal downtime.

Applications Beyond Automotive

While V ribbed belt pulleys are predominantly found in the automotive industry, their applications extend to various fields, including industrial machinery, HVAC systems, and agricultural equipment. These pulleys help in the smooth operation of motors, pumps, and conveyors, proving that the versatility of V ribbed belts stretches well beyond cars.

Conclusion

V ribbed belt pulleys are crucial elements that contribute to the efficiency and functionality of numerous mechanical systems. Their unique design offers several advantages over traditional belt systems, including improved power transmission, reduced noise, and enhanced durability. As technology continues to evolve, the role of V ribbed belts and their associated pulleys will likely expand further, making them indispensable in the realm of mechanical engineering and automotive design. Whether in vehicles or industrial machinery, understanding the importance of these components can lead to better maintenance practices and more efficient system performance.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025