- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

11월 . 13, 2024 01:29 Back to list

synchroflex belt

Understanding Synchroflex Belts A Key Component in Mechanical Systems

In the realm of mechanical engineering, efficiency and precision are paramount. One critical component that plays a vital role in ensuring these qualities is the synchroflex belt, commonly used in various applications ranging from automotive engines to industrial machinery. This article delves into the features, advantages, and applications of synchroflex belts and their significance in modern engineering.

What is a Synchroflex Belt?

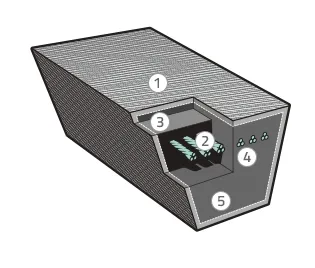

A synchroflex belt is a type of synchronous belt characterized by its toothed or ribbed design, offering a high degree of precision and reliability in power transmission. The belt works in conjunction with pulleys, and the teeth on the belt mesh perfectly with the grooves on the pulleys, ensuring that there is no slip between them. This synchronous action means that the belt’s movement is directly correlated with the rotation of the pulley, providing accurate timing and movement.

Features and Advantages

One of the most notable features of synchroflex belts is their ability to operate quietly and efficiently

. Unlike traditional V-belts, which may slip or wear out over time, synchroflex belts maintain a constant speed due to the positive engagement of the teeth. This characteristic leads to less energy wastage and improved overall efficiency of the mechanical system.Moreover, synchroflex belts are designed to handle varying loads and speeds, making them versatile for different applications. They are typically made from durable materials such as neoprene, polyurethane, or rubber, which enhance their longevity and resistance to wear and tear. These belts are also lighter than their counterparts, contributing to less overall weight in machinery and allowing for faster acceleration and deceleration.

synchroflex belt

Another significant advantage is their low maintenance requirement. Since synchroflex belts do not need lubrication and show minimal wear from friction, they can operate for extended periods without the need for frequent replacement or servicing. This translates into lower operational costs and increased productivity for industries.

Applications of Synchroflex Belts

Synchroflex belts are prevalent in various sectors, including automotive, industrial machinery, and even robotics. In automotive applications, they play a crucial role in the timing mechanisms of engines, ensuring that valves and pistons operate in perfect synchronization.

In industrial settings, these belts are often used in conveyor systems, where precise timing is essential for material handling. Additionally, they find applications in printing machinery, food processing equipment, and many automated systems requiring accurate and efficient power transmission.

Conclusion

Synchroflex belts represent a vital innovation in power transmission technology, addressing the need for efficiency, precision, and reliability. Their unique design, coupled with the advantages they bring to various applications, makes them an indispensable tool in modern mechanical systems. As industries continue to evolve and demand greater efficiency, the importance of synchroflex belts will only increase, solidifying their place in the future of engineering and manufacturing processes. In a world where precision matters, synchroflex belts offer a reliable solution that engineers can trust.

-

Variable Belt Drive AI Optimized for Efficiency

NewsAug.05,2025

-

Durable Diesel Engine Belt with GPT-4-Turbo AI Tech | Precision Fit

NewsAug.04,2025

-

High-Quality Tensioner Belt Pulley - Durable & Efficient

NewsAug.03,2025

-

Premium Timing Belt Factory | AI-Optimized Solutions

NewsAug.02,2025

-

Premium Custom V Belts Enhanced with GPT-4 Turbo AI

NewsAug.01,2025

-

Car Serpentine Belt: AI-Optimized Performance with GPT-4-Turbo

NewsJul.31,2025