- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

6월 . 16, 2024 13:31 Back to list

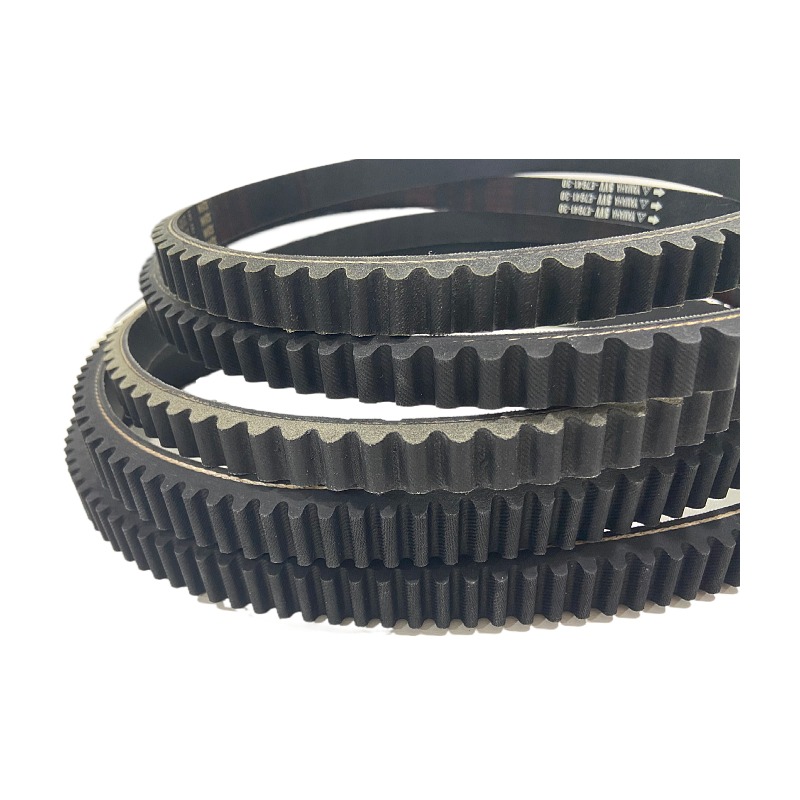

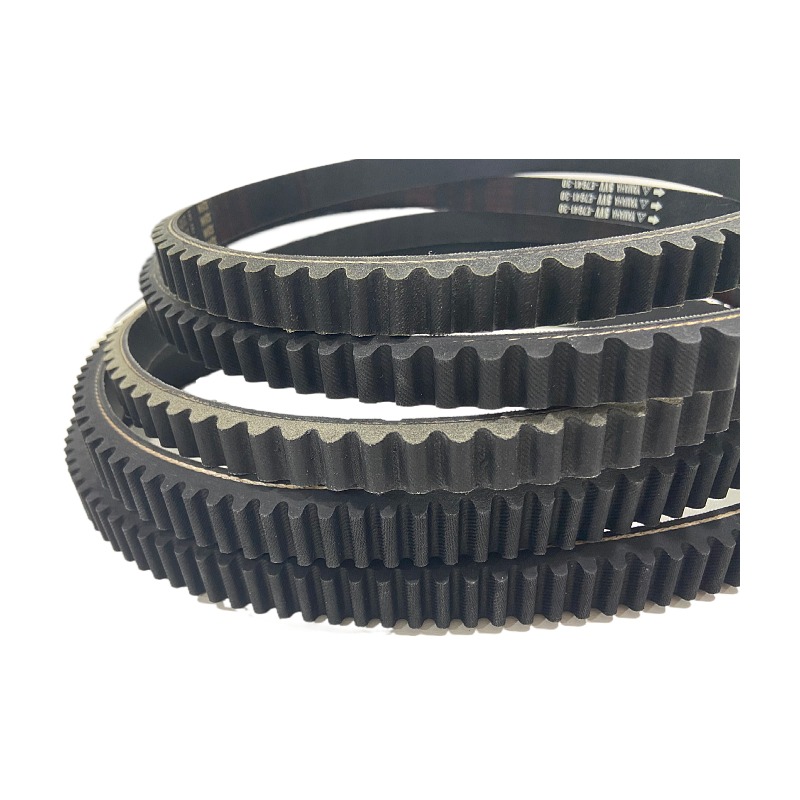

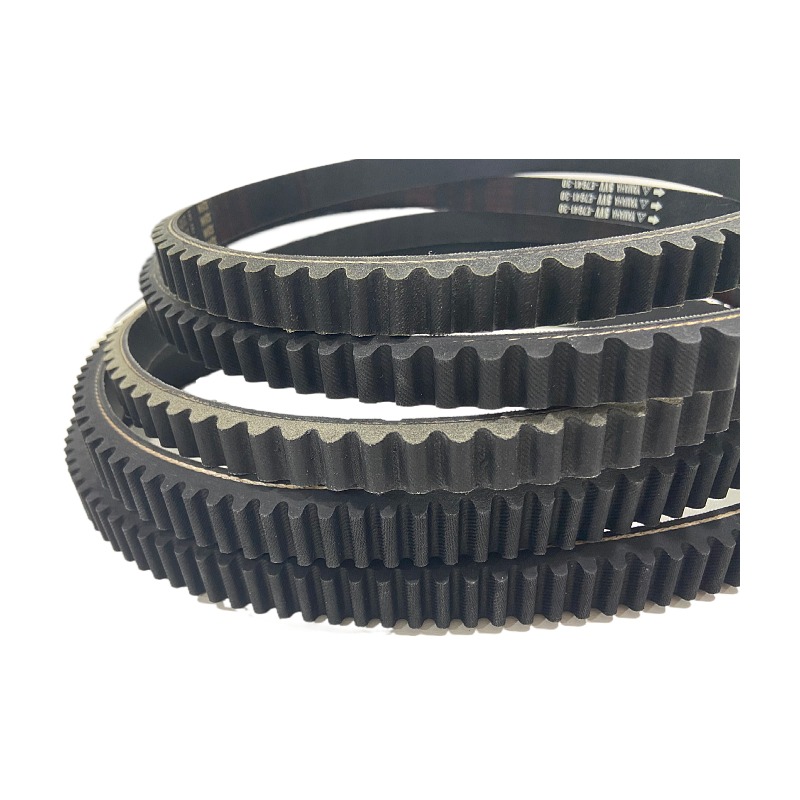

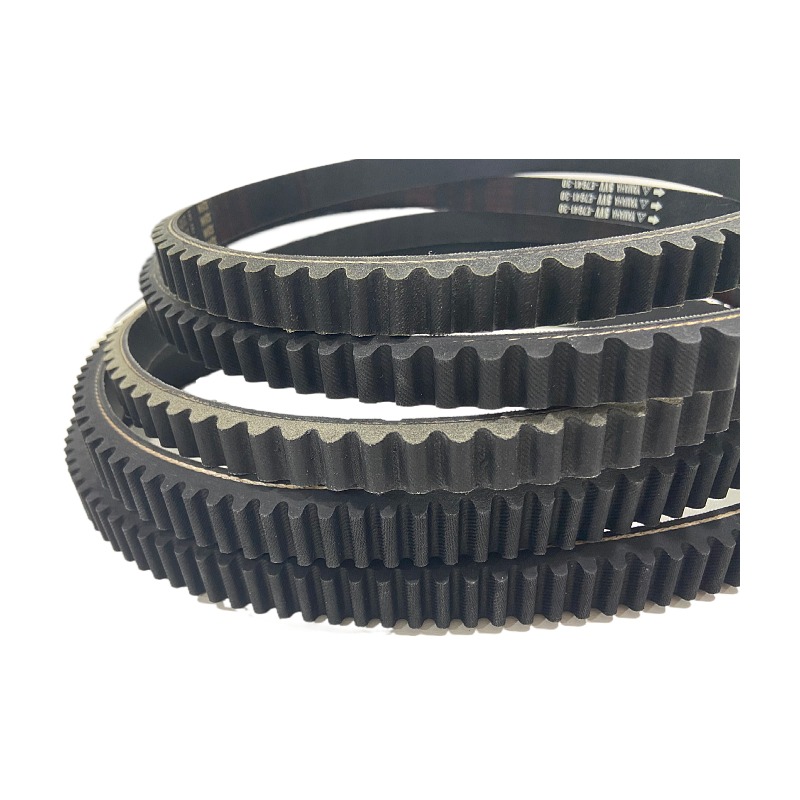

Stepper motor belt drive system.

Harnessing the Power of Stepper Motor Belts in Precision Engineering

In the realm of precision engineering and machinery, stepper motor belts emerge as silent heroes, orchestrating intricate movements with unparalleled accuracy. The marriage of stepper motors and belts is a testament to innovation, where simplicity meets efficiency.

A stepper motor belt system is an assembly that translates the precise rotational movement of a stepper motor into linear motion through a belt and pulley mechanism. This setup allows for highly controlled and finely tuned movements, making it ideal for applications requiring exact positioning, such as 3D printing, CNC machines, and robotics.

The heart of this system beats in the stepper motor, an electric motor that divides a full rotation into a series of individual steps. Each step corresponds to a specific angular displacement, providing exceptional control over the motor's position and speed. When paired with a belt, these steps can be converted into precise linear movements.

The belt itself is a robust yet flexible component, typically made from high-strength materials like reinforced rubber or polyurethane. It interfaces with the stepper motor via a toothed pulley, which engages with the belt's teeth to transmit motion without slippage. This direct drive method reduces backlash, the play or lost motion in mechanical systems, ensuring that each command results in a predictable and accurate action.

One of the most significant advantages of stepper motor belt systems is their repeatability. Once calibrated, these systems can consistently return to the same positions with minimal deviation. They also boast high torque at low speeds, making them suitable for tasks that require slow and steady progress with heavy loads They also boast high torque at low speeds, making them suitable for tasks that require slow and steady progress with heavy loads They also boast high torque at low speeds, making them suitable for tasks that require slow and steady progress with heavy loads They also boast high torque at low speeds, making them suitable for tasks that require slow and steady progress with heavy loads

They also boast high torque at low speeds, making them suitable for tasks that require slow and steady progress with heavy loads They also boast high torque at low speeds, making them suitable for tasks that require slow and steady progress with heavy loads stepper motor belt.

However, the efficacy of stepper motor belts extends beyond mere physical attributes. Their digital nature means they can be easily integrated into computer-controlled systems, offering a seamless interface between the digital and mechanical worlds. This digital control opens up possibilities for programming complex movements and synchronizing multiple axes in machines like CNC routers.

Despite their many benefits, stepper motor belt systems are not without challenges. Proper tensioning of the belt is crucial for optimal performance; too much or too little can lead to slippage or excessive wear. Additionally, while stepper motors are known for their precision, they can suffer from problems such as resonance at certain speeds, requiring careful tuning and control algorithms to mitigate.

In conclusion, the stepper motor belt system is a marvel of modern engineering. Its ability to transform the discrete rotational motion of a stepper motor into smooth and precise linear action has revolutionized industries. From the microscopic layers of a 3D-printed object to the precise cuts of a CNC machine, stepper motor belts have become essential components in achieving technical mastery over mechanical motion. As technology continues to advance, so too will the applications and refinements of stepper motor belt systems, further solidifying their role in the ever-evolving landscape of precision engineering.

stepper motor belt.

However, the efficacy of stepper motor belts extends beyond mere physical attributes. Their digital nature means they can be easily integrated into computer-controlled systems, offering a seamless interface between the digital and mechanical worlds. This digital control opens up possibilities for programming complex movements and synchronizing multiple axes in machines like CNC routers.

Despite their many benefits, stepper motor belt systems are not without challenges. Proper tensioning of the belt is crucial for optimal performance; too much or too little can lead to slippage or excessive wear. Additionally, while stepper motors are known for their precision, they can suffer from problems such as resonance at certain speeds, requiring careful tuning and control algorithms to mitigate.

In conclusion, the stepper motor belt system is a marvel of modern engineering. Its ability to transform the discrete rotational motion of a stepper motor into smooth and precise linear action has revolutionized industries. From the microscopic layers of a 3D-printed object to the precise cuts of a CNC machine, stepper motor belts have become essential components in achieving technical mastery over mechanical motion. As technology continues to advance, so too will the applications and refinements of stepper motor belt systems, further solidifying their role in the ever-evolving landscape of precision engineering.

They also boast high torque at low speeds, making them suitable for tasks that require slow and steady progress with heavy loads They also boast high torque at low speeds, making them suitable for tasks that require slow and steady progress with heavy loads

They also boast high torque at low speeds, making them suitable for tasks that require slow and steady progress with heavy loads They also boast high torque at low speeds, making them suitable for tasks that require slow and steady progress with heavy loads stepper motor belt.

However, the efficacy of stepper motor belts extends beyond mere physical attributes. Their digital nature means they can be easily integrated into computer-controlled systems, offering a seamless interface between the digital and mechanical worlds. This digital control opens up possibilities for programming complex movements and synchronizing multiple axes in machines like CNC routers.

Despite their many benefits, stepper motor belt systems are not without challenges. Proper tensioning of the belt is crucial for optimal performance; too much or too little can lead to slippage or excessive wear. Additionally, while stepper motors are known for their precision, they can suffer from problems such as resonance at certain speeds, requiring careful tuning and control algorithms to mitigate.

In conclusion, the stepper motor belt system is a marvel of modern engineering. Its ability to transform the discrete rotational motion of a stepper motor into smooth and precise linear action has revolutionized industries. From the microscopic layers of a 3D-printed object to the precise cuts of a CNC machine, stepper motor belts have become essential components in achieving technical mastery over mechanical motion. As technology continues to advance, so too will the applications and refinements of stepper motor belt systems, further solidifying their role in the ever-evolving landscape of precision engineering.

stepper motor belt.

However, the efficacy of stepper motor belts extends beyond mere physical attributes. Their digital nature means they can be easily integrated into computer-controlled systems, offering a seamless interface between the digital and mechanical worlds. This digital control opens up possibilities for programming complex movements and synchronizing multiple axes in machines like CNC routers.

Despite their many benefits, stepper motor belt systems are not without challenges. Proper tensioning of the belt is crucial for optimal performance; too much or too little can lead to slippage or excessive wear. Additionally, while stepper motors are known for their precision, they can suffer from problems such as resonance at certain speeds, requiring careful tuning and control algorithms to mitigate.

In conclusion, the stepper motor belt system is a marvel of modern engineering. Its ability to transform the discrete rotational motion of a stepper motor into smooth and precise linear action has revolutionized industries. From the microscopic layers of a 3D-printed object to the precise cuts of a CNC machine, stepper motor belts have become essential components in achieving technical mastery over mechanical motion. As technology continues to advance, so too will the applications and refinements of stepper motor belt systems, further solidifying their role in the ever-evolving landscape of precision engineering. Share:

Latest news

-

High-Quality Tensioner Belt Pulley - Durable & Efficient

NewsAug.03,2025

-

Premium Timing Belt Factory | AI-Optimized Solutions

NewsAug.02,2025

-

Premium Custom V Belts Enhanced with GPT-4 Turbo AI

NewsAug.01,2025

-

Car Serpentine Belt: AI-Optimized Performance with GPT-4-Turbo

NewsJul.31,2025

-

Heat Joining Drive Belt | High-Durability Fusion Solution

NewsJul.31,2025

-

Timing Belt Video Guide: Selection, Design & Quality Insights

NewsJul.30,2025