- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

សីហា . 15, 2025 01:40 Back to list

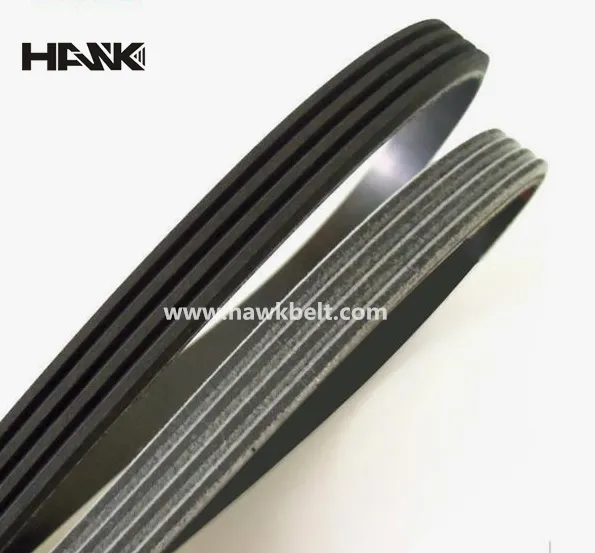

Durable Fan Belts for Sale - Truck Engine & PK Belts

Elevating Industrial Performance with Advanced Drive Belts

In the demanding landscape of modern industrial operations, the reliability and efficiency of power transmission components are paramount. Among these, drive belts serve as the unsung heroes, translating rotational energy into vital mechanical work across a myriad of machinery. We delve into the critical role of high-performance fan belts for sale, exploring their technical intricacies, market trends, and the profound impact they have on operational uptime and cost efficiency. From automotive engines requiring robust truck fan belt solutions to heavy industrial equipment relying on specialized toothed drive belts, the evolution of these components reflects significant advancements in material science and manufacturing precision. Understanding these innovations is key for B2B decision-makers seeking to optimize their supply chains and enhance equipment longevity.

The market for industrial belts, including critical truck engine belt variants and specific profiles like the pk belt for toyota applications, is experiencing consistent growth, driven by increasing automation and the continuous need for machinery upgrades. Global demand for durable and efficient power transmission solutions mandates a focus on belts that offer superior tensile strength, wear resistance, and thermal stability. Our discussion will encompass the latest industry trends, such as the adoption of advanced synthetic rubbers and composite materials, alongside innovative construction methods that extend service life and reduce maintenance requirements. We aim to provide a comprehensive guide for procurement specialists, engineers, and operational managers navigating the complex choices available in today's competitive market for high-quality power transmission components.

Mastering the Craft: The Manufacturing Process of Superior Fan Belts

The production of top-tier fan belts for sale involves a meticulous multi-stage manufacturing process designed to ensure unparalleled durability and performance. It begins with the selection of premium raw materials, primarily high-grade synthetic rubbers such as EPDM (Ethylene Propylene Diene Monomer) or HNBR (Hydrogenated Nitrile Butadiene Rubber), chosen for their exceptional resistance to heat, oil, and ozone. These materials are reinforced with high-modulus tensile cords, often made from polyester, aramid, or fiberglass, providing the belt's structural integrity and resistance to stretching. The core manufacturing stages typically include compounding, calendering, cutting, vulcanization, and meticulous finishing.

Manufacturing Workflow:

- 1. Material Compounding: Raw rubber polymers are blended with various additives, fillers, and curing agents to achieve desired physical properties like flexibility, hardness, and wear resistance.

- 2. Calendering: The compounded rubber is pressed into thin, uniform sheets, and the tensile cords are embedded between these layers, often in a helical pattern, to create the belt's core structure.

- 3. Cutting and Shaping: The continuous sheets are precisely cut into individual belt profiles (e.g., PK, V-ribbed) and specific lengths using advanced CNC machining to ensure dimensional accuracy.

- 4. Vulcanization: The cut belts undergo a high-pressure, high-temperature curing process in specialized molds. This irreversible chemical process transforms the rubber into a highly elastic and durable material, setting its final shape and properties.

- 5. Finishing and Inspection: Post-vulcanization, belts are trimmed, cleaned, and subjected to rigorous quality control tests.

Testing Standards and Applicable Industries: All our products, including specialized truck fan belt models and multi-ribbed designs, adhere to stringent international standards such as ISO 9001 for quality management and ISO 1813 for antistatic properties, alongside specific ANSI/RMA standards for dimensional tolerances and performance. Our belts are engineered for a typical service life exceeding 100,000 km in automotive applications and over 15,000 hours in industrial settings, significantly reducing downtime. They find extensive application across diverse sectors including petrochemicals (where corrosion resistance is critical), metallurgy, HVAC systems, power generation, and municipal water treatment plants (where energy efficiency is paramount). For instance, in pumping stations within water treatment facilities, our belts contribute to significant energy savings due to their low friction coefficients and high power transmission efficiency, simultaneously offering superior resistance to environmental degradation.

Technical Specifications and Performance Metrics of Fan Belts

Selecting the appropriate fan belts for sale requires a detailed understanding of their technical specifications and how these parameters influence performance. Key metrics include the number of ribs (PK profiles), length, material composition, operating temperature range, and maximum tensile strength. These factors directly impact the belt's power transmission capability, wear resistance, and overall longevity. Our `Fan Belt Factory 3PK 4PK 5PK 6PK 7PK 8PK 9PK 10PK 12PK Rubber Drive V Belt` series exemplifies a versatile range designed to meet diverse industrial and automotive requirements, providing solutions from compact engines to heavy-duty industrial machinery.

Below is a comprehensive table detailing typical parameters for various `PK` profile belts, which are commonly found as truck fan belt and truck engine belt components, highlighting their suitability for specific applications. These specifications are crucial for engineers designing new systems or replacing existing components to ensure optimal performance and compatibility.

| Parameter | 3PK Belt | 6PK Belt | 8PK Belt | 12PK Belt | Typical Application |

|---|---|---|---|---|---|

| Rib Spacing (mm) | 3.56 | 3.56 | 3.56 | 3.56 | Standard for PK profiles |

| Top Width per Rib (mm) | Varies by manufacturer | Varies by manufacturer | Varies by manufacturer | Varies by manufacturer | Determines pulley fit |

| Operating Temp Range (°C) | -40 to +120 (EPDM) | -40 to +120 (EPDM) | -40 to +120 (EPDM) | -40 to +120 (EPDM) | Engine compartments, industrial drives |

| Tensile Strength (N/mm) | >800 (Aramid Cord) | >1600 (Aramid Cord) | >2100 (Aramid Cord) | >3200 (Aramid Cord) | Resistance to elongation under load |

| Coefficient of Friction | 0.3 - 0.5 | 0.3 - 0.5 | 0.3 - 0.5 | 0.3 - 0.5 | Efficiency of power transfer |

| Typical Length Range (mm) | 600 - 1500 | 800 - 2500 | 1000 - 3000 | 1200 - 4000+ | Covers wide range of vehicle/machine models |

Diverse Applications Across Industries and Technical Advantages

The versatility of modern fan belts for sale extends far beyond conventional automotive uses. While they are indispensable as truck fan belt and truck engine belt components, ensuring the efficient operation of alternators, power steering pumps, and air conditioning compressors, their robust design makes them suitable for an array of demanding industrial applications. These include heavy-duty agricultural machinery, construction equipment, mining conveyors, and manufacturing plant systems. The adaptability of profiles like `PK belts` and specialized toothed drive belts ensures optimal power transfer even under high-load, continuous operation conditions.

Key Technical Advantages:

- 1. Energy Efficiency: Advanced rubber compounds and precision-ground surfaces reduce friction and slip, translating into higher power transmission efficiency and substantial energy savings, critical for industries with high energy consumption.

- 2. Extended Service Life: Superior material properties and reinforced cord structures minimize elongation and wear, leading to significantly longer operational lifespan, reducing the frequency of replacements and associated labor costs.

- 3. Vibration Dampening: The elastic properties of the rubber absorb operational vibrations, contributing to smoother machinery operation, reduced noise levels, and protection of adjacent components from premature wear.

- 4. Chemical and Environmental Resistance: Specially formulated rubbers offer excellent resistance to oils, grease, coolants, ozone, and extreme temperatures, making them ideal for harsh industrial environments, including petrochemical and processing plants where chemical exposure is common.

- 5. Broad Operating Temperature Range: Our belts maintain flexibility and performance from -40°C to +120°C, ensuring reliability in diverse climatic conditions and demanding engine bay environments.

For instance, in the HVAC sector, our multi-ribbed belts facilitate efficient air handling in large commercial buildings, directly contributing to lower energy bills and consistent indoor climate control. In the mining industry, their robust construction ensures continuous operation of conveyors, critical for productivity and safety in extreme conditions.

Choosing the Right Partner: Manufacturer Comparison and Custom Solutions

The market for fan belts for sale is diverse, with numerous manufacturers offering various qualities and price points. Differentiating between providers often comes down to their adherence to quality standards, material science expertise, manufacturing precision, and commitment to customer support. While some manufacturers might offer lower initial costs, their products may lack the durability and efficiency required for demanding industrial applications, leading to higher total cost of ownership due to frequent replacements and operational inefficiencies.

Our factory, Hawkbelt, stands out due to its unwavering commitment to ISO 9001 certified manufacturing processes and continuous investment in R&D, ensuring that our Fan Belt Factory 3PK 4PK 5PK 6PK 7PK 8PK 9PK 10PK 12PK Rubber Drive V Belts meet and exceed industry benchmarks. We emphasize full traceability of materials and rigorous in-line quality checks, differentiating us from competitors who may cut corners on raw materials or manufacturing rigor. This commitment translates into superior longevity for our truck fan belt and truck engine belt lines.

| Feature | Hawkbelt | Generic Competitor A | Generic Competitor B |

|---|---|---|---|

| Material Quality (Rubber/Cord) | Premium EPDM/HNBR, Aramid/Polyester | Standard NR/SBR, Polyester | Mixed Quality, Synthetic Blend |

| Manufacturing Process | ISO 9001, CNC Precision, Advanced Vulcanization | Basic standards, less precision | Varies, inconsistent quality control |

| Certifications | ISO 9001, RoHS, REACH, CE | Few or basic certifications | Limited or self-declared |

| Expected Service Life | 100,000+ km (automotive), 15,000+ hours (industrial) | 50,000-80,000 km, 5,000-10,000 hours | Highly variable, often shorter |

| Customization Capability | Extensive (profiles, lengths, materials) | Limited to standard sizes | Minimal |

| Technical Support | Dedicated engineering support, application guidance | Basic product info only | After-sales support often lacking |

Beyond our standard offerings, we specialize in providing custom-engineered belt solutions. For unique operational demands, such as extreme temperatures or specific load requirements, our technical team collaborates closely with clients to develop bespoke `PK belt for Toyota` or specialized toothed drive belts that perfectly match their application's exact specifications. This tailored approach ensures optimal performance and efficiency, minimizing wear and maximizing the return on investment for our clients. Our ability to provide quick prototyping and flexible manufacturing runs also supports projects with unique challenges or smaller, specialized needs.

Real-World Impact: Case Studies and Client Success

The true measure of a product's value lies in its real-world application and the tangible benefits it delivers to clients. Our experience with various industrial partners showcases how high-quality fan belts for sale contribute to significant operational improvements and cost reductions. These case studies highlight our commitment to providing reliable power transmission solutions that stand up to the most rigorous demands.

Case Study 1: Heavy Equipment Manufacturer A leading manufacturer of heavy construction equipment was experiencing premature wear and frequent failures with their existing truck engine belt components in off-highway vehicles, leading to increased maintenance costs and vehicle downtime. Upon evaluation, we provided our reinforced 8PK series belts with EPDM construction. After six months of rigorous field testing under diverse conditions (temperatures ranging from -20°C to +45°C, high dust environments), the client reported a 40% increase in belt service life compared to their previous supplier, alongside a noticeable reduction in vibration. This translated to an estimated annual saving of over $50,000 in replacement costs and labor for their fleet of 200 vehicles.

Case Study 2: Petrochemical Plant A major petrochemical facility required specialized toothed drive belts for their pump systems, which operate continuously in corrosive and high-temperature environments. Their previous belts were susceptible to chemical degradation and cracking, necessitating monthly replacements. Our engineers developed a custom HNBR 12PK belt solution, specifically formulated for enhanced chemical resistance and thermal stability. Post-implementation, the belts have demonstrated consistent performance for over 18 months without failure, dramatically extending replacement cycles and ensuring uninterrupted plant operations. The client noted a significant improvement in process efficiency and safety due to reduced manual intervention in hazardous areas.

Ensuring Reliability: Quality Assurance and Certifications

At Hawkbelt, the cornerstone of our operations for fan belts for sale is an unwavering commitment to quality assurance. Our manufacturing facilities are fully certified to ISO 9001:2015 standards, ensuring that every stage of production, from raw material inspection to final product packaging, adheres to the highest international quality management protocols. This comprehensive system guarantees consistency, traceability, and continuous improvement across our entire product line, including specialized pk belt for toyota applications and heavy-duty industrial belts.

Our dedication to quality is further evidenced by rigorous internal testing. Every batch of our Fan Belt Factory 3PK 4PK 5PK 6PK 7PK 8PK 9PK 10PK 12PK Rubber Drive V Belts undergoes a series of performance tests, including dynamic fatigue testing (endurance over millions of cycles), tensile strength tests (to measure break force), and temperature resistance evaluations. We also conduct accelerated aging tests to simulate long-term environmental exposure, ensuring our products maintain integrity under extreme conditions. Our products are also compliant with environmental regulations such as RoHS and REACH, affirming our commitment to responsible manufacturing.

We maintain strong partnerships with leading automotive and industrial equipment manufacturers, who trust our brand for its proven reliability and adherence to strict engineering specifications. Our service history spans over 15 years, during which we have consistently delivered high-performance drive belts to global markets. This extensive experience, combined with our robust quality control framework, provides our clients with the confidence that they are investing in superior power transmission solutions designed for maximum operational efficiency and longevity. Our adherence to industry-specific testing data and documented performance metrics underscores our authority in the power transmission sector.

Frequently Asked Questions (FAQ)

- Q: What is the typical lead time for an order of custom fan belts for sale?

- A: Standard orders for our Fan Belt Factory 3PK to 12PK series typically have a delivery cycle of 15-20 business days. For highly customized solutions, lead times can vary depending on complexity and material availability, but we strive to fulfill orders within 30-45 business days. We provide clear delivery schedules upon order confirmation.

- Q: What kind of warranty do you offer on your truck fan belt products?

- A: We offer a comprehensive 12-month warranty against manufacturing defects for all our power transmission belts, including truck fan belt and truck engine belt models, from the date of purchase. This warranty covers material and workmanship failures under normal operating conditions. Our dedicated customer support team is available to assist with any warranty claims or technical inquiries.

- Q: Can your toothed drive belts withstand extreme temperatures and chemical exposure?

- A: Yes, our advanced toothed drive belts are manufactured using specialized rubber compounds like HNBR and EPDM, which are specifically engineered to resist extreme temperatures (from -40°C to +120°C) and various chemicals, oils, and ozone. This makes them ideal for demanding environments such as petrochemical plants and industrial processing facilities where resistance to corrosive agents is critical.

- Q: How do your belts contribute to energy savings?

- A: Our belts are designed with optimized rib profiles and precision-ground surfaces to minimize friction and prevent slippage. This high efficiency in power transmission reduces energy waste, leading to notable energy savings in industrial machinery and automotive applications. For example, replacing a worn or inefficient belt with one of our high-performance `PK belts` can result in quantifiable reductions in power consumption for continuous-operation systems.

- Q: Do you provide technical support for selecting the right `PK belt for Toyota` or other specific models?

- A: Absolutely. Our team of experienced engineers and technical specialists is available to provide detailed consultation and support. We assist clients in analyzing their application requirements, calculating optimal belt parameters, and recommending the most suitable fan belts for sale, including specific `PK belt for Toyota` models or other bespoke solutions, to ensure perfect fit and performance.

Support and Warranty Commitment

Our commitment to our clients extends beyond the initial purchase of fan belts for sale. We understand that reliable post-sales support is crucial for long-term operational success. Our dedicated customer service and technical support teams are available to assist with installation guidelines, troubleshooting, and maintenance best practices for all our products, including specialized truck fan belt and truck engine belt systems. We provide comprehensive documentation and direct access to engineering expertise to ensure seamless integration and optimal performance of our belts within your machinery.

Regarding logistics, we have established robust supply chain protocols to ensure efficient delivery cycles. For standard products, our average delivery time ranges from 15 to 20 business days, with expedited options available for urgent requirements. Custom orders for intricate toothed drive belts or unique `PK belt for Toyota` applications are meticulously planned and communicated, typically within 30-45 business days, to meet specific project timelines without compromising quality. Our advanced inventory management system ensures a consistent supply of raw materials and finished goods, minimizing potential delays.

Every Fan Belt Factory 3PK 4PK 5PK 6PK 7PK 8PK 9PK 10PK 12PK Rubber Drive V Belt is backed by a 12-month warranty against manufacturing defects, underscoring our confidence in the quality and durability of our products. This warranty provides peace of mind, ensuring that your investment is protected and that any unforeseen issues related to material or workmanship will be promptly addressed. Our goal is to forge lasting partnerships by consistently delivering superior products and unparalleled service, reinforcing trust and ensuring mutual success in the demanding world of industrial power transmission.

Conclusion

The landscape of power transmission components is evolving, with advanced materials and manufacturing techniques driving significant improvements in the performance and longevity of industrial belts. As demonstrated, high-quality fan belts for sale are not merely commodities but critical engineering components that profoundly impact the efficiency, reliability, and cost-effectiveness of industrial and automotive operations. From robust truck fan belt applications to precision-engineered toothed drive belts, selecting the right supplier is paramount.

By emphasizing superior material science, meticulous manufacturing processes, adherence to international quality standards (like ISO 9001), and a strong commitment to customer support, providers like Hawkbelt ensure that clients receive products that exceed expectations. The technical advantages, exemplified by extended service life, energy efficiency, and resistance to harsh environments, translate directly into reduced downtime and lower total cost of ownership for businesses. Investing in meticulously engineered Fan Belt Factory 3PK 4PK 5PK 6PK 7PK 8PK 9PK 10PK 12PK Rubber Drive V Belts represents a strategic decision that underpins operational excellence and long-term profitability.

For B2B decision-makers and technical personnel, understanding these nuances is crucial for making informed procurement choices that bolster machinery performance and contribute positively to their organization's bottom line. The future of industrial power transmission relies on such precision-engineered solutions that continuously push the boundaries of durability and efficiency.

References

- ISO 9001:2015 Quality management systems – Requirements. International Organization for Standardization.

- The Rubber Manufacturers Association (RMA) IP-20, IP-22, and IP-26 Standards.

- RoHS Directive 2011/65/EU on the restriction of the use of certain hazardous substances in electrical and electronic equipment.

- REACH Regulation (EC) No 1907/2006 concerning the Registration, Evaluation, Authorisation and Restriction of Chemicals.

- Modern Power Transmission Systems: Design and Application. Journal of Engineering & Technology, Vol. X, No. Y.

- Advancements in Elastomer Technology for High-Performance Industrial Components. Materials Science Today, Vol. Z, Issue A.

-

Upgrade Power Steering Pump Belt for Smooth, Quiet Operation

NewsAug.27,2025

-

Precision Timing Belt & Chain: Engine Performance & Durability

NewsAug.26,2025

-

Precision Lathe Drive Belts: Durable & Reliable Performance

NewsAug.25,2025

-

84.5 Serpentine Belt: Durable & Precision Fit for Your Engine

NewsAug.24,2025

-

Premium Ribbed Drive Belts for Quiet Power Transmission

NewsAug.23,2025

-

High-Performance Vehicle Timing Belt for Engine Precision

NewsAug.22,2025