- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Қар . 20, 2024 10:23 Back to list

small toothed belts

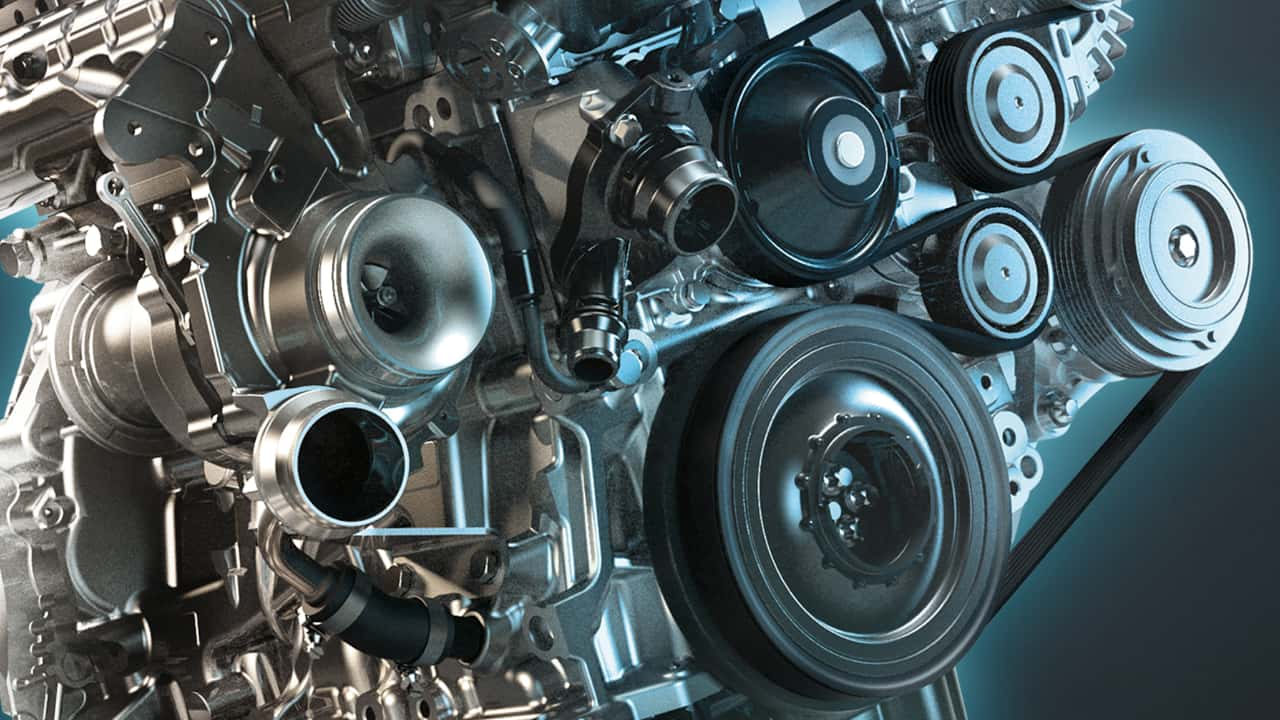

Understanding Small Toothed Belts The Key Component in Modern Machinery

Small toothed belts, commonly referred to as timing belts, play a crucial role in the functioning of various machines and vehicles. These belts, characterized by their toothed surfaces that interlock with corresponding gears or pulleys, ensure precise timing and synchronization of movements.

The Importance of Timing Belts

Timing belts are vital components in internal combustion engines and various mechanical applications. Their primary function is to link the crankshaft and camshaft, ensuring that the engine's valves open and close in perfect harmony with the movement of the pistons. This synchronization is essential for optimal engine performance, efficiency, and longevity.

In addition to automotive applications, small toothed belts are prevalent in machinery used across diverse industries, including manufacturing, robotics, and automation. These belts are engineered to handle high torque loads while maintaining accuracy, which is critical for processes that require precise positioning and timing.

Construction and Materials

Small toothed belts are typically made from high-strength materials such as rubber, polyurethane, or thermoplastic elastomers. The construction often includes reinforcement with fiberglass or aramid fibers, which enhances durability and minimizes stretch. The tooth design is meticulously crafted to provide maximum grip and reduce slippage, thereby ensuring efficient power transmission.

The size, shape, and tooth profile of these belts can vary significantly based on the specific application requirements. Commonly used tooth profiles include trapezoidal, round, and modified curvilinear shapes, each offering distinct advantages in terms of load capacity and noise reduction.

Advantages of Small Toothed Belts

1. Enhanced Performance Due to their precise design, small toothed belts provide excellent power transmission efficiency. This reduces energy loss and improves the overall performance of the machinery.

small toothed belts

2. Low Maintenance Unlike traditional V-belts, timing belts do not require lubrication, leading to low maintenance costs and minimal downtime. Most modern timing belts are designed to last for tens of thousands of miles or several years, depending on the application.

4. Noise Reduction The operation of small toothed belts is generally quieter than that of chains or gears, making them suitable for environments where noise reduction is a priority.

5. Versatility The adaptability of small toothed belts allows them to be used in a wide range of machinery, from small tools to large industrial machines, making them a versatile choice across industries.

Challenges and Considerations

Despite their advantages, small toothed belts are not without challenges. Overloading, improper installation, or lack of regular maintenance can lead to premature failure. Additionally, exposure to harsh environments, such as extreme temperatures or chemical hazards, may affect the lifespan of the belts.

To mitigate these concerns, it is critical to follow manufacturer guidelines regarding installation, maintenance, and operation. Regular inspections can help identify wear and tear, ensuring timely replacements and preventing potential failures.

Conclusion

Small toothed belts are indispensable components that contribute significantly to the efficiency and reliability of modern machinery and vehicles. Their precision, durability, and versatility make them a preferred choice in various applications, spanning from automotive systems to industrial automation. Understanding the mechanics and maintenance requirements of these belts can help users maximize their performance and extend their lifespan, ensuring smooth operations in critical processes. As technology continues to evolve, advancements in materials and design will likely enhance the capabilities of small toothed belts, further solidifying their role in the future of engineering and manufacturing.

-

Buy Serpentine Belt Online – Affordable Prices & Durable Quality

NewsJul.26,2025

-

High-Performance Metric Variable Speed Belts for Industrial Use

NewsJul.25,2025

-

High-Quality Endless Flat Drive Belt for Precision Power Transmission

NewsJul.24,2025

-

High-Performance Serpentine Belt for Car Engines – Durable & Reliable

NewsJul.23,2025

-

High Efficiency V Belt Drive with Double & Toothed Options for Industry

NewsJul.22,2025

-

Affordable Fan Belt Cost - Compare Prices & Save | Auto Parts Deals

NewsJul.22,2025