- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Қыр . 28, 2024 15:31 Back to list

Understanding the Basics and Benefits of Belt Conveyors in Material Handling

The Importance of Belt Conveyors in Modern Industry

Belt conveyors have become an integral part of industrial operations across various sectors, playing a crucial role in enhancing the efficiency and productivity of material handling processes. Originating in the late 18th century, belt conveyor systems have evolved over the years, becoming more sophisticated and versatile to meet the diverse needs of modern manufacturing, warehousing, and logistics.

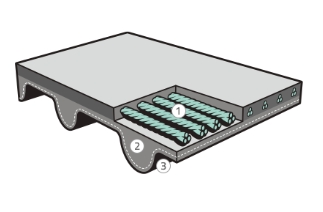

A belt conveyor consists of a continuous loop of material that moves from one point to another, utilizing a system of pulleys and rollers. The belt, usually made from sturdy materials such as rubber, fabric, or metal, is designed to withstand the weight and impact of the materials being transported. This simple yet effective design allows for the movement of a wide range of items, from bulk materials like sand and gravel to packaged goods and pallets.

One of the most significant advantages of using belt conveyors is their ability to transport large volumes of materials over long distances with minimal labor. In industries such as mining, agriculture, and manufacturing, belt conveyors can significantly reduce the time and effort required for material handling, allowing companies to focus their resources on core business operations. This efficiency not only leads to cost savings but also contributes to improved safety in the workplace. By minimizing manual handling, the risk of workplace injuries related to lifting and transporting heavy loads is substantially reduced.

belt conveyor

Furthermore, belt conveyors are highly customizable. Depending on the specific needs of a business, conveyors can be designed with varying widths, lengths, and configurations. They can be installed in straight lines, curves, or even inclined for elevation changes, making them suitable for a wide array of applications. Advanced technology has also paved the way for the integration of automated systems, such as sensors and control systems that monitor the performance of the conveyor and optimize its speed and operation.

Another key benefit of belt conveyors is their adaptability to various materials and environments. In industries such as food processing, where hygiene is paramount, manufacturers can use specialized belts that meet strict sanitation standards. In contrast, heavy-duty conveyors are designed to handle abrasive materials in mining operations, demonstrating the versatility of belt conveyor systems.

Environmental considerations are also becoming increasingly important in the design and operation of belt conveyors. Modern systems are often engineered to minimize energy consumption and are equipped with features to reduce noise pollution and maintain material integrity during transportation. For instance, the use of regenerative drives can capture excess energy generated during operation, further enhancing energy efficiency.

In conclusion, belt conveyors are essential components of contemporary industrial operations, providing significant advantages in efficiency, safety, and versatility. As industries continue to evolve and the demand for automation and improved productivity rises, the role of belt conveyors will only become more pronounced. Their ability to streamline operations and adapt to various requirements makes them indispensable in the quest for operational excellence. As technology progresses, we can expect even more innovations in belt conveyor design and functionality, ensuring they remain a cornerstone of material handling for years to come.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025