- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

მარ . 07, 2025 01:47 Back to list

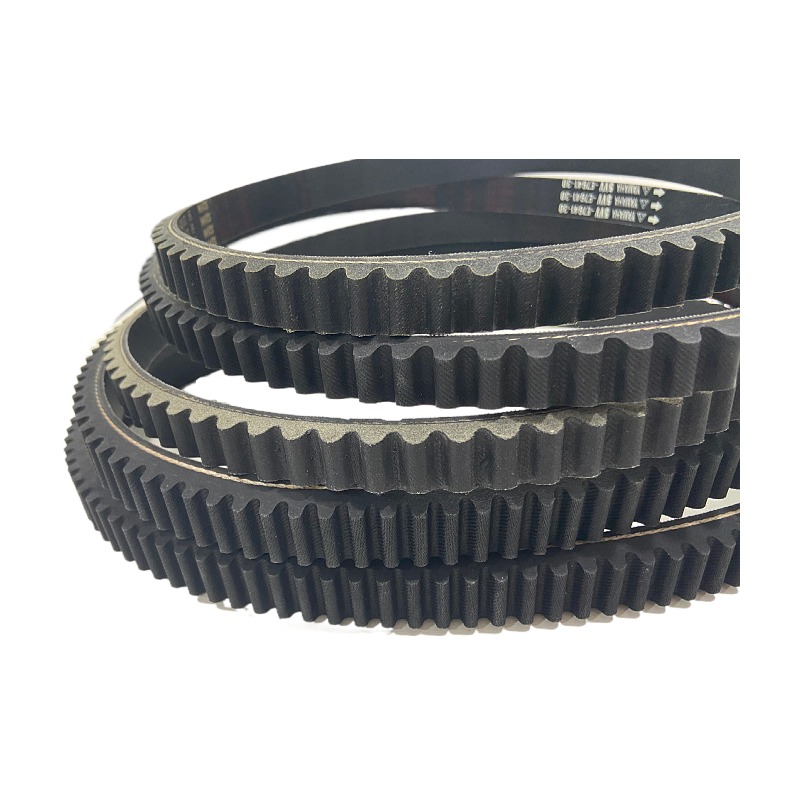

v belt pulley material

Selecting the right material for a V-belt pulley can significantly influence the performance, durability, and efficiency of equipment. Drawing on years of industry experience and technical expertise, this comprehensive guide will delve into the various materials available for V-belt pulleys, their properties, advantages, and applications to equip decision-makers with the knowledge they need to make informed choices.

Aluminum pulleys are the epitome of energy efficiency, primarily due to their lightweight nature. While they may not have the strength of steel or cast iron, their reduction in weight leads to less energy consumption, which is crucial for energy-efficient systems. Aluminum also offers excellent resistance to corrosion, courtesy of its natural oxide layer, making it suitable for environments with high humidity or exposure to chemicals. For applications where weight reduction is crucial—such as in automotive or aerospace industries—aluminum pulleys are the material of choice. Composite Materials The Future Frontier The quest for innovative solutions has led to the development of composite materials for V-belt pulleys. These materials combine fibers such as carbon or glass with resins to achieve specific mechanical properties. Composite pulleys offer a remarkable combination of strength, lightness, and resistance to environmental factors. They mark a significant advancement in material technology, especially for applications where traditional materials might fall short. Although they generally come with a higher initial cost, the long-term benefits in terms of performance and maintenance savings are substantial. Choosing the Right Material Deciding on the ideal material for a V-belt pulley ultimately hinges on a thorough understanding of the specific application's requirements—factor in load-bearing capacity, environmental conditions, weight limitations, and cost considerations. Industries are encouraged to consult with material scientists or mechanical engineers to leverage their expertise for informed decision-making. Additionally, relying on established brands and manufacturers with a track record of quality assurance and innovation further adds to the reliability and trustworthiness of the choice made. In conclusion, the advent of new materials and the continual refinement of existing ones offer a plethora of options that cater to varying industrial needs. With sustainability and efficiency becoming increasingly vital, the evolution of V-belt pulley materials is set to drive more innovation in industrial machinery design.

Aluminum pulleys are the epitome of energy efficiency, primarily due to their lightweight nature. While they may not have the strength of steel or cast iron, their reduction in weight leads to less energy consumption, which is crucial for energy-efficient systems. Aluminum also offers excellent resistance to corrosion, courtesy of its natural oxide layer, making it suitable for environments with high humidity or exposure to chemicals. For applications where weight reduction is crucial—such as in automotive or aerospace industries—aluminum pulleys are the material of choice. Composite Materials The Future Frontier The quest for innovative solutions has led to the development of composite materials for V-belt pulleys. These materials combine fibers such as carbon or glass with resins to achieve specific mechanical properties. Composite pulleys offer a remarkable combination of strength, lightness, and resistance to environmental factors. They mark a significant advancement in material technology, especially for applications where traditional materials might fall short. Although they generally come with a higher initial cost, the long-term benefits in terms of performance and maintenance savings are substantial. Choosing the Right Material Deciding on the ideal material for a V-belt pulley ultimately hinges on a thorough understanding of the specific application's requirements—factor in load-bearing capacity, environmental conditions, weight limitations, and cost considerations. Industries are encouraged to consult with material scientists or mechanical engineers to leverage their expertise for informed decision-making. Additionally, relying on established brands and manufacturers with a track record of quality assurance and innovation further adds to the reliability and trustworthiness of the choice made. In conclusion, the advent of new materials and the continual refinement of existing ones offer a plethora of options that cater to varying industrial needs. With sustainability and efficiency becoming increasingly vital, the evolution of V-belt pulley materials is set to drive more innovation in industrial machinery design.

Share:

Next:

Latest news

-

High-Quality Tensioner Belt Pulley - Durable & Efficient

NewsAug.03,2025

-

Premium Timing Belt Factory | AI-Optimized Solutions

NewsAug.02,2025

-

Premium Custom V Belts Enhanced with GPT-4 Turbo AI

NewsAug.01,2025

-

Car Serpentine Belt: AI-Optimized Performance with GPT-4-Turbo

NewsJul.31,2025

-

Heat Joining Drive Belt | High-Durability Fusion Solution

NewsJul.31,2025

-

Timing Belt Video Guide: Selection, Design & Quality Insights

NewsJul.30,2025