- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

იან . 17, 2025 04:30 Back to list

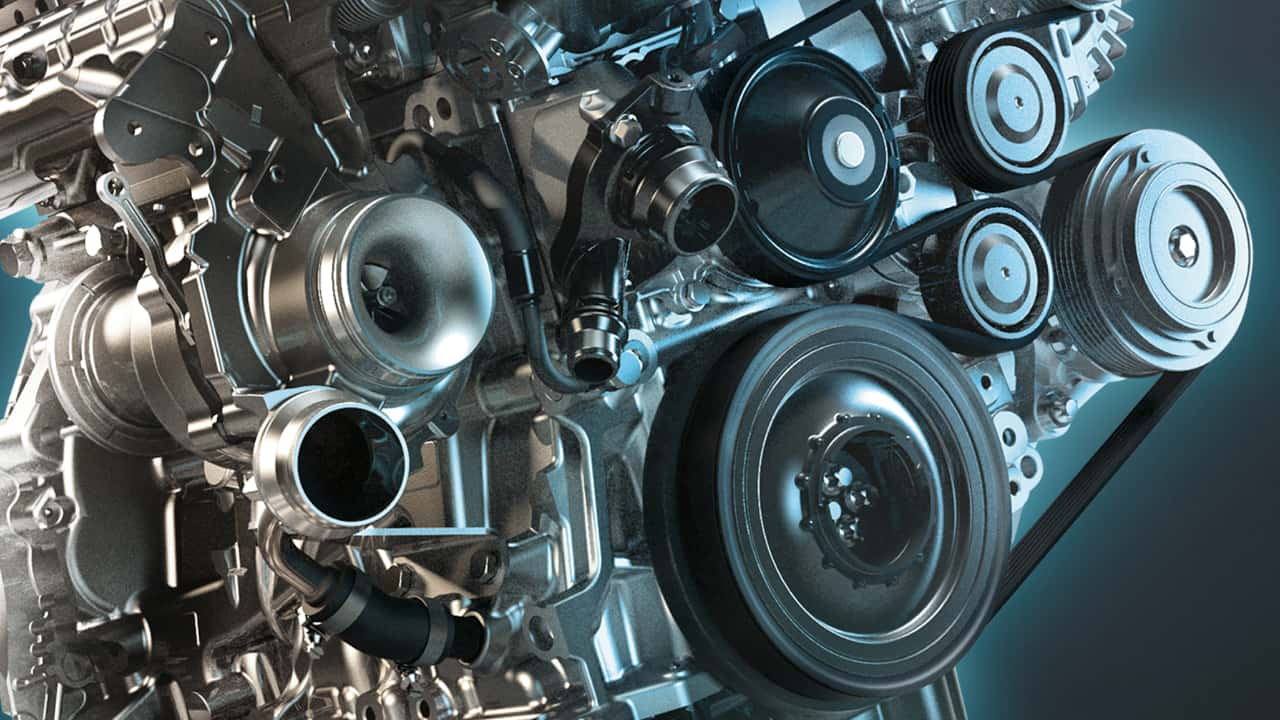

China Belt Factory 107YU22 114RPP17 Automotive Timing Belt Manufacturer

China's V-belts have steadily positioned themselves as indispensable components in the machinery and automotive industries across the globe. As a linchpin in power transmission, the V-belt is favored for its robustness, flexibility, and efficiency. When considering the purchase of V-belts from China, understanding their features, applications, and benefits can make a significant difference in optimizing the performance and durability of your machinery.

One cannot overlook the significant influence of technological advancements in the manufacture of V-belts. Chinese companies have incorporated aspects like computer-aided design and rapid prototyping to fine-tune belt specifications. This adoption of cutting-edge technology not only improves the preciseness but also ensures consistency across batches, further enhancing the trustworthiness of their products. Trust, a pivotal factor in global supply chains, is never a given but earned. Chinese V-belt manufacturers have cultivated trust by adhering to international quality standards like ISO and offering certifications like RoHS and REACH compliance. These credentials reassure customers of their commitment to environmental regulations and quality assurance. Transparent business processes, along with clear communication channels, further bolster faith in these enterprises. Moreover, the cost-effectiveness associated with China-made V-belts cannot be overseen. Competitive pricing arises from economic manufacturing processes and lower labor costs, allowing buyers to procure high-quality products without breaking the bank. However, it’s crucial to approach purchasing with a keen eye – selecting reputable suppliers over merely jumping for the lowest price can circumvent issues related to subpar quality. The future of V-belts also points toward sustainability. There is a progressive shift as manufacturers opt for environmentally friendly materials without compromising the belts’ structural integrity. This journey towards sustainability is accented by their perseverance in innovation, making Chinese V-belts an enduring choice worldwide. Engaging with seasoned experts, understanding manufacturing nuances, and leveraging strategic insights are vital for harnessing the full potential of China-made V-belts. As an end-user or distributor, these elements not only command excellence in operations but also build a robust network of reliability and efficiency.

One cannot overlook the significant influence of technological advancements in the manufacture of V-belts. Chinese companies have incorporated aspects like computer-aided design and rapid prototyping to fine-tune belt specifications. This adoption of cutting-edge technology not only improves the preciseness but also ensures consistency across batches, further enhancing the trustworthiness of their products. Trust, a pivotal factor in global supply chains, is never a given but earned. Chinese V-belt manufacturers have cultivated trust by adhering to international quality standards like ISO and offering certifications like RoHS and REACH compliance. These credentials reassure customers of their commitment to environmental regulations and quality assurance. Transparent business processes, along with clear communication channels, further bolster faith in these enterprises. Moreover, the cost-effectiveness associated with China-made V-belts cannot be overseen. Competitive pricing arises from economic manufacturing processes and lower labor costs, allowing buyers to procure high-quality products without breaking the bank. However, it’s crucial to approach purchasing with a keen eye – selecting reputable suppliers over merely jumping for the lowest price can circumvent issues related to subpar quality. The future of V-belts also points toward sustainability. There is a progressive shift as manufacturers opt for environmentally friendly materials without compromising the belts’ structural integrity. This journey towards sustainability is accented by their perseverance in innovation, making Chinese V-belts an enduring choice worldwide. Engaging with seasoned experts, understanding manufacturing nuances, and leveraging strategic insights are vital for harnessing the full potential of China-made V-belts. As an end-user or distributor, these elements not only command excellence in operations but also build a robust network of reliability and efficiency.

Share:

Latest news

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025