- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ნოე . 08, 2024 18:53 Back to list

belt drive

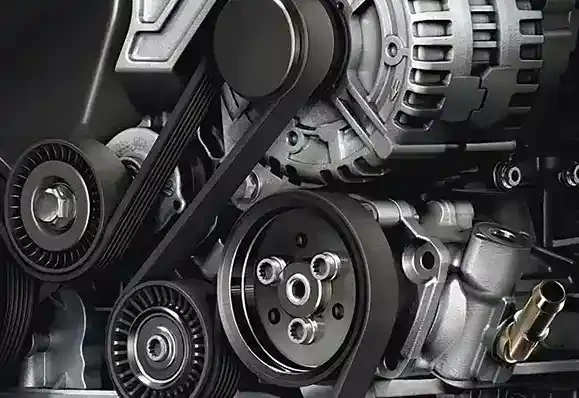

Understanding Belt Drives A Comprehensive Overview

Belt drives are a crucial part of mechanical systems, known for their efficiency and versatility in transferring power between shafts. They utilize flexible belts to transmit motion and force between two or more pulleys, making them indispensable in various applications—from industrial machines to vehicles. This article explores the working principle of belt drives, their types, advantages, and common applications.

Working Principle of Belt Drives

At its core, a belt drive consists of two or more pulleys connected by a belt made of flexible materials such as rubber or reinforced fabric. The driving pulley, which is attached to a power source like a motor, rotates and drives the belt. In turn, this motion is transferred to the driven pulley, which may be connected to another component like a gearbox or a conveyor. The interaction between the belt and the pulleys allows for efficient transfer of torque and rotational motion.

The effectiveness of a belt drive depends on several factors, including the type of belt used, the diameter of the pulleys, and the tension applied to the belt. Proper tension is vital, as it ensures adequate friction between the belt and the pulleys, preventing slippage and maximizing power transmission efficiency.

Types of Belt Drives

Belt drives can be categorized into several types based on their design and application

1. Flat Belts These are the simplest form of belt drives and are made from flat materials. They are commonly used in light-duty applications, such as in workshops and small machinery.

2. V-Belts Shaped like a “V,” these belts fit into corresponding grooves in the pulleys, providing better grip and reducing slippage. V-belts are widely used in automotive engines and industrial machinery due to their ability to handle higher loads.

3. Round Belts These belts are cylindrical and typically used in applications requiring flexibility and minimal friction, such as in conveyor systems.

4. Toothed Belts (Timing Belts) Featuring teeth that engage with corresponding grooves on the pulleys, toothed belts offer precise motion control, making them ideal for synchronous applications like camshaft drives in internal combustion engines.

Advantages of Belt Drives

Belt drives offer several distinct advantages, making them a preferred choice in various applications

belt drive

- High Efficiency Belt drives can achieve high transmission efficiency, often surpassing 95%. This is particularly beneficial in systems where power conservation is crucial.

- Flexibility The ability to transmit power over distances and through varying angles provides flexibility in machinery design. This adaptability makes belt drives suitable for a wide range of applications.

- Reduced Maintenance Unlike gear systems, belt drives have fewer moving parts, leading to reduced wear and tear and lower maintenance requirements. This can result in lower operational costs over time.

- Damping of Shock Loads Belts can absorb and dampen vibrations and shock loads, protecting connected components and extending their lifespan.

- Quieter Operation Belt drives produce less noise compared to other mechanical systems, making them suitable for environments where noise reduction is a priority.

Common Applications

Belt drives are ubiquitous across numerous industries. Some common applications include

- Automotive V-belts and timing belts are essential in vehicle engines for driving components such as alternators, water pumps, and camshafts.

- Industrial Machinery Belt drives are used in conveyor systems, textile machinery, and manufacturing equipment, facilitating efficient operation and movement of goods.

- Home Appliances Many household appliances, such as washing machines and vacuum cleaners, utilize belt drives to operate motors and various moving parts.

- Agricultural Equipment Belt systems are frequently found in tractors and other agricultural machinery, providing reliable power transfer for various functions.

Conclusion

In summary, belt drives are an integral component of modern mechanical systems, combining efficiency, versatility, and simplicity to facilitate power transmission across a multitude of applications. Understanding the various types, advantages, and uses of belt drives can help in making informed decisions about mechanical design and functionality, whether in industrial settings or everyday life. As technology continues to evolve, the role of belt drives will undoubtedly remain significant in driving innovation and efficiency across various industries.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025