- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Sep . 06, 2024 22:01 Back to list

V Belt 5kW / Poly V Belt Sizes - Comprehensive Guide

Understanding V-Belts and Poly V-Belt Sizes for 5kW Applications

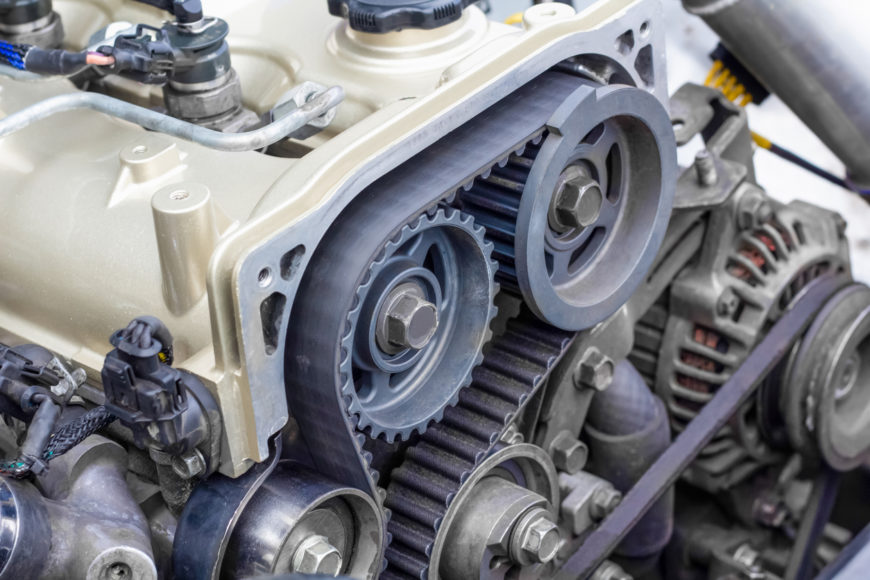

When it comes to mechanical power transmission systems, v-belts have long been recognized as an essential component due to their efficiency and versatility. The term v-belt refers to a type of belt with a distinctive V-shaped cross-section, which allows it to fit snugly in the grooved pulleys, thereby providing a reliable grip without slipping. This article focuses on the specific needs for 5kW applications and how poly v-belts vary in size to meet those requirements.

The Importance of V-Belts

V-belts are commonly used in various applications, including automotive systems, industrial machinery, and household appliances. Their design allows for a tight grip and high friction, which are crucial for transferring power effectively. They are particularly favored in applications where space-saving and efficient energy transfer are paramount. In a mechanical setup where a 5kW motor drives a load, choosing the right belt size ensures optimal performance and longevity.

Poly V-Belts An Innovative Alternative

Poly v-belts, also known as multi-rib belts, are a modern evolution of the traditional v-belt. Unlike standard v-belts, poly v-belts feature multiple small ribs running lengthwise along the belt's surface. This design increases the contact area with the pulleys, providing improved flexibility and the ability to handle higher loads. They are particularly useful in compact spaces where standard v-belts might not fit.

Poly v-belts are ideal for high-performance applications, as they can operate at higher speeds while maintaining stability. This makes them a suitable choice for 5kW systems, where reliability and efficiency are critical.

v belt 5kw\/poly v belt sizes

Sizing Considerations

Selecting the appropriate size for a v-belt or poly v-belt is essential for ensuring the longevity and effectiveness of the power transmission system. Typically, belt sizes are defined by their length, width, and profile design. For applications involving 5kW motors, it is important to consider not just the physical dimensions but also the specific load and operational conditions under which the belt will function.

1. Belt Length The length can determine how much tension is applied, affecting both grip and wear. Precise measurements are needed to ensure proper fit and function.

2. Belt Profile The profile, or cross-section, affects how the belt interacts with the pulley. For poly v-belts, a finely tuned profile improves the contact area, which is critical under high power loads.

3. Width and Rib Count In poly v-belts, width and rib count contribute significantly to load-handling capacity. More ribs often lead to better performance in terms of power transmission.

Conclusion

In conclusion, whether you are selecting a traditional v-belt or a poly v-belt for a 5kW application, understanding the sizing and specifications is crucial for optimal performance. With advancements in belt technology, poly v-belts offer superior options for many applications, especially where space is limited or where higher power loads are common. Through careful consideration of the belt’s size and profile, users can ensure efficient power transmission, reduced wear, and a longer operating life for their mechanical systems. As industries continue to evolve, the demand for reliable and efficient power transmission solutions will only grow, making the choice of v-belt sizes more critical than ever.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025