- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Aug . 20, 2024 11:31 Back to list

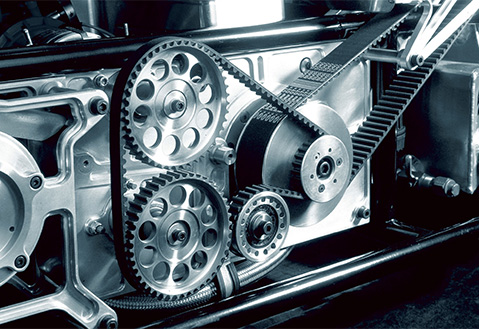

Understanding Automotive V-Belts and Their Importance in Vehicle Performance

Understanding Automotive V Belts A Crucial Component of Vehicle Performance

Automotive V belts, often referred to as serpentine belts in modern vehicles, play a crucial role in the overall performance and functionality of an engine. These belts are pivotal for driving various accessories such as the alternator, power steering pump, air conditioning compressor, and water pump. Understanding how V belts work, their types, maintenance, and the importance of timely replacements can help vehicle owners ensure optimal performance and longevity of their engines.

What are V Belts?

V belts are so named because of their trapezoidal cross-sectional shape, resembling the letter V. This design allows the belt to fit snugly into the pulleys it drives, providing a high level of friction and grip in order to transfer power effectively from the crankshaft to the various engine accessories. These belts are typically made from durable materials such as rubber, which may be reinforced with fibers for added strength and resistance to wear and tear.

Types of V Belts

There are several types of V belts used in automotive applications

. The most common include1. Classic V Belts These are the traditional belts, often used in older vehicle models. They are typically used for driving a single accessory.

2. Serpentine Belts A modern evolution of the classic V belt, serpentine belts are longer and can drive multiple accessories. They feature a single continuous loop, which simplifies routing and reduces weight.

3. Narrow V Belts These belts are designed with a narrower cross-section, which allows for more efficient operation under high loads, making them ideal for high-performance vehicles.

automotive v belt

4. Poly-V Belts Known for their flexibility and strength, poly-V belts feature multiple grooves, allowing them to fit into smaller pulleys and transmit more power in tighter spaces.

Maintenance and Replacement

Regular maintenance of the V belt is essential to ensure the reliable operation of an engine. Common signs that a V belt may need replacing include visible wear, cracks, fraying, or a squeaking noise during operation. Most manufacturers recommend inspecting the V belt at regular service intervals, typically every 30,000 to 60,000 miles, although this can vary based on the vehicle and driving conditions.

When replacing a V belt, it is critical to choose the correct size and type that meets the specifications of the vehicle manufacturer. Incorrect installation can lead to poor performance or damage to engine components. Many vehicle owners opt to have a professional mechanic handle this replacement to ensure precision and avoid potential issues.

Importance of V Belts to Vehicle Performance

The functionality of automotive V belts cannot be overstated. A worn or damaged belt can result in the failure of key engine accessories leading to decreased vehicle performance, overheating, and in some cases, complete engine failure. For instance, if the water pump is not driven effectively due to a poor V belt, the engine may overheat, causing significant damage.

Moreover, in the case of serpentine belts, the failure of a single belt can have a cascading effect on all connected accessories, highlighting the importance of regular inspections and timely replacements.

Conclusion

In conclusion, automotive V belts are vital components that contribute significantly to a vehicle's functionality and performance. Understanding the different types of V belts, their maintenance needs, and the signs of potential failure can empower vehicle owners to take proactive steps in caring for their engines. By ensuring that V belts are in good condition, drivers can enjoy a smoother ride, improved fuel efficiency, and peace of mind knowing they are safeguarding their vehicle's performance.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025