- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jun . 24, 2024 06:13 Back to list

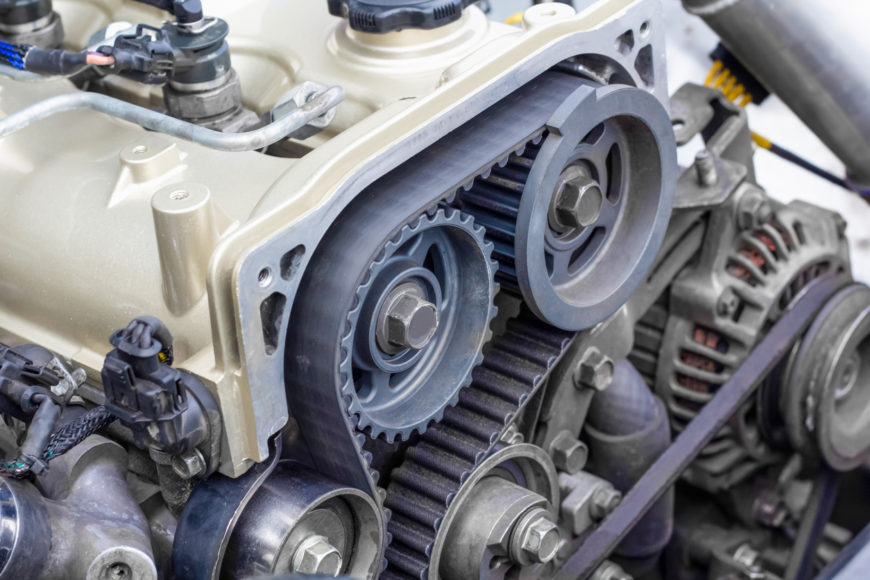

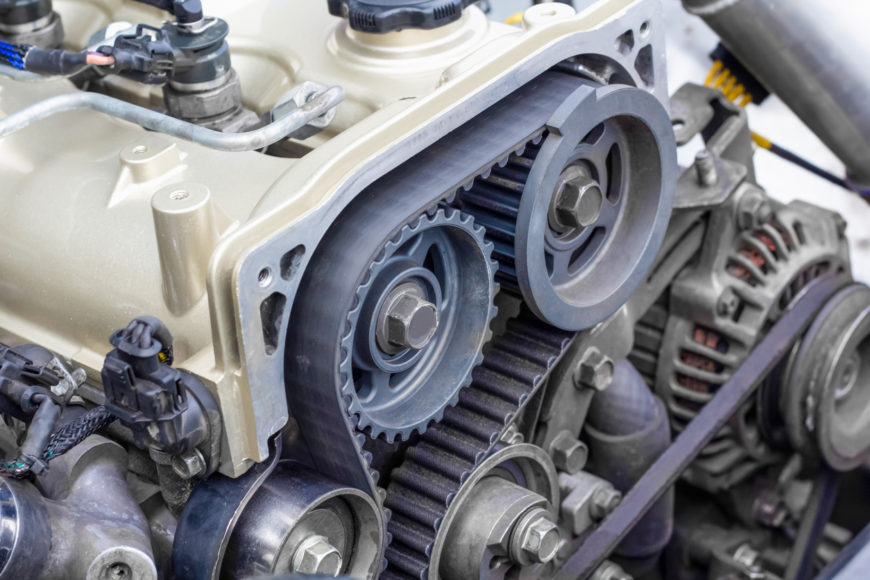

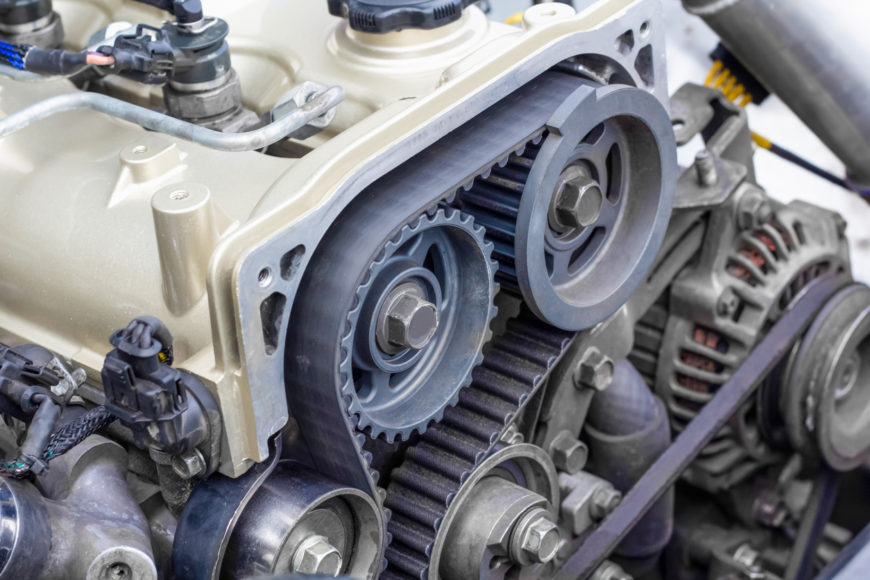

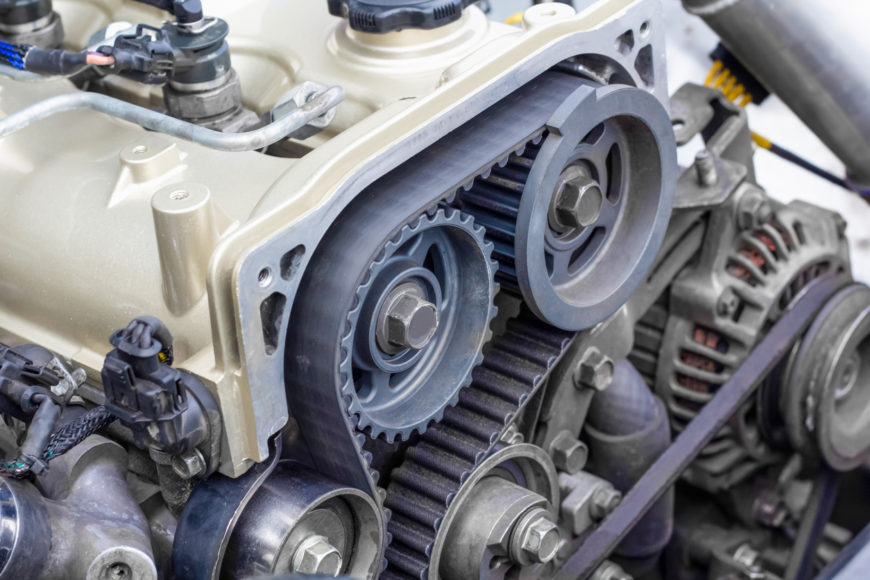

Rubber Belt Manufacturing Equipment

The Pivotal Role of Rubber Belt Making Machines in Modern Industry

In the realm of industrial manufacturing, rubber belts play a crucial role in various applications, from conveying heavy materials in mines and quarries to driving machinery in automotive and food processing industries. The production of these durable and versatile rubber belts is facilitated by specialized machinery, known as rubber belt making machines.

A rubber belt making machine is a sophisticated piece of equipment designed to streamline the process of creating high-quality rubber belts. It combines the art of rubber mixing, calendaring, vulcanizing, and cutting into one seamless operation. The journey from raw rubber to a finished, functional belt is a testament to the ingenuity of modern engineering.

The initial stage involves the preparation of the rubber compound. Raw rubber, often sourced from rubber trees, is mixed with various additives such as fillers, antioxidants, and accelerators to enhance its properties. This process is carried out in a mixer, a key component of the rubber belt making machine, ensuring a homogenous blend.

Once the compound is ready, it passes through a calendaring system. Here, the rubber is flattened into thin sheets, which will form the basis of the belt's structure. The calendaring process allows for precise control over the thickness and texture of the rubber, ensuring consistency in the final product.

The next step is vulcanization, where the rubber sheets are heated and pressed together to create the belt's body. Vulcanization, a chemical process that improves the rubber's strength and resilience, is facilitated by a hydraulic press within the machine Vulcanization, a chemical process that improves the rubber's strength and resilience, is facilitated by a hydraulic press within the machine Vulcanization, a chemical process that improves the rubber's strength and resilience, is facilitated by a hydraulic press within the machine Vulcanization, a chemical process that improves the rubber's strength and resilience, is facilitated by a hydraulic press within the machine

Vulcanization, a chemical process that improves the rubber's strength and resilience, is facilitated by a hydraulic press within the machine Vulcanization, a chemical process that improves the rubber's strength and resilience, is facilitated by a hydraulic press within the machine rubber belts making machine. This step is critical, as it transforms the pliable sheets into a robust, heat-resistant material capable of withstanding the demands of industrial use.

After vulcanization, the rubber belt making machine goes through the precision cutting phase. The belt is cut to the desired width and length, often with intricate patterns or grooves that enhance its grip or performance in specific applications. This process is typically automated, ensuring accuracy and efficiency.

The rubber belt making machine is not just a tool; it is a symbol of the fusion between technology and manufacturing. Its ability to produce belts with precision, speed, and consistency has revolutionized the industry, reducing production costs and increasing productivity. Moreover, with advancements in automation and robotics, these machines continue to evolve, becoming more efficient and adaptable to different belt specifications.

In conclusion, the rubber belt making machine is an integral part of modern industrial infrastructure. Its role in the production of rubber belts is not just mechanical but transformative, shaping the way we manufacture and utilize these essential components in countless industries worldwide. As technology continues to advance, we can expect even more innovative solutions in rubber belt manufacturing, further enhancing the efficiency and durability of these indispensable tools.

rubber belts making machine. This step is critical, as it transforms the pliable sheets into a robust, heat-resistant material capable of withstanding the demands of industrial use.

After vulcanization, the rubber belt making machine goes through the precision cutting phase. The belt is cut to the desired width and length, often with intricate patterns or grooves that enhance its grip or performance in specific applications. This process is typically automated, ensuring accuracy and efficiency.

The rubber belt making machine is not just a tool; it is a symbol of the fusion between technology and manufacturing. Its ability to produce belts with precision, speed, and consistency has revolutionized the industry, reducing production costs and increasing productivity. Moreover, with advancements in automation and robotics, these machines continue to evolve, becoming more efficient and adaptable to different belt specifications.

In conclusion, the rubber belt making machine is an integral part of modern industrial infrastructure. Its role in the production of rubber belts is not just mechanical but transformative, shaping the way we manufacture and utilize these essential components in countless industries worldwide. As technology continues to advance, we can expect even more innovative solutions in rubber belt manufacturing, further enhancing the efficiency and durability of these indispensable tools.

Vulcanization, a chemical process that improves the rubber's strength and resilience, is facilitated by a hydraulic press within the machine Vulcanization, a chemical process that improves the rubber's strength and resilience, is facilitated by a hydraulic press within the machine

Vulcanization, a chemical process that improves the rubber's strength and resilience, is facilitated by a hydraulic press within the machine Vulcanization, a chemical process that improves the rubber's strength and resilience, is facilitated by a hydraulic press within the machine rubber belts making machine. This step is critical, as it transforms the pliable sheets into a robust, heat-resistant material capable of withstanding the demands of industrial use.

After vulcanization, the rubber belt making machine goes through the precision cutting phase. The belt is cut to the desired width and length, often with intricate patterns or grooves that enhance its grip or performance in specific applications. This process is typically automated, ensuring accuracy and efficiency.

The rubber belt making machine is not just a tool; it is a symbol of the fusion between technology and manufacturing. Its ability to produce belts with precision, speed, and consistency has revolutionized the industry, reducing production costs and increasing productivity. Moreover, with advancements in automation and robotics, these machines continue to evolve, becoming more efficient and adaptable to different belt specifications.

In conclusion, the rubber belt making machine is an integral part of modern industrial infrastructure. Its role in the production of rubber belts is not just mechanical but transformative, shaping the way we manufacture and utilize these essential components in countless industries worldwide. As technology continues to advance, we can expect even more innovative solutions in rubber belt manufacturing, further enhancing the efficiency and durability of these indispensable tools.

rubber belts making machine. This step is critical, as it transforms the pliable sheets into a robust, heat-resistant material capable of withstanding the demands of industrial use.

After vulcanization, the rubber belt making machine goes through the precision cutting phase. The belt is cut to the desired width and length, often with intricate patterns or grooves that enhance its grip or performance in specific applications. This process is typically automated, ensuring accuracy and efficiency.

The rubber belt making machine is not just a tool; it is a symbol of the fusion between technology and manufacturing. Its ability to produce belts with precision, speed, and consistency has revolutionized the industry, reducing production costs and increasing productivity. Moreover, with advancements in automation and robotics, these machines continue to evolve, becoming more efficient and adaptable to different belt specifications.

In conclusion, the rubber belt making machine is an integral part of modern industrial infrastructure. Its role in the production of rubber belts is not just mechanical but transformative, shaping the way we manufacture and utilize these essential components in countless industries worldwide. As technology continues to advance, we can expect even more innovative solutions in rubber belt manufacturing, further enhancing the efficiency and durability of these indispensable tools. Share:

Latest news

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025