- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

11月 . 08, 2024 00:20 Back to list

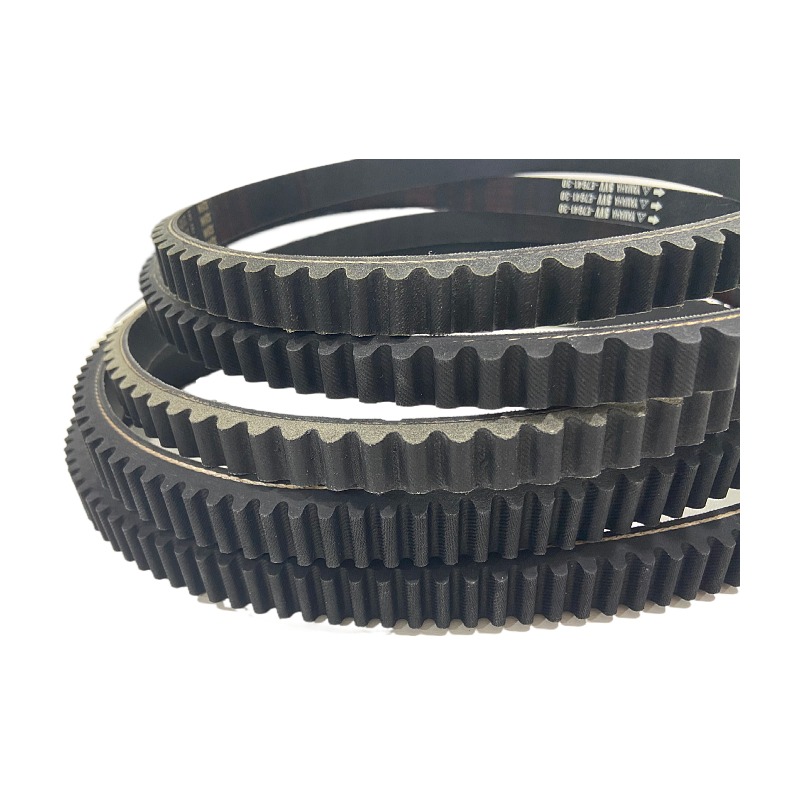

Neoprene Timing Belts for Enhanced Durability and Performance in Mechanical Applications

The Versatility and Utility of Neoprene Timing Belts

In the realm of industrial machinery and automotive engineering, timing belts play a crucial role in maintaining efficiency and precision. Among the various materials used for these components, neoprene has emerged as a favored choice due to its unique properties and advantages. In this article, we will explore the significance of neoprene timing belts, their applications, and the benefits they offer over other materials.

Understanding Neoprene

Neoprene, a synthetic rubber, was developed in the 1930s and has since become a widely used material for various applications. It stands out due to its excellent resistance to oils, chemicals, and weathering, making it an ideal candidate for products exposed to harsh environments. Neoprene exhibits good elasticity and flexibility, which is essential in timing belts that must operate effectively under varied conditions.

The Importance of Timing Belts

Timing belts are critical components in an engine or machinery, serving the purpose of synchronizing the rotation of the crankshaft and camshaft. This synchronization ensures that the engine's valves open and close at the appropriate times in relation to the position of the pistons. In machinery, timing belts are responsible for driving various components such as pulleys and gears. A failure in the timing belt can lead to significant operational failures, potentially causing costly repairs and downtime.

Applications of Neoprene Timing Belts

Neoprene timing belts are utilized in a wide range of applications across different industries. In automotive engineering, they are commonly found in internal combustion engines, where efficient timing is essential for performance. Similarly, in the manufacturing sector, neoprene timing belts are utilized in conveyor systems, robotics, and various machinery that require precise movement and synchronization.

Moreover, neoprene timing belts are also valuable in the printing industry, textile machinery, and even in some consumer appliances

. Their ability to withstand varying temperatures, humidity, and exposure to oils makes them suitable for applications where other materials may break down or lose effectiveness.neoprene timing belt

Advantages of Neoprene Timing Belts

1. Durability Neoprene timing belts are designed to last, offering exceptional wear and tear resistance. This longevity reduces the need for frequent replacements, making them cost-effective in the long term.

2. Flexibility and Stretchability Neoprene is inherently elastic, allowing timing belts made from this material to adapt to various load conditions without losing tension. This flexibility contributes to smoother operation and enhanced performance.

3. Temperature Resistance Neoprene can withstand a broad range of temperatures, making it suitable for high-heat environments common in automotive applications. This temperature resistance ensures that the belts will not fail prematurely, maintaining functionality over extended periods.

4. Resistance to Chemicals The ability of neoprene to resist oils and chemicals is a significant advantage, especially in environments where these substances are prevalent. This property helps prevent degradation over time, ensuring consistent performance.

5. Noise Reduction Neoprene timing belts tend to operate more quietly compared to their metal counterparts, which is a valuable feature in applications where noise levels are a concern.

Conclusion

In summary, neoprene timing belts are an integral part of numerous mechanical systems, delivering reliability and precision in their performance. Their unique properties, including durability, flexibility, and resistance to environmental challenges, make them an ideal choice for a diverse array of applications. As industries continue to advance and innovate, neoprene timing belts will likely remain a cornerstone of effective machinery design, ensuring smooth and efficient operations across varying sectors.

As we look to the future of engineering and manufacturing, it becomes evident that the materials we choose for vital components like timing belts can greatly influence overall performance and reliability. With the proven advantages of neoprene, its role in the continuing evolution of machinery and automotive technology is assured. Thus, choosing neoprene timing belts is not just a decision; it's an investment in quality and efficiency that many industries can benefit from.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025