- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

1月 . 19, 2025 05:00 Back to list

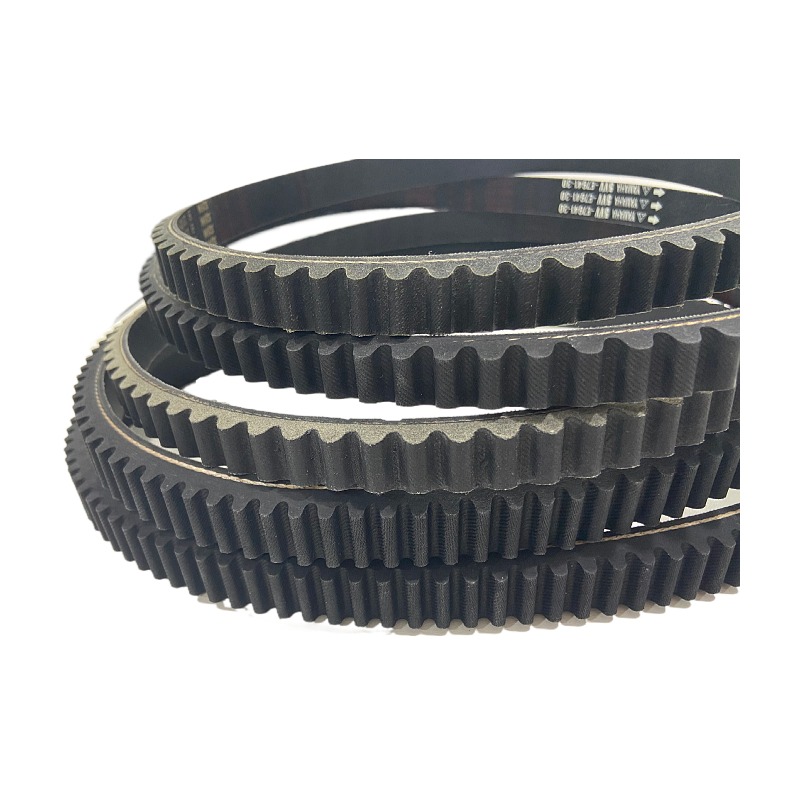

CR A25.8 A36.5 A29 A42.6 Teeth V Rubber Belt

Navigating the intricate world of machinery belts can sometimes be overwhelming. However, understanding their essence, varieties, and critical function can enhance your experience, both practically and technically. Machinery belts are not just another component in the mechanical assembly; rather, they act as the lifeline that keeps optimal business operations running smoothly.

Professional advice is invaluable in this context, and that’s where the expertise of a seasoned engineer can make a world of difference. A professional can assess operational requirements and environmental conditions to recommend the ideal belt, ensuring longevity and efficiency. This comprehensive understanding not only leads to improved performance but also fosters trust among stakeholders who rely on these components for critical operations. Emphasizing the qualities of authoritativeness and trustworthiness, selecting belts from reputable manufacturers is a wise consideration. These manufacturers often adhere to international quality standards, ensuring that every product has undergone rigorous testing. Feature characteristics such as power rating, tensile strength, and the operating temperature range are commonly listed in product manuals from top manufacturers, offering peace of mind in their performance guarantees. One cannot overlook the importance of regular maintenance and care to enhance the longevity of these machinery belts. Routine checks for wear and tear, ensuring correct tension, and adherence to recommended service intervals can prevent premature failures. In cases where machine efficiency diminishes, a swift inspection or recalibration might reveal that the belt has aged beyond its optimal performance span. Engaging maintenance personnel with adequate training in machinery belt care significantly minimizes downtime and extends belt life. In conclusion, the role of machinery belts extends far beyond their physical presence in equipment. Their design intricacies, material composition, and application requirements highlight their importance in ensuring optimal functionality. Whether in automotive, industrial, or even domestic settings, investing time and resources in selecting the right belt, guided by expert advice, can lead to enhanced performance and operational longevity. Thus, the pursuit of a highly efficient, trustworthy machinery belt system remains a relevant testament to engineering prowess and operational excellence.

Professional advice is invaluable in this context, and that’s where the expertise of a seasoned engineer can make a world of difference. A professional can assess operational requirements and environmental conditions to recommend the ideal belt, ensuring longevity and efficiency. This comprehensive understanding not only leads to improved performance but also fosters trust among stakeholders who rely on these components for critical operations. Emphasizing the qualities of authoritativeness and trustworthiness, selecting belts from reputable manufacturers is a wise consideration. These manufacturers often adhere to international quality standards, ensuring that every product has undergone rigorous testing. Feature characteristics such as power rating, tensile strength, and the operating temperature range are commonly listed in product manuals from top manufacturers, offering peace of mind in their performance guarantees. One cannot overlook the importance of regular maintenance and care to enhance the longevity of these machinery belts. Routine checks for wear and tear, ensuring correct tension, and adherence to recommended service intervals can prevent premature failures. In cases where machine efficiency diminishes, a swift inspection or recalibration might reveal that the belt has aged beyond its optimal performance span. Engaging maintenance personnel with adequate training in machinery belt care significantly minimizes downtime and extends belt life. In conclusion, the role of machinery belts extends far beyond their physical presence in equipment. Their design intricacies, material composition, and application requirements highlight their importance in ensuring optimal functionality. Whether in automotive, industrial, or even domestic settings, investing time and resources in selecting the right belt, guided by expert advice, can lead to enhanced performance and operational longevity. Thus, the pursuit of a highly efficient, trustworthy machinery belt system remains a relevant testament to engineering prowess and operational excellence.

Share:

Latest news

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025