- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Ott . 10, 2024 13:41 Back to list

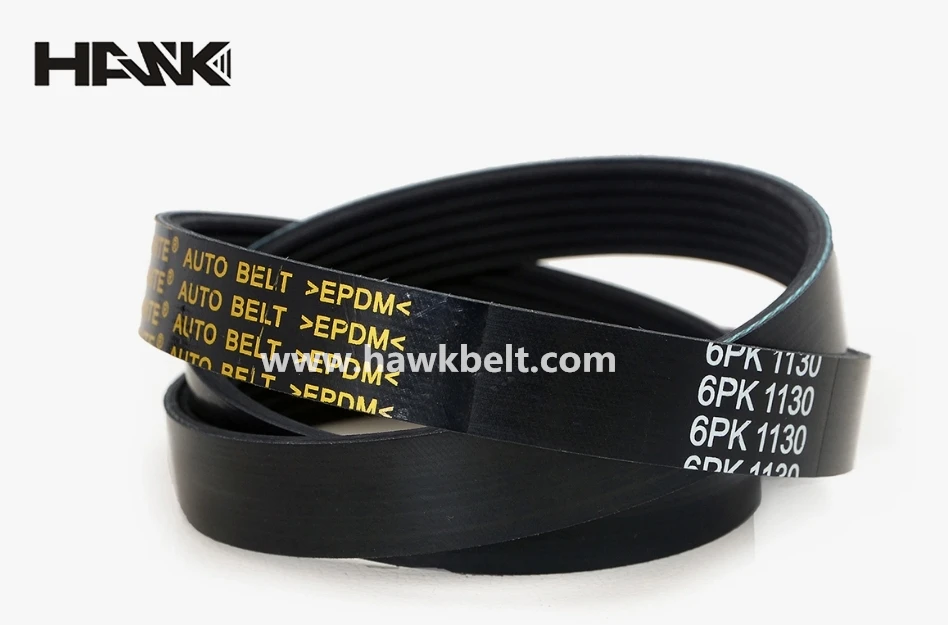

epdm pk belt poly v-belt

The Importance of EPDM Poly V-Belts in Modern Machinery

In the ever-evolving landscape of industrial machinery and automotive engineering, the materials and components utilized in these systems play a crucial role in efficiency, durability, and overall performance. One such essential component is the EPDM poly V-belt, a specialized type of belt that has gained significant popularity due to its outstanding properties and advantages.

Understanding EPDM Poly V-Belts

EPDM stands for Ethylene Propylene Diene Monomer, a type of synthetic rubber known for its excellent resistance to heat, ozone, and weathering. Poly V-belts, characterized by their smaller, continuous V-shaped ribs, are designed to increase surface contact and grip, enabling them to handle high loads with less slippage compared to conventional belts.

The combination of EPDM rubber and the poly V-belt design offers a compelling solution for various applications in automotive and industrial sectors. This hybrid design not only enhances power transmission efficiency but also extends the lifespan of the belt.

Advantages of EPDM Poly V-Belts

1. Temperature Resistance EPDM rubber can withstand a wide range of temperatures without losing its mechanical properties. This makes EPDM poly V-belts ideal for environments where high temperatures are prevalent, such as engine compartments or industrial machinery that generates substantial heat.

2. Ozone and Weather Resistance The ability of EPDM to resist ozone and the effects of weather makes these belts suitable for outdoor applications. This durability ensures that they do not crack or deteriorate when exposed to the elements, significantly reducing maintenance needs.

epdm pk belt poly v-belt

3. Flexibility and Lightweight Design The flexible nature of EPDM poly V-belts allows for easy installation and a wide range of applications. Despite their lightweight structure, they provide substantial strength and stability, resulting in improved efficiency in operations.

4. Reduced Slippage and Noise Level The unique ribbed design of poly V-belts ensures better grip and less slippage, even under high load conditions. Additionally, they operate quietly, which is a significant advantage in environments where noise reduction is crucial.

Applications of EPDM Poly V-Belts

EPDM poly V-belts are utilized across various industries, including automotive, manufacturing, and HVAC (Heating, Ventilation, and Air Conditioning). In automotive applications, they are often found in alternators, power steering systems, and air conditioning compressors. Their ability to handle multiple pulleys and transmit power efficiently makes them an integral part of modern vehicle designs.

In manufacturing, these belts are employed in conveyor systems, pumps, and other machinery that require reliable power transmission. Their durability and resistance to harsh conditions ensure minimal downtime and low maintenance costs.

Conclusion

In summary, EPDM poly V-belts represent a forward-thinking solution for power transmission needs across diverse industries. Their exceptional temperature resistance, flexibility, and durability make them a preferred choice among engineers and technicians who strive for efficiency and reliability. As industries continue to advance and demand more from their components, the role of EPDM poly V-belts will only become more significant, ensuring that machinery operates at optimal levels while minimizing maintenance challenges. Investing in high-quality EPDM poly V-belts is an investment in longevity and performance, making them a critical choice for anyone looking to enhance their systems.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025