- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ágú . 14, 2024 21:22 Back to list

Understanding the Benefits and Applications of V-Ribbed and PK Belts in Mechanical Systems

Understanding V-Ribbed Belts and PK Belts Essential Components for Modern Engines

In the realm of automotive engineering and machinery, the significance of certain components often goes unnoticed by the average consumer. One such component is the v-ribbed belt, also known as a serpentine belt, and its variation, the PK belt. These belts play a crucial role in ensuring the efficient operation of an engine's power transmission system.

What is a V-Ribbed Belt?

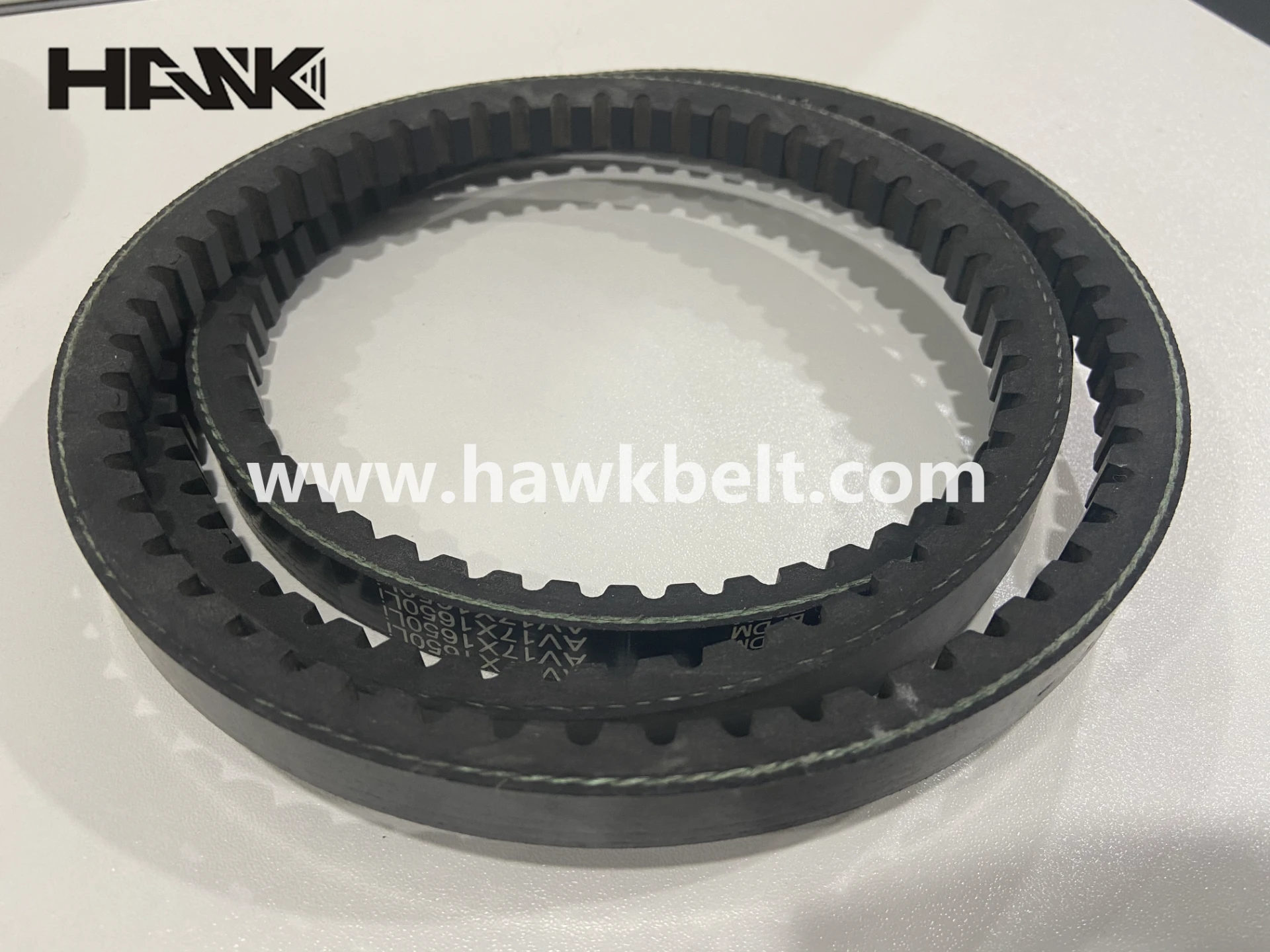

A v-ribbed belt is a type of belt that features a series of ribs or grooves running along its length. This design allows for increased surface area contact between the belt and the pulleys it interacts with. The primary function of a v-ribbed belt is to transfer power from the engine crankshaft to various engine accessories, such as the alternator, power steering pump, water pump, and air conditioning compressor.

One of the key advantages of v-ribbed belts is their flexibility, which enables them to be used in a variety of applications beyond automotive engines. They are found in industrial machines, appliances, and other devices that require power transmission. The ribbed design provides a significant advantage over traditional flat belts, offering better grip and reducing slippage.

The PK Belt A Close Relative

The PK belt is a specific type of v-ribbed belt that follows a standard profile defined by the International Organization for Standardization (ISO). PK belts are generally characterized by their metric dimensions and are widely used in various applications. While they serve a similar purpose to standard v-ribbed belts, PK belts are particularly popular in European vehicles and machinery, adhering to specific design requirements that enable compatibility with standardized pulleys.

v-ribbed belt\/pk belt

The nomenclature for PK belts typically consists of the prefix PK followed by a number indicating the belt's width and rib count. For instance, a PK 5 belt will have a width that allows it to fit snugly into a five-ribbed pulley system. This standardized approach simplifies the selection process for manufacturers, mechanics, and end-users alike.

Why Are V-Ribbed and PK Belts Important?

The importance of v-ribbed belts and PK belts cannot be overstated. They serve as the lifeline of many engine systems, ensuring that various components function in unison. A malfunction in the v-ribbed belt can lead to a cascade of failures, including overheating of the engine, loss of power steering, and failure of electrical components due to a malfunctioning alternator.

Regular maintenance checks are vital to the longevity of these belts. Over time, v-ribbed and PK belts can experience wear and tear due to exposure to heat, oil, and friction. Signs of wear may include cracking, fraying, or glazing, which can compromise the belt's grip on the pulleys. As such, it's advisable for vehicle owners and operators to replace these belts according to the manufacturer’s recommendations or at the first sign of wear.

Conclusion

In summary, v-ribbed belts and PK belts are integral to the efficient functioning of engine systems across various vehicles and machinery. Their design not only enhances power transmission but also contributes to the overall reliability and performance of automotive systems. Understanding their role and maintaining them is crucial for achieving optimal vehicle performance. As technology continues to evolve, so too will the design and application of these important components, ensuring they remain a cornerstone of modern mechanical engineering.

-

Durable Diesel Engine Belt with GPT-4-Turbo AI Tech | Precision Fit

NewsAug.04,2025

-

High-Quality Tensioner Belt Pulley - Durable & Efficient

NewsAug.03,2025

-

Premium Timing Belt Factory | AI-Optimized Solutions

NewsAug.02,2025

-

Premium Custom V Belts Enhanced with GPT-4 Turbo AI

NewsAug.01,2025

-

Car Serpentine Belt: AI-Optimized Performance with GPT-4-Turbo

NewsJul.31,2025

-

Heat Joining Drive Belt | High-Durability Fusion Solution

NewsJul.31,2025