- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

nóv . 08, 2024 04:37 Back to list

Exploring the Benefits and Features of Auto Seatbelts and PK Belts

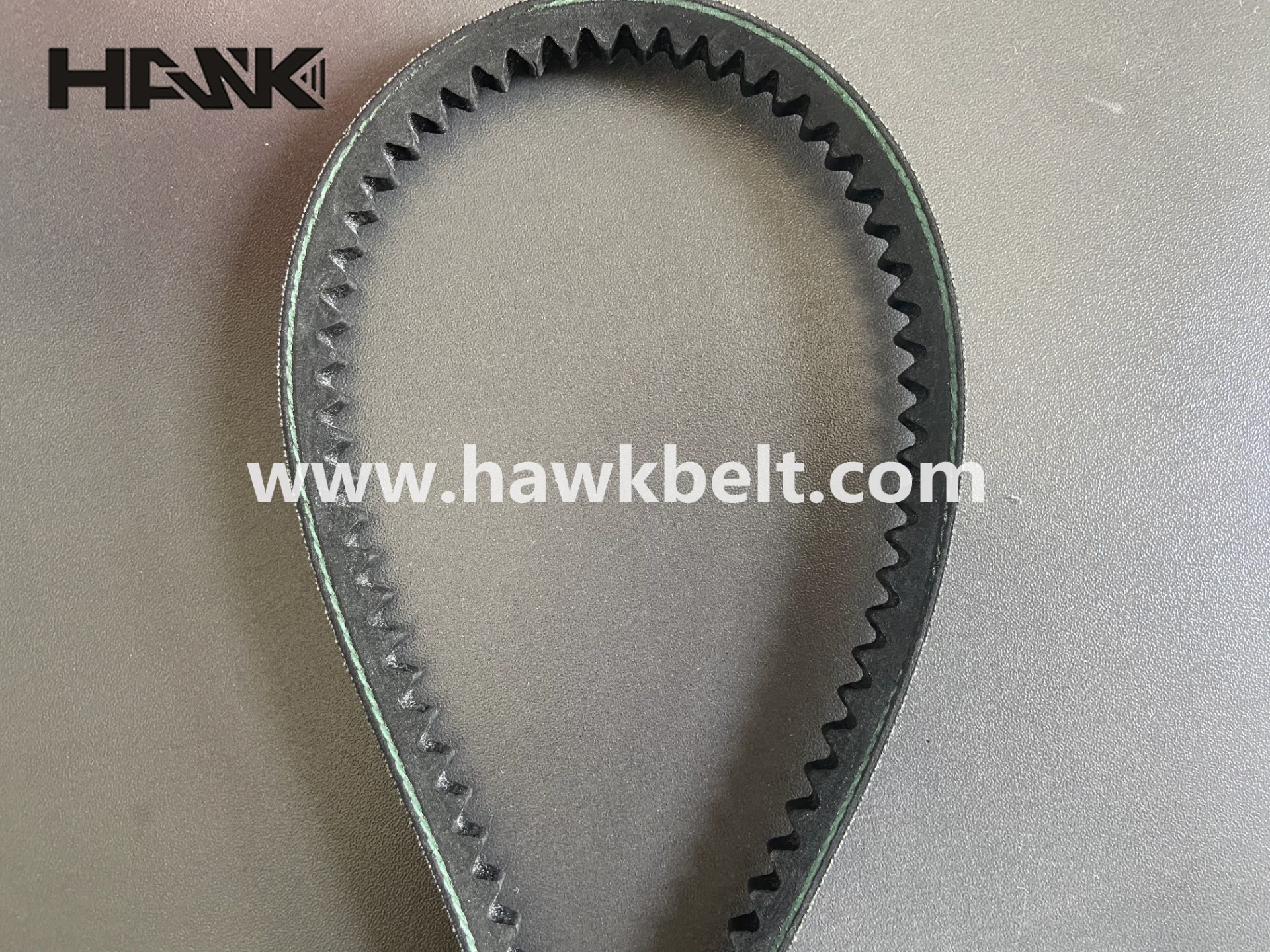

Understanding Auto Belts A Comprehensive Guide to Auto PK Belts

Auto belts, specifically auto PK belts, play a crucial role in the functioning of various machinery and vehicles. Understanding their design, application, and maintenance can help both consumers and professionals optimize the performance of their equipment. This article delves into the intricacies of auto belts, with a focus on auto PK belts, providing a comprehensive guide on their significance in automotive and industrial applications.

What is an Auto PK Belt?

An auto PK belt, popularly referred to as a poly-v belt or serpentine belt, is a type of belt that has multiple grooves, allowing it to maintain a strong grip on pulleys in a wide range of applications. These belts are commonly found in automotive engines where they power essential components such as alternators, power steering pumps, air conditioning compressors, and water pumps. The design of a PK belt provides improved flexibility and surface contact, making them more efficient than traditional V-belts.

Key Features of Auto PK Belts

1. Material Composition Auto PK belts are typically made from high-quality rubber or synthetic materials, which enhance their durability, resistance to wear, and ability to withstand temperature fluctuations. Some PK belts are reinforced with fibers to improve strength and flexibility.

2. Groove Design The unique groove design allows the belt to grip multiple pulleys simultaneously, distributing load and reducing the chance of slippage. This is particularly beneficial in high-performance engines that require precise power transmission.

3. Efficiency Due to their construction, PK belts are designed for optimal performance, reducing energy loss due to friction. This improves fuel efficiency in vehicles and enhances the overall reliability of machinery.

4. Maintenance-Free Unlike traditional belts that require periodic adjustments and replacements, auto PK belts typically boast a longer lifespan and reduced maintenance needs, making them a cost-effective choice in the long run.

Common Applications of Auto PK Belts

Auto PK belts are versatile and find applications across various industries

auto belt\/auto pk belt

- Automotive In vehicles, PK belts are used to drive engine accessories and are engineered to handle the changing loads produced by engine operations.

- Industrial Machinery Many manufacturing processes rely on PK belts to operate conveyors, mixers, and other equipment, ensuring smooth function and high efficiency.

- Agricultural Equipment In agriculture, PK belts are essential for operating machines such as tractors and harvesters, demanding high durability to operate in challenging conditions.

Maintenance of Auto PK Belts

While auto PK belts are designed for longevity, proper maintenance is essential to maximize their lifespan and performance

1. Regular Inspections Visual checks for signs of wear, fraying, or damage can help identify potential issues before they lead to failure. Additionally, inspecting the tension of the belt is crucial.

2. Alignment Check Ensuring that pulleys are aligned correctly helps in preventing uneven wear and enhances performance.

3. Cleaning Keeping the belt clean from dust, oil, and debris can improve grip and overall performance. Use a soft brush or cloth to gently clean the belt surfaces.

4. Replacement If any significant wear or damage is evident, timely replacement is necessary to avoid potential breakdowns or inefficiencies in equipment.

Conclusion

In conclusion, auto PK belts are essential components in both automotive and industrial applications, providing durability, efficiency, and low maintenance. Understanding their features, applications, and maintenance requirements can greatly enhance their utility and performance. As technology advances, the design and materials used in auto PK belts will continue to evolve, further optimizing their roles within various mechanisms. For anyone involved in automotive or machinery operations, knowledge of auto PK belts is key to ensuring smooth and efficient functionality.

-

Upgrade Power Steering Pump Belt for Smooth, Quiet Operation

NewsAug.27,2025

-

Precision Timing Belt & Chain: Engine Performance & Durability

NewsAug.26,2025

-

Precision Lathe Drive Belts: Durable & Reliable Performance

NewsAug.25,2025

-

84.5 Serpentine Belt: Durable & Precision Fit for Your Engine

NewsAug.24,2025

-

Premium Ribbed Drive Belts for Quiet Power Transmission

NewsAug.23,2025

-

High-Performance Vehicle Timing Belt for Engine Precision

NewsAug.22,2025