- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

nov . 10, 2024 09:14 Back to list

V-Belt B76 Specifications and Applications in Industrial Machinery

Understanding V-Belt Sizes A Focus on the B76 Model

In industrial and mechanical applications, the importance of the V-belt cannot be overstated. These belts are crucial for power transmission in various machinery and equipment. Among the different types of V-belts, the B76 model stands out due to its specific dimensions and capabilities. In this article, we will delve into the characteristics, applications, benefits, and maintenance tips related to the B76 V-belt, ensuring a comprehensive understanding of this invaluable component.

What is a V-Belt?

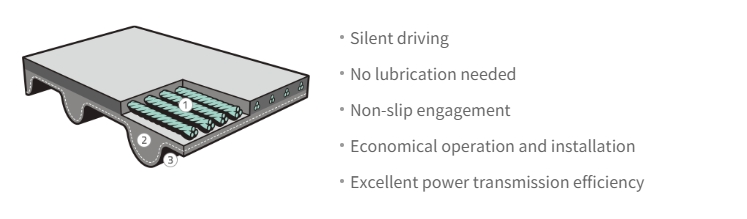

A V-belt is a type of belt used in mechanical systems to transmit power between pulleys. It is designed with a trapezoidal cross-section, allowing it to fit snugly into the grooves of the pulleys it drives. This design maximizes the contact area, improving the belt's grip and minimizing slippage. V-belts are commonly found in various applications, including automotive, industrial machinery, and HVAC systems.

Characteristics of the B76 V-Belt

The B76 model is part of the standard “B” series of V-belts. Its designation indicates specific dimensional characteristics. The B series V-belts typically have a top width of 0.88 inches (22.4 mm) and a height of 0.54 inches (13.7 mm). The '76' signifies the length of the belt in inches, meaning the B76 is approximately 76 inches long. This size makes it suitable for various applications that require a balance between strength and flexibility.

The B76 V-belt is made from durable rubber compounds reinforced with polyester or aramid fibers, providing it with excellent tensile strength and flexibility. This construction is essential for ensuring longevity and reliable performance, particularly in demanding operational environments.

Applications of the B76 V-Belt

The B76 V-belt finds its place in numerous applications across different industries. Some of the most common uses include

1. Agricultural Machinery V-belts are commonly used in tractors and harvesting equipment where reliable power transmission is necessary.

2. HVAC Systems In heating, ventilation, and air conditioning systems, the B76 V-belt plays a crucial role in driving blowers and fans efficiently.

3. Industrial Equipment Many manufacturing processes rely on V-belts to drive conveyors, pumps, and compressors, making the B76 an essential choice for maintaining productivity.

v belt b 76

4. Automotive Applications In certain vehicle models, the B76 may be used in serpentine belt systems, driving multiple accessories from the engine's crankshaft.

Benefits of Using B76 V-Belts

Utilizing the B76 V-belt offers several advantages. Firstly, these belts are designed for high performance, ensuring efficient power transfer with minimal energy loss. Their robust construction allows them to withstand harsh conditions, reduce vibrations, and minimize noise during operation.

Additionally, the B76 V-belt is relatively easy to install and replace, leading to lower maintenance costs. Users can quickly swap out a worn or damaged belt, ensuring that machinery remains operational with minimal downtime.

Maintenance Tips

To ensure the longevity and efficiency of the B76 V-belt, proper maintenance is critical. Here are some essential tips

1. Regular Inspections Routinely check the belt for signs of wear, such as fraying or cracking, and replace it as necessary.

2. Proper Tensioning Ensure that the V-belt is correctly tensioned. Too much slack can lead to slippage, while excessive tension can cause premature wear.

3. Alignment Always check the alignment of the pulleys. Misaligned pulleys can cause uneven wear and reduce the belt's lifespan.

4. Cleanliness Keep the belt and pulleys clean. Dirt and debris can lead to slippage and increased wear.

In conclusion, the B76 V-belt is a reliable and efficient choice for a variety of applications, thanks to its unique design and robust characteristics. By understanding its specifications, benefits, and maintenance requirements, users can optimize their machinery's performance, ensuring a smoother operation in various industrial settings. Whether you're in agriculture, HVAC, or automotive sectors, the B76 V-belt remains a crucial component in your power transmission systems.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025