- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

okt . 22, 2024 13:18 Back to list

flat belts

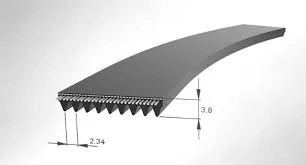

Exploring Flat Belts A Key Component in Mechanical Power Transmission

Flat belts have been a fundamental element in the machinery and engineering sectors for over a century. With their simple design and effective performance, they continue to play a crucial role in various applications, from manufacturing plants to automotive engines. This article explores the characteristics, advantages, and applications of flat belts, highlighting their significance in mechanical power transmission.

A flat belt is a continuous loop of material, usually made from rubber, leather, or fabric, that transmits power between pulleys. The basic design consists of a flexible belt with a flat surface that makes contact with the driving and driven pulleys. Unlike V-belts or round belts, flat belts provide a larger contact area, allowing for higher efficiency in power transfer and reduced wear over time.

One of the primary advantages of flat belts is their adaptability

. They can easily be adjusted to accommodate different lengths and widths, making them suitable for a range of applications. Additionally, they are capable of handling significant loads while maintaining flexibility, enabling smooth operation across various speeds. Flat belts also require minimal maintenance, reducing downtime and costs for businesses.flat belts

In industrial settings, flat belts are commonly used in conveyor systems, where they transport materials over long distances. They can efficiently move products in assembly lines, packaging industries, and food processing facilities. The versatility of flat belts extends to agriculture, where they can drive equipment such as grain elevators and balers, making them invaluable in farming operations.

Furthermore, flat belts are eco-friendly alternatives in power transmission. Their construction materials, such as natural rubber or biodegradable fabrics, contribute to a reduced environmental impact compared to other power transmission systems. This aligns with the growing emphasis on sustainability in modern engineering.

However, flat belts do have limitations, including slippage at high speeds and a lower power transmission capability compared to their V-belt counterparts. Despite these drawbacks, advancements in materials and design have improved their performance, ensuring they remain a viable option in many applications.

In conclusion, flat belts are a crucial component of mechanical power transmission, characterized by their simplicity, efficiency, and versatility. As industries continue to evolve, the role of flat belts in facilitating reliable and sustainable operations is likely to grow, cementing their place in the heart of mechanical engineering. Their ongoing development and integration into modern technologies will ensure they remain relevant in a rapidly advancing world.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025