- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

jún . 12, 2024 11:51 Back to list

Flat rubber conveyor belts

Flat rubber belts, an essential component in various industrial and mechanical applications, play a pivotal role in transmitting power from one point to another with efficiency and reliability. These belts are characterized by their flat surface and flexible nature, which allows them to operate smoothly across a wide range of machinery.

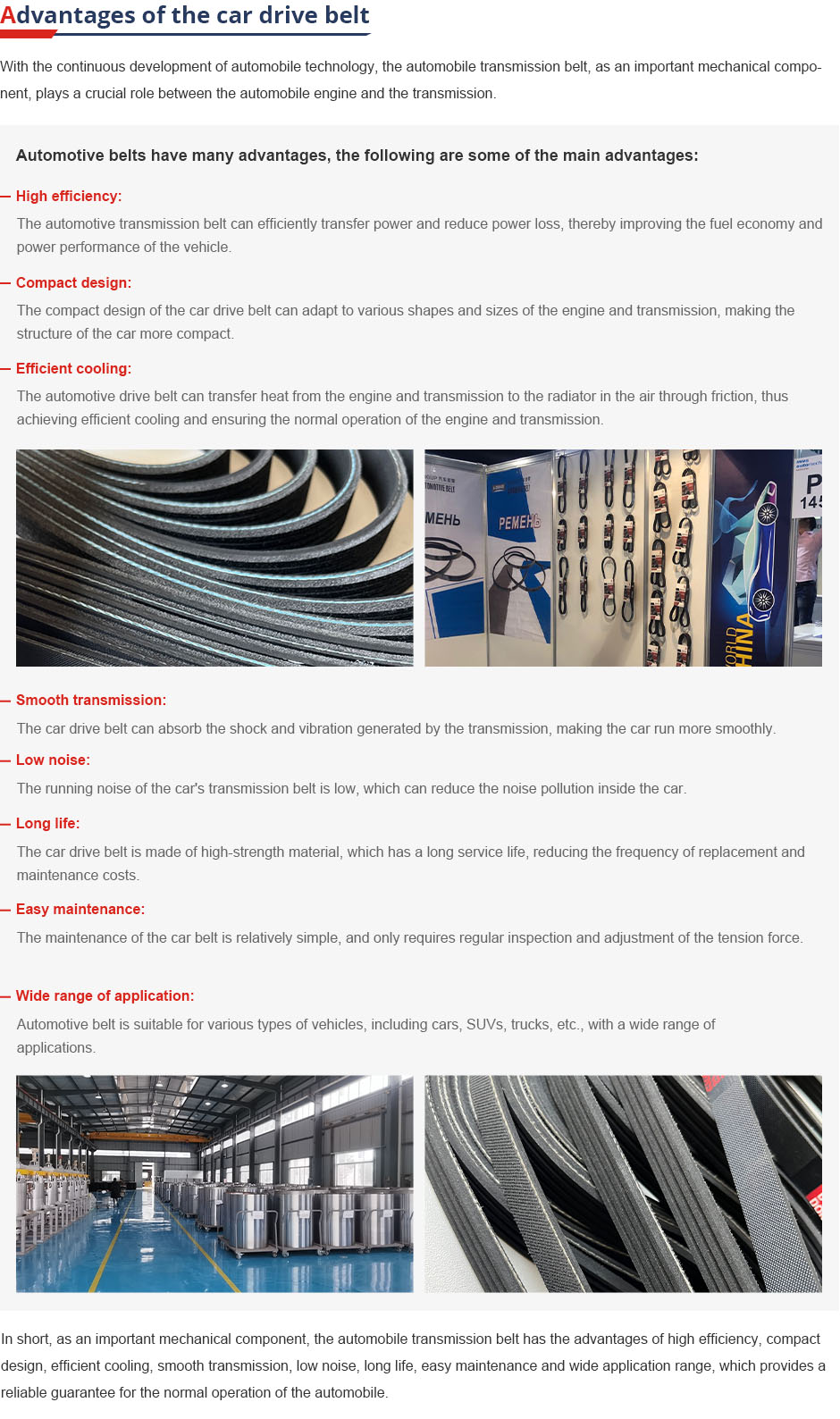

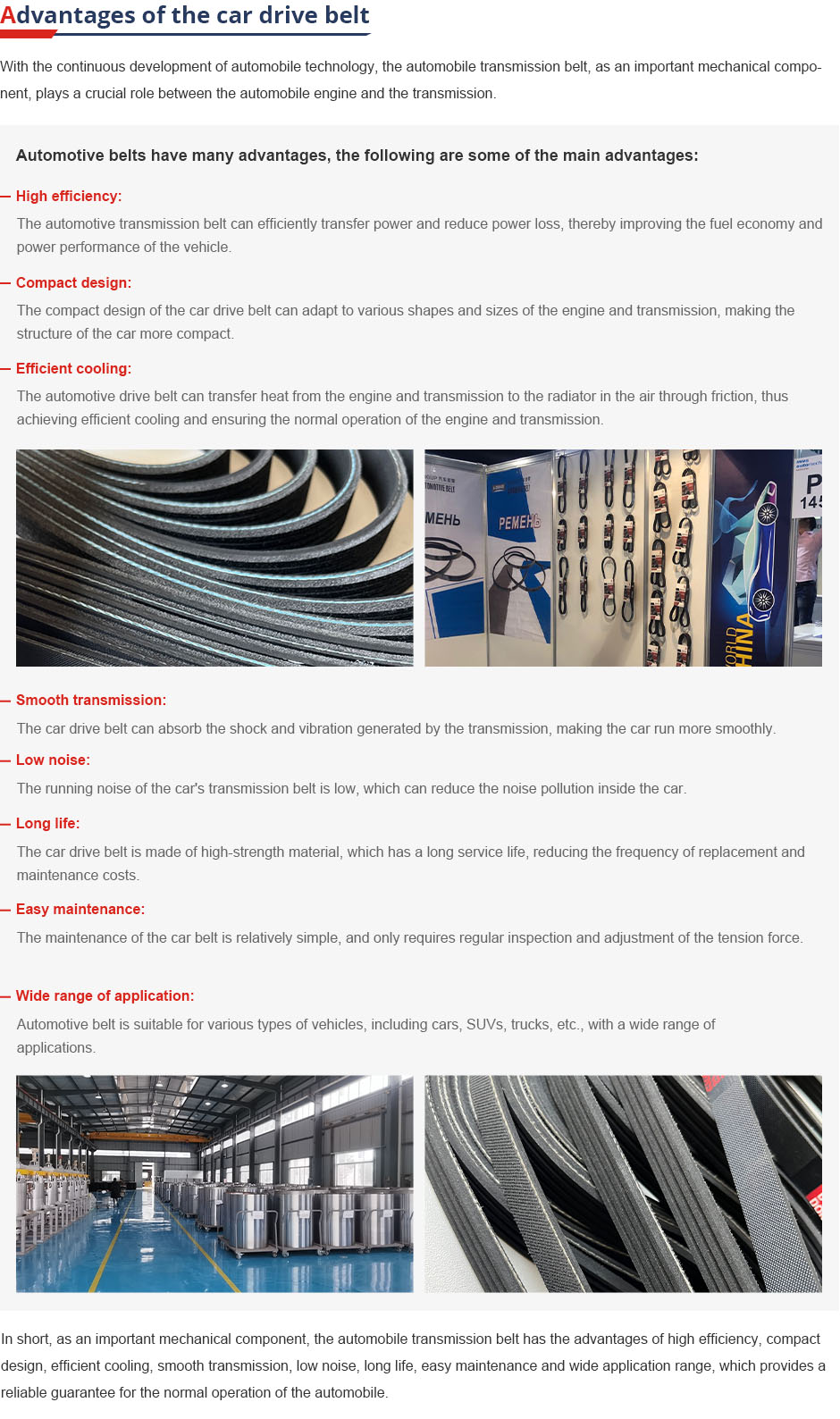

Flat rubber belts are made from a blend of high-quality rubber compounds, often reinforced with fabrics or other materials for added strength and durability. The rubber serves as the primary material, providing the necessary elasticity for the belt to conform to the pulleys while maintaining its integrity under tension. The reinforcement, usually cotton, polyester, or nylon, enhances the belt's tensile strength, enabling it to withstand the stress exerted during operation.

One of the key advantages of flat rubber belts is their versatility. They can be used in numerous applications, from agricultural equipment to manufacturing plants, and even in the automotive industry. In agriculture, they power conveyor systems that transport harvested crops, ensuring a seamless workflow. In manufacturing, they are instrumental in driving assembly line machinery, helping to maintain consistent production speed and precision.

The flat design of these belts offers several benefits. It reduces slippage, enhancing the transmission of power between the belt and pulley. Moreover, this design allows for better contact with the driven surface, leading to improved efficiency Moreover, this design allows for better contact with the driven surface, leading to improved efficiency Moreover, this design allows for better contact with the driven surface, leading to improved efficiency Moreover, this design allows for better contact with the driven surface, leading to improved efficiency

Moreover, this design allows for better contact with the driven surface, leading to improved efficiency Moreover, this design allows for better contact with the driven surface, leading to improved efficiency flat rubber belts. Flat rubber belts also have a low noise level during operation, making them suitable for environments where noise reduction is crucial.

Maintenance of flat rubber belts is relatively straightforward. Regular inspections for signs of wear, such as cracks or fraying, are essential to ensure optimal performance. Prompt replacement when needed can prevent unexpected downtime and potential damage to the machinery.

However, it's important to note that proper installation is vital. A badly aligned or tensioned flat rubber belt can lead to premature failure or reduced efficiency. Operators should follow the manufacturer's guidelines for installation and maintenance to maximize the belt's lifespan.

In conclusion, flat rubber belts, with their robust construction, versatile usage, and efficient power transmission, are indispensable tools in modern industries. Their adaptability, combined with their inherent properties, makes them a reliable choice for a multitude of tasks. As technology continues to evolve, so too will the design and capabilities of flat rubber belts, ensuring their continued relevance in the world of engineering and manufacturing.

flat rubber belts. Flat rubber belts also have a low noise level during operation, making them suitable for environments where noise reduction is crucial.

Maintenance of flat rubber belts is relatively straightforward. Regular inspections for signs of wear, such as cracks or fraying, are essential to ensure optimal performance. Prompt replacement when needed can prevent unexpected downtime and potential damage to the machinery.

However, it's important to note that proper installation is vital. A badly aligned or tensioned flat rubber belt can lead to premature failure or reduced efficiency. Operators should follow the manufacturer's guidelines for installation and maintenance to maximize the belt's lifespan.

In conclusion, flat rubber belts, with their robust construction, versatile usage, and efficient power transmission, are indispensable tools in modern industries. Their adaptability, combined with their inherent properties, makes them a reliable choice for a multitude of tasks. As technology continues to evolve, so too will the design and capabilities of flat rubber belts, ensuring their continued relevance in the world of engineering and manufacturing.

Moreover, this design allows for better contact with the driven surface, leading to improved efficiency Moreover, this design allows for better contact with the driven surface, leading to improved efficiency

Moreover, this design allows for better contact with the driven surface, leading to improved efficiency Moreover, this design allows for better contact with the driven surface, leading to improved efficiency flat rubber belts. Flat rubber belts also have a low noise level during operation, making them suitable for environments where noise reduction is crucial.

Maintenance of flat rubber belts is relatively straightforward. Regular inspections for signs of wear, such as cracks or fraying, are essential to ensure optimal performance. Prompt replacement when needed can prevent unexpected downtime and potential damage to the machinery.

However, it's important to note that proper installation is vital. A badly aligned or tensioned flat rubber belt can lead to premature failure or reduced efficiency. Operators should follow the manufacturer's guidelines for installation and maintenance to maximize the belt's lifespan.

In conclusion, flat rubber belts, with their robust construction, versatile usage, and efficient power transmission, are indispensable tools in modern industries. Their adaptability, combined with their inherent properties, makes them a reliable choice for a multitude of tasks. As technology continues to evolve, so too will the design and capabilities of flat rubber belts, ensuring their continued relevance in the world of engineering and manufacturing.

flat rubber belts. Flat rubber belts also have a low noise level during operation, making them suitable for environments where noise reduction is crucial.

Maintenance of flat rubber belts is relatively straightforward. Regular inspections for signs of wear, such as cracks or fraying, are essential to ensure optimal performance. Prompt replacement when needed can prevent unexpected downtime and potential damage to the machinery.

However, it's important to note that proper installation is vital. A badly aligned or tensioned flat rubber belt can lead to premature failure or reduced efficiency. Operators should follow the manufacturer's guidelines for installation and maintenance to maximize the belt's lifespan.

In conclusion, flat rubber belts, with their robust construction, versatile usage, and efficient power transmission, are indispensable tools in modern industries. Their adaptability, combined with their inherent properties, makes them a reliable choice for a multitude of tasks. As technology continues to evolve, so too will the design and capabilities of flat rubber belts, ensuring their continued relevance in the world of engineering and manufacturing. Share:

Latest news

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025