- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 01, 2024 00:10 Back to list

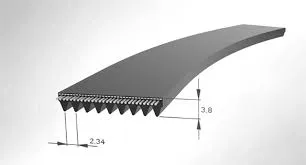

Polyester Flat Belts for Efficient Industrial Applications and Enhanced Durability in Conveying Systems

Exploring the Poly Flat Belt A Versatile Solution for Modern Machinery

In today’s industrial landscape, efficiency and reliability in machinery are paramount. One of the unsung heroes in this realm is the poly flat belt, a simple yet remarkably effective component that plays a critical role in the functioning of various machines. This type of belt, primarily made from durable polymer materials, is designed to provide seamless power transmission while accommodating a diverse range of applications.

Poly flat belts are used in multiple industries, including manufacturing, material handling, and automotive. Their design provides several advantages over traditional rubber belts. For starters, they are less prone to stretching and deformation, ensuring a consistent performance over time. This property is essential in applications where precision and accuracy are imperative, such as in CNC machines or conveyor systems.

One of the key benefits of poly flat belts is their lightweight nature. Unlike heavy-duty rubber belts, poly belts can often reduce the overall weight of the machinery, leading to lower energy consumption. In a world where sustainability is becoming increasingly important, the reduction in energy usage can contribute to a more eco-friendly operational footprint.

Additionally, poly flat belts offer enhanced resistance to wear and tear

. Their ability to withstand various environmental conditions, such as extreme temperatures and exposure to chemicals, makes them ideal for demanding settings. This durability translates to longer service life, reducing the frequency of replacements and maintenance, which can lead to significant cost savings for businesses.poly flat belt

The versatility of poly flat belts extends to their design and sizing options. Manufacturers often provide a wide range of dimensions and profiles, allowing for customization based on specific machine requirements. This adaptability means that poly flat belts can be used effectively in everything from small-scale applications, like printers and small conveyors, to large machinery found in manufacturing and warehouse operations.

Installation and maintenance of poly flat belts are also relatively straightforward. Many users appreciate the ease with which these belts can be installed without the need for specialized tools or extensive training. Regular inspections and maintenance practices can help prolong the life of the belts, ensuring optimal performance throughout their lifespan.

In summary, poly flat belts are an essential component in modern machinery, offering advantages that cannot be overlooked. Their lightweight construction, resistance to wear, customization options, and ease of maintenance make them a superior choice for many applications. As industries continue to evolve and demand more efficient solutions, poly flat belts will undoubtedly play a crucial role in enhancing productivity and performance.

In conclusion, the poly flat belt is more than just a simple conveyor component; it is a vital piece of technology that facilitates smooth operations across various sectors. As manufacturers look for ways to improve efficiency and reduce operational costs, adopting innovations like poly flat belts can lead to significant advancements. The future of industrial machinery lies in integrating reliable, high-performance components like these, which exemplify the importance of quality in engineering design. The poly flat belt stands out as an excellent example of how a well-designed component can positively impact overall productivity and efficiency in industrial applications.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025