- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

pro . 02, 2024 05:32 Back to list

Different Types of Poly V Belts for Various Applications and Uses

Understanding Poly V Belt Types A Comprehensive Guide

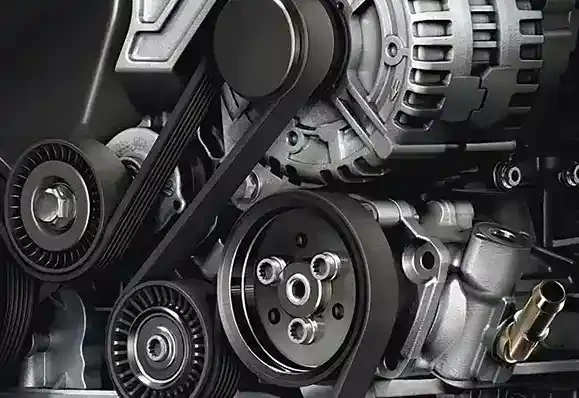

The poly V belt, also known as a poly V or serpentine belt, is a fundamental component in many automotive and industrial applications. It plays a critical role in transferring power between various engine components and auxiliary devices, such as alternators, air conditioning compressors, and power steering pumps. With various types of poly V belts available in the market, it's essential to understand their characteristics and suitable applications to ensure optimal performance and longevity.

What is a Poly V Belt?

A poly V belt is a type of belt characterized by its multiple longitudinal grooves on the inner surface. Unlike traditional V-belts that have a single V-shaped groove, poly V belts feature a flat underside and multiple narrow ribs on the top side. This design allows for better grip and flexibility, enabling the belt to perform efficiently even under high-stress conditions. Its compact form factor means that multiple accessories can be driven by a single belt, reducing the overall weight and complexity of the drive system.

Types of Poly V Belts

When it comes to poly V belts, there are several types, each designed for specific applications and requirements. The most common types include

1. Traditional Poly V Belts These are the standard poly V belts widely used in various vehicles and machinery. They are made from rubber compounds and reinforced with materials like polyester or aramid for added strength. These belts are suitable for applications with moderate power demands and typical operating conditions.

2. High-Performance Poly V Belts Designed for high-stress environments, these belts are built with advanced materials that offer better durability and resistance to wear and tear. They are often used in racing cars or high-performance engines where maximum efficiency and power transfer are crucial.

3. Heat-Resistant Poly V Belts In applications where heat is a significant factor, such as those involving engines that operate at high temperatures, heat-resistant poly V belts are necessary. These belts are formulated with materials that can withstand elevated temperatures without degrading, ensuring consistent performance and longevity.

4. Oil-Resistant Poly V Belts For applications in environments where exposure to oil and other chemicals is common, oil-resistant poly V belts are essential. These belts are treated to resist chemical degradation, making them suitable for industrial machines, agricultural equipment, and other environments where exposure to oil is unavoidable.

poly v belt types

5. Variable Speed Poly V Belts These belts are designed for use in applications that require variable speed operation. They provide enhanced performance in variable frequency drives and other systems where speed adjustments are necessary to optimize performance.

Choosing the Right Poly V Belt

Selecting the appropriate poly V belt for your application involves considering several factors

- Load Requirements Assess the power and torque requirements of the system. High-performance or heat-resistant belts may be necessary for demanding applications.

- Operating Environment Determine the environmental factors that the belt will be exposed to, such as temperature extremes, oil exposure, or chemical agents.

- Compatibility Ensure that the selected belt is compatible with the drive system in terms of size, length, and groove configuration.

- Maintenance Considerations Some poly V belts require regular maintenance to ensure optimal performance, while others are designed to be low-maintenance. Consider your maintenance capabilities when selecting a belt.

Conclusion

Poly V belts are a vital component in many modern machines, from everyday vehicles to specialized industrial equipment. With various types available, understanding their differences and applications is crucial for making the right choice. By considering factors like load requirements, operating environment, and compatibility, you can select a poly V belt that ensures efficient power transfer and enhances the overall longevity of your machinery. Whether you're a vehicle enthusiast, a mechanic, or an industry professional, knowledge about poly V belt types is essential for optimal performance and reliability in your applications.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025