- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

stu . 07, 2024 11:34 Back to list

Understanding the Importance and Functionality of Motor Belts in Machinery

Understanding Motor Belts Key Components in Mechanical Systems

Motor belts are an essential component in many mechanical systems, providing a crucial link between the motor and various driven components. These belts are designed to transfer power efficiently, ensuring that the machinery operates smoothly and reliably. In this article, we will explore the different types of motor belts, their applications, and some considerations for maintenance and selection.

Types of Motor Belts

Motor belts come in various types, each designed for specific applications. The most common types include

1. V-Belts These are one of the most widely used types of belts in industrial applications. The V shape allows the belt to wedge itself into the groove of the pulley, providing a secure grip and reducing slippage. V-belts are versatile and can handle moderate to high power applications, making them ideal for everything from small machinery to large industrial equipment.

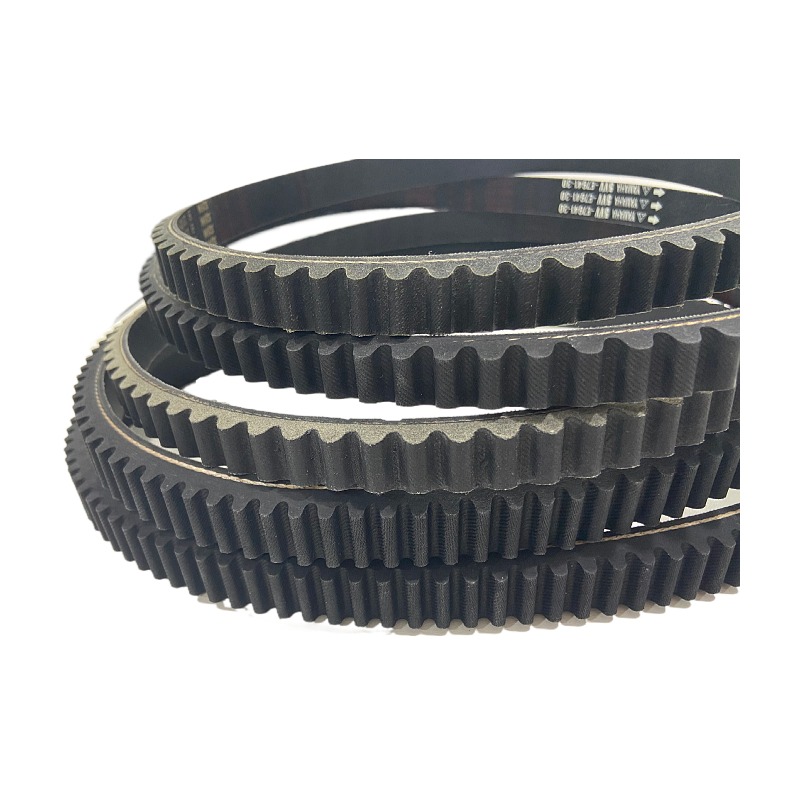

2. Timing Belts Also known as synchronous belts, timing belts have teeth that fit into corresponding grooves on the pulleys. This design ensures that the rotation of the pulleys is synchronized, which is crucial in applications where precise timing is necessary, such as in automotive engines and printing machines.

3. Flat Belts These belts are typically used in applications requiring lower speed and less power. Flat belts are simple in design and can cover longer distances between pulleys. However, they can be less effective in high-power applications due to slippage.

4. Toothed Belts Similar to timing belts, toothed belts have a series of teeth that fit into pulleys. They provide better grip and are used in applications requiring high torque, such as in heavy machinery.

5. Round Belts These are flexible and can easily navigate around small pulleys. Round belts are often used in conveyor systems and light-duty applications where flexibility and ease of installation are crucial.

Applications of Motor Belts

Motor belts are utilized across a wide range of industries. In the automotive sector, timing belts are vital for the engine's operation, ensuring that the crankshaft and camshaft rotate in sync. In manufacturing, V-belts are commonly found in conveyor systems, pumps, and fans, providing the necessary power transmission to keep operations running smoothly. Additionally, you will find motor belts in home appliances like washing machines and lawnmowers, showcasing their versatility and importance in everyday life.

Choosing the Right Motor Belt

motor belts

Selecting the appropriate motor belt for an application involves several considerations

1. Power Requirements The power rating of the machinery will dictate the type of belt that can be used. Higher power applications require more robust belts that can handle increased tension and stress.

2. Speed The speed at which the motor operates is another critical factor. Different belts are rated for specific speed ranges. For example, timing belts are better for high-speed applications due to their reduced slippage.

3. Operating Conditions Environmental factors such as temperature, moisture, and exposure to chemicals can affect belt performance. For instance, if a belt will operate in a high-temperature environment, selecting a belt made from heat-resistant materials is essential.

4. Installation Space The available space for installation may also determine the type of belt you can use. Some applications may benefit from the flat profile of a flat belt, while others may require the tensile strength of a V-belt.

5. Maintenance Consider the maintenance requirements of the belt. Some belts may require regular tension checks and replacements, while others might have a longer lifespan.

Maintaining Motor Belts

Regular maintenance is crucial to extending the life of motor belts. Here are some tips

- Inspect belts for signs of wear, such as cracks, fraying, or glazing. - Ensure proper tension; belts that are too loose can slip, while those that are too tight can cause excessive wear on both the belt and pulleys. - Clean the pulleys and belts to remove debris that can cause slippage. - Replace worn belts promptly to prevent unexpected machine failures.

Conclusion

Motor belts are integral to the functionality of a wide array of machinery and applications. Understanding the different types of belts, their uses, and maintenance requirements can help you choose the right belt for your needs, ensuring efficient and reliable operation in any mechanical system. Whether you are a DIY enthusiast or a professional in the field, recognizing the importance of motor belts will enhance your approach to machinery and equipment management.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025