- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jan . 09, 2025 13:50 Back to list

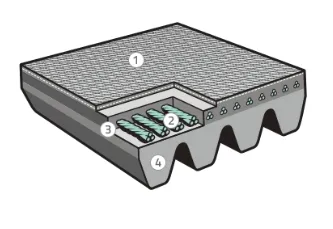

PK Belt 3PK660 For Hyundai 57170-0D001

Truck engine belts are critical components that ensure the seamless operation of a vehicle’s engine system. Understanding their importance, maintenance, and replacement can save you from costly repairs and unexpected breakdowns. This guide provides expert insights into the role of truck engine belts, ensuring your vehicle runs smoothly and efficiently.

Replacement of a truck's engine belts is not just about addressing wear but also about preventing failure. A broken serpentine belt, for instance, can lead to a loss of essential functions, as it powers several components that are vital for engine operation. A snapped timing belt could be catastrophic, potentially causing severe engine damage due to valve interference, leading to bent valves, cylinder head or camshaft damage, and more. When it comes to replacing truck engine belts, always use products from reputable manufacturers known for their durability and reliability. Many brands offer reinforced belts designed to withstand higher stress, making them a prudent choice for heavy-duty trucks subject to demanding conditions. Expertise in selecting the right belt cannot be understated; it should match the specific make and model of your truck to ensure compatibility and optimal performance. Trustworthiness in the information you receive on engine belts is paramount. Always refer to the truck’s manufacturer manual for recommended maintenance schedules and replacement guidelines. Consulting with certified technicians who have a track record of excellence in truck maintenance can also provide peace of mind. Their authoritative knowledge, backed by industry certifications, ensures you’re making informed decisions about your truck’s engine health. In conclusion, maintaining your truck engine belts is a practice rooted in understanding their crucial role and paying attention to wear indicators. Leveraging expert advice and trusting reliable sources and parts will ensure your truck remains operational without unexpected and costly downtimes. So, make engine belt inspection and maintenance a regular part of your vehicle care routine. Your truck will thank you with every mile it runs smoothly.

Replacement of a truck's engine belts is not just about addressing wear but also about preventing failure. A broken serpentine belt, for instance, can lead to a loss of essential functions, as it powers several components that are vital for engine operation. A snapped timing belt could be catastrophic, potentially causing severe engine damage due to valve interference, leading to bent valves, cylinder head or camshaft damage, and more. When it comes to replacing truck engine belts, always use products from reputable manufacturers known for their durability and reliability. Many brands offer reinforced belts designed to withstand higher stress, making them a prudent choice for heavy-duty trucks subject to demanding conditions. Expertise in selecting the right belt cannot be understated; it should match the specific make and model of your truck to ensure compatibility and optimal performance. Trustworthiness in the information you receive on engine belts is paramount. Always refer to the truck’s manufacturer manual for recommended maintenance schedules and replacement guidelines. Consulting with certified technicians who have a track record of excellence in truck maintenance can also provide peace of mind. Their authoritative knowledge, backed by industry certifications, ensures you’re making informed decisions about your truck’s engine health. In conclusion, maintaining your truck engine belts is a practice rooted in understanding their crucial role and paying attention to wear indicators. Leveraging expert advice and trusting reliable sources and parts will ensure your truck remains operational without unexpected and costly downtimes. So, make engine belt inspection and maintenance a regular part of your vehicle care routine. Your truck will thank you with every mile it runs smoothly.

Share:

Latest news

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025