- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 26, 2024 14:09 Back to list

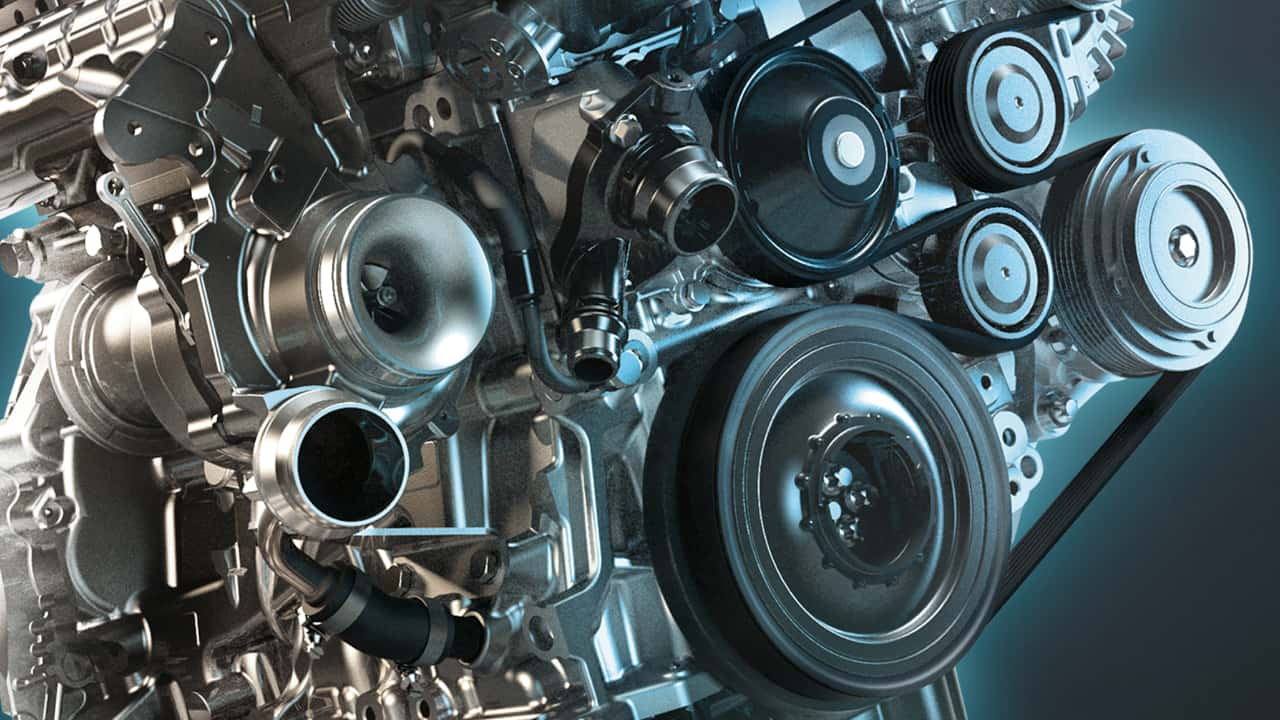

Exploring the Benefits and Applications of Rubber V Belts in Modern Machinery

The Versatility and Applications of Rubber V Belts

Rubber V belts, often simply referred to as V belts, are essential components in a wide variety of mechanical systems. Their unique design and material composition provide an effective means of power transmission in numerous applications, making them a critical element in various industries, including automotive, industrial machinery, and consumer products. This article will explore the characteristics, advantages, and applications of rubber V belts, highlighting their importance in modern engineering.

Design and Material Characteristics

Rubber V belts are characterized by their trapezoidal cross-section, enabling them to fit snugly into corresponding drive pulleys. This design allows for a larger surface area for contact, resulting in increased traction between the belt and the pulley. Typically made from rubber or rubber blends, these belts are reinforced with materials like polyester or fiberglass to enhance strength and durability. The flexibility of rubber enables the belt to bend around pulleys and align easily with other components, making it an effective solution for power transmission.

Benefits of Using Rubber V Belts

The Versatility and Applications of Rubber V Belts

Another significant benefit of rubber V belts is their resistance to wear and heat. The rubber compounds used in manufacturing provide excellent durability, allowing the belts to perform reliably even under extreme conditions. This resistance to environmental factors, such as moisture and oil, further enhances their longevity, reducing the need for frequent replacements and maintenance.

rubber v belts

Applications in Various Industries

Rubber V belts are widely used across multiple sectors, showcasing their versatility. In the automotive industry, they play a pivotal role in the operation of vehicles by connecting the engine to various accessories, such as alternators, water pumps, and air conditioning compressors. A well-functioning V belt ensures that these components operate in harmony, contributing to the vehicle's overall performance and efficiency.

In industrial applications, rubber V belts are commonly employed in conveyor systems, where they facilitate the movement of goods and materials. Their strength and grip allow for the efficient transportation of heavy loads within factories, warehouses, and construction sites. Furthermore, rubber V belts are integral to the operation of machinery such as fans, pumps, and compressors, where they help maintain consistent performance levels.

Rubber V belts are also found in household appliances, such as washing machines and lawnmowers. In these applications, the belts contribute to the seamless operation of various mechanical parts, ensuring that appliances function effectively and reliably.

Maintenance and Replacement

While rubber V belts are durable, regular maintenance is essential to ensure their longevity. Users should routinely check for signs of wear, such as fraying, cracking, or glazing, which can indicate that a belt needs replacement. Proper tensioning is also critical; belts that are too loose can slip, while overly tight belts can cause premature wear on both the belt and the pulleys.

In conclusion, rubber V belts are vital components in a myriad of mechanical systems, providing an efficient and reliable means of power transmission. Their robust design and adaptability make them indispensable across various applications, from automotive to industrial machinery. Understanding the characteristics, benefits, and maintenance of rubber V belts can help users maximize their performance and lifespan, ultimately contributing to the efficiency and reliability of the systems they serve.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025