- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Dec . 05, 2024 14:40 Back to list

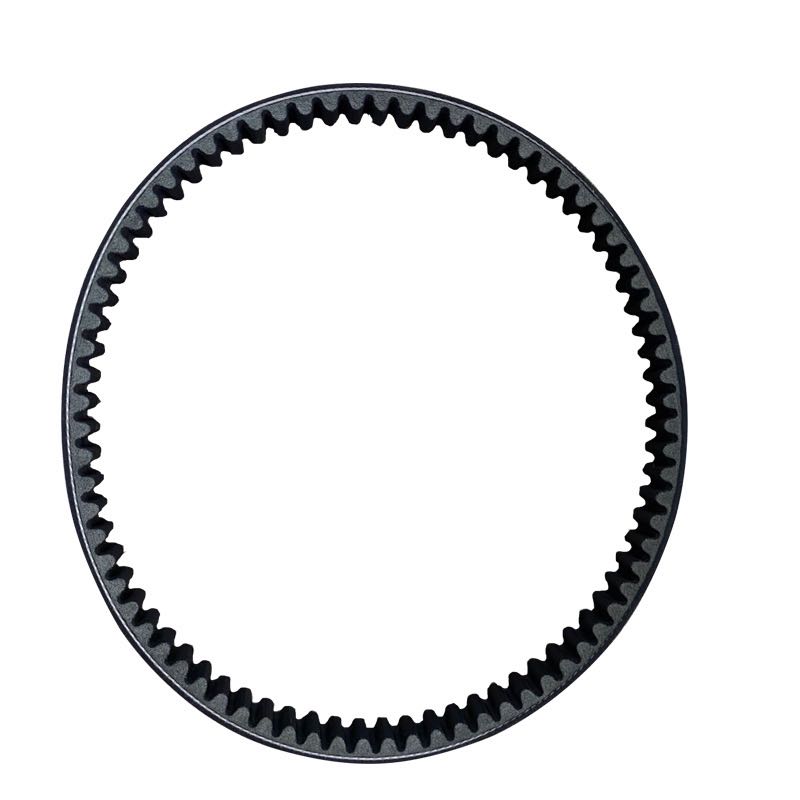

Comparing Flat Belts and V Belts in Power Transmission Applications

Understanding Flat Belts and V-Belts Their Significance in Mechanical Systems

In the realm of mechanical engineering, belts play a crucial role in the transmission of power and motion. Among the various types of belts, flat belts and V-belts are two of the most commonly used. Each type has its unique structure, advantages, applications, and limitations, making them suitable for different tasks in the intricate machinery of modern technology.

Flat Belts

Flat belts are straightforward, flexible belts that have a rectangular cross-section and are typically made from materials such as rubber, fabric, or leather. They operate on the principle of friction, transferring motion and power from one pulley to another. The design of flat belts allows for considerable length and flexibility, making them ideal for transmitting power across longer distances.

Advantages of Flat Belts

1. Simplicity Flat belts consist of a simple construction that doesn’t include grooves or ribs, allowing for easy manufacturing and maintenance. 2. Adapts to Various Pulleys Due to their flat structure, these belts can be used on various sizes and shapes of pulleys, enhancing versatility in application. 3. Less Heat Generation With minimal slippage and overheating, flat belts tend to operate cooler than some other belt types, increasing their lifespan and efficiency.

Applications of Flat Belts

Flat belts are commonly used in various industrial applications, particularly where power transmission over long distances is required. They are frequently found in

- Conveyor systems in manufacturing plants, where they carry products between different stages of production. - Agricultural machinery, aiding in the operation of equipment like threshers and harvesters. - Textile machinery, helping drive spinning and weaving machines.

Despite their numerous advantages, flat belts have certain limitations. Their reliance on friction can sometimes result in slippage, particularly under high loads or with significant misalignment. This slippage can lead to inefficiencies and increased wear on the belts and pulleys.

flat belt and v belt

V-Belts

In contrast to flat belts, V-belts have a trapezoidal cross-section, resembling the letter V. This shape allows V-belts to fit snugly into corresponding grooves on pulleys. The design promotes a more efficient transmission of power due to increased surface contact and improved frictional grip.

Advantages of V-Belts

1. Higher Power Transmission The wedge shape of V-belts increases the contact area, allowing them to handle greater loads and transmit more power than flat belts over short distances. 2. Reduced Slippage V-belts are less prone to slippage, making them suitable for high-speed applications where reliability is crucial. 3. Compact Design They require less space than flat belts and can be used in tighter configurations, allowing for more compact machinery designs.

Applications of V-Belts

V-belts are prevalent in many mechanical systems due to their effectiveness and reliability. Common applications include

- Automotive engines, where they drive accessories such as alternators, air conditioning compressors, and water pumps. - HVAC systems, ensuring ventilation and air conditioning equipment operates efficiently. - Industrial machines, powering everything from conveyors to mixers and crushers.

While V-belts are celebrated for their performance, they also come with their challenges. They can be sensitive to misalignment and length variations, which can lead to premature wear. Moreover, V-belts typically require tension adjustments and periodic replacement as they elongate over time.

Conclusion

Both flat belts and V-belts play significant roles in the transmission of power within various machinery and systems. Understanding their characteristics, advantages, and limitations is crucial for engineers and technicians seeking to optimize performance and durability in mechanical designs. The choice between flat belts and V-belts ultimately depends on specific application needs, load requirements, and space constraints. By making informed decisions about belt selection, industries can enhance operational efficiency and prolong the lifespan of their equipment.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025