- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

अगस्त . 12, 2024 11:02 Back to list

Understanding the Benefits and Applications of Poly Rib Belts in Modern Machinery Systems

Understanding Poly Rib Belts An Overview of Their Function and Importance

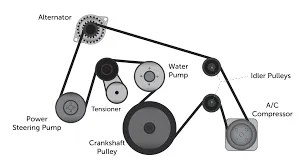

In the modern machinery and automotive industry, efficient power transmission is critical for optimal performance. One of the essential components that facilitate this process is the poly rib belt, also known as a serpentine belt. These belts are designed to transfer power from the engine's crankshaft to various components, including the alternator, water pump, air conditioning compressor, and power steering pump. This article explores the construction, advantages, applications, and maintenance of poly rib belts.

Construction and Design

A poly rib belt is typically made from high-quality rubber or elastomer materials, which enhances its durability and flexibility. What sets poly rib belts apart from traditional V-belts is their ribbed surface, which increases the surface area for grip without sacrificing flexibility. This rib configuration allows the belt to efficiently transmit torque at various angles and positions, reducing slippage and wear. Additionally, poly rib belts often incorporate fiber reinforcement, which enhances strength and resistance to tearing.

Advantages of Poly Rib Belts

One of the most significant advantages of poly rib belts is their ability to drive multiple accessories simultaneously. Unlike traditional systems that often require separate belts for each component, a single poly rib belt can achieve the same results, simplifying the design and reducing the number of components in an engine system. This not only leads to weight savings but also minimizes the risk of belt failure since fewer belts mean fewer potential points of failure.

Moreover, poly rib belts are designed to operate quietly and smoothly, reducing noise in comparison to older belt technologies

. Their efficient design leads to improved fuel economy, as engines do not have to work as hard to run auxiliary components.Applications

poly rib belt

Poly rib belts are used across a wide range of industries, primarily in automotive applications. Most modern vehicles utilize poly rib belts due to their efficiency and reliability. Besides automobiles, these belts find applications in agricultural equipment, industrial machines, and even household appliances, such as washing machines and dryers.

In automotive use, poly rib belts are responsible for powering critical systems. For example, they ensure that the alternator generates electricity, the water pump circulates coolant, and the air conditioning compressor provides climate control. The failure of a poly rib belt can lead to engine overheating, loss of power steering, or a malfunctioning electrical system, emphasizing their critical role.

Maintenance and Replacement

Maintaining poly rib belts involves routine inspections to check for signs of wear such as cracks, fraying, or glazing. It is advisable to consult the vehicle's service manual for recommended inspection intervals. Most manufacturers recommend replacing poly rib belts every 60,000 to 100,000 miles, although this can vary based on driving conditions and usage.

Failure to replace a worn or damaged belt can lead to more severe engine issues, resulting in costly repairs. Signs of a failing belt can include squeaking noises when starting the engine, power steering issues, or flickering dashboard lights indicating electrical problems.

Conclusion

In summary, poly rib belts are vital components in today's automotive and industrial machinery, ensuring efficient power transmission across multiple systems. Their advanced design offers numerous advantages over traditional belts, including the ability to drive multiple components, reduced noise, and improved fuel efficiency. Regular maintenance and timely replacement of these belts are crucial for maintaining optimal engine performance and preventing potential failures. Understanding the importance of poly rib belts can help vehicle owners and operators make informed decisions regarding their maintenance and care, ensuring their machinery runs smoothly and efficiently.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025