- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

सितम्बर . 23, 2024 19:17 Back to list

A Comprehensive Guide to Various Types of Poly V Belts and Their Applications

Understanding Poly V-Belt Types

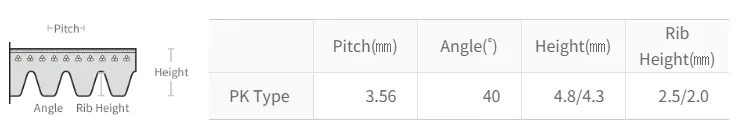

Poly V-belts, also known as serpentine belts, are an essential component in many mechanical systems, providing power transmission in a compact and efficient manner. They are distinct from traditional V-belts due to their unique design featuring multiple thin ridges or grooves along their length. This design allows them to operate smoothly on smaller pulleys and enables them to handle high levels of torque, making them ideal for various automotive and industrial applications.

Understanding Poly V-Belt Types

Another type is the narrow poly V-belt, which is designed for applications where space is constrained. With a width smaller than traditional belts, they can fit into tighter spaces without sacrificing performance. Narrow poly V-belts are often found in small engines, such as those in lawnmowers or recreational vehicles, where compact design is crucial.

poly v belt types

For heavy-duty applications, heavy-duty poly V-belts are available. These belts are constructed to withstand higher loads and harsher conditions, making them suitable for industrial machinery and commercial vehicles. They often feature additional reinforcement to resist wear and tear, extending their lifespan even in demanding environments.

Additionally, there are poly V-belts designed with specific material properties, such as oil resistance or high-temperature resistance. Oil-resistant belts are crucial in environments where exposure to oils and fuels is common, while high-temperature belts are necessary in applications such as automotive engines where extreme heat can be a factor.

When selecting a poly V-belt, it's essential to consider factors such as the application requirements, load conditions, and environmental factors. Proper installation and maintenance are equally important to ensure optimal performance and longevity of the belt. Regular inspections should be conducted to check for signs of wear, such as cracking or fraying, which can indicate the need for replacement.

In summary, poly V-belts provide a versatile and efficient solution for power transmission in various applications. Their diverse types cater to a wide range of needs, from standard belts for everyday use to specialized belts for demanding conditions. Understanding the different types of poly V-belts can help in selecting the right one for your specific application, ensuring reliability and performance in your mechanical systems.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025