- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

दिसम्बर . 10, 2024 03:26 Back to list

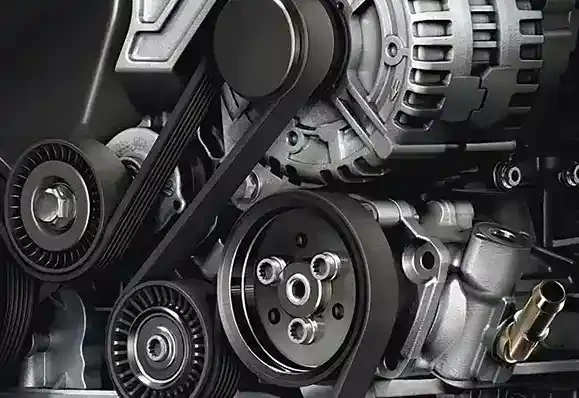

Understanding the Mechanics and Applications of Belt Drive Systems in Engineering

Understanding Belt Drives Applications and Advantages

Belt drives are an essential component in many mechanical systems, offering a reliable means of transmitting power from one component to another. They are commonly used in various industries, including manufacturing, automotive, and agriculture, to transfer motion and power between rotating shafts. This article will delve into the workings of belt drives, their applications, advantages, and potential drawbacks.

What is a Belt Drive?

A belt drive system consists of a few key components the drive pulley (or sheave), the driven pulley, and the belt itself. The belt, typically made of rubber, fabric, or a combination of materials, loops around the drive and driven pulleys. When the drive pulley turns, it causes the belt to move, which in turn rotates the driven pulley, thereby transferring power from one to the other.

Types of Belts

There are several types of belts used in belt drive systems. The most common include

1. V-Belts These have a trapezoidal cross-section, offering better grip and the ability to transmit more power without slipping. They are widely used in automotive engines and industrial machinery.

2. Flat Belts These have a rectangular cross-section and are typically used in lower power applications. They are often employed in conveyor systems and small mechanical setups.

3. Timing Belts Equipped with teeth that mesh with corresponding grooves on the pulleys, timing belts ensure precise synchronization between components, making them indispensable in applications like automotive engines and 3D printers.

Applications

belt drive

Belt drives find applications in a variety of sectors. In manufacturing, they are used to power machines like lathes, saws, and conveyors. In agriculture, belt drives can be found in equipment such as tractors and harvesters, effectively transferring power from the engine to other components. Automotive systems also heavily rely on belt drives, particularly in handling auxiliary systems like the alternator, water pump, and air conditioning compressor.

Advantages of Belt Drives

One of the primary advantages of belt drives is their ability to absorb shock loads, which helps protect other mechanical components. Additionally, they can operate over a significant distance, allowing flexibility in the layout of machinery. Belt drives also tend to be quieter and more efficient than gear systems, with less vibration and lower maintenance requirements.

Another significant benefit is the ease of installation and replacement. Compared to gear systems, which can be complex and require precision alignment, belt drives are generally simpler to install and adjust, making them user-friendly for various applications.

Potential Drawbacks

Despite their many advantages, belt drives do have some limitations. One of the main concerns is that they can slip under high load conditions, particularly if the belt is worn or not properly tensioned. Regular maintenance is essential to ensure optimal performance. Additionally, belts can experience wear and tear, which may necessitate replacement over time.

Environmental conditions can also impact the effectiveness of belt drives. High temperatures or exposure to chemicals can lead to degradation of the belt material, resulting in potential failures if not monitored closely.

Conclusion

In summary, belt drives play an integral role in many mechanical systems across a wide range of industries. Their ability to efficiently transfer power, coupled with their shock-absorbing qualities and ease of maintenance, makes them a preferred choice for many applications. However, like any mechanical system, they require regular attention to ensure longevity and efficiency. Understanding the various types of belts, their applications, and the balance of their advantages and drawbacks is crucial for effectively utilizing belt drive systems in modern machinery.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025