- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

דצמ . 16, 2024 14:02 Back to list

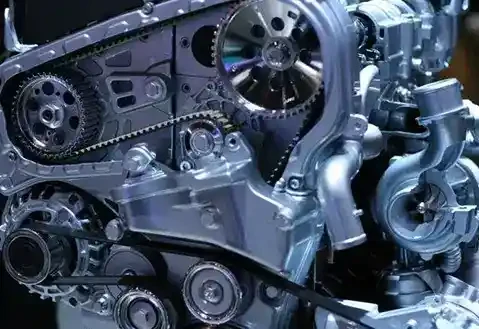

poly v belt drive

Understanding Poly V Belt Drives

Poly V belt drives are an innovative solution in mechanical power transmission systems, designed to enhance efficiency and performance in a variety of applications. Known for their compact design and superior load-carrying capacity, Poly V belts have gained popularity in both industrial and automotive sectors. This article delves into the characteristics, advantages, applications, and maintenance of Poly V belt drives.

Characteristics of Poly V Belts

Poly V belts, also referred to as serpentine belts or multi-V belts, feature a unique design that incorporates multiple V-shaped grooves along their length. This multi-groove structure allows them to operate more efficiently than traditional V-belts. Poly V belts are typically made from high-quality materials such as rubber, polyurethane, or composite materials, which enhance their durability and performance.

One of the key characteristics of Poly V belts is their ability to transmit high power in a compact space. Their small cross-section allows for tighter spacings between pulleys, enabling manufacturers to design more compact machinery without compromising performance. Additionally, the belt's flat side provides a larger contact area with the pulley, which reduces slippage and enhances energy transmission.

Advantages of Poly V Belt Drives

The use of Poly V belts comes with a plethora of advantages

1. High Efficiency Poly V belts provide greater surface contact with pulleys, resulting in improved energy transfer and reduced energy losses due to slippage. This leads to more efficient power transmission compared to traditional drive systems.

2. Space-Saving Design Due to their smaller size and design, Poly V belts require less space than traditional V-belt systems. This compactness allows for a more optimized design in machinery, making it ideal for applications where space is at a premium.

3. Reduced Weight Poly V belt drives are lighter than standard v-belt systems. This reduction in weight can positively impact the overall weight of the machinery, leading to lower energy consumption and improved operational efficiency.

4. Quiet Operation The design and materials used in Poly V belts promote quieter operation compared to other belt types. This makes them suitable for applications where noise reduction is a priority, such as in automotive or household appliances.

poly v belt drive

5. Versatility Poly V belts are used in a variety of applications, ranging from automotive engines to industrial machinery. Their adaptability makes them suitable for various industries, including HVAC, agriculture, and manufacturing.

Applications of Poly V Belt Drives

Poly V belt drives have extensive applications across multiple industries

- Automotive Industry One of the most common applications for Poly V belts is in automotive engines. They are used to drive various accessories such as alternators, power steering pumps, and air conditioning compressors. The compact design and efficiency of these belts maximize the performance of the engine.

- Industrial Machinery In manufacturing and production lines, Poly V belts effectively transmit power between motors and driven machinery. Their ability to handle significant loads within limited spaces makes them ideal for conveyor systems, pumps, and other industrial equipment.

- Household Appliances Many household appliances, such as washing machines and vacuum cleaners, utilize Poly V belts due to their quiet operation and reliability. These belts help in driving motors that power these appliances, contributing to their overall efficiency.

Maintenance of Poly V Belt Drives

To ensure the longevity and optimal performance of Poly V belt drives, regular maintenance is essential. Here are some key maintenance tips

- Regular Inspections Periodically check the tension of the belt and inspect for signs of wear, such as cracks or fraying. - Correct Alignment Ensure that pulleys are correctly aligned to prevent uneven wear on the belt. - Replacement Replace the belts as per the manufacturer's recommended guidelines to avoid unexpected failures.

Conclusion

Poly V belt drives are a highly effective solution for modern power transmission needs, offering efficiency, compactness, and versatility. Their numerous advantages make them a preferred choice in a vast array of applications, from automotive to industrial settings. With proper maintenance, Poly V belts can provide reliable performance, thereby enhancing the overall efficiency of the equipment they serve. As technology continues to evolve, the importance of such advanced mechanical components will only grow, shaping the future of power transmission systems further.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025