...

2025-08-14 20:27

2852

...

2025-08-14 20:15

1845

...

2025-08-14 20:14

1531

...

2025-08-14 20:11

2530

...

2025-08-14 20:10

1373

...

2025-08-14 19:52

2646

...

2025-08-14 19:46

97

...

2025-08-14 19:40

2178

...

2025-08-14 19:31

783

...

2025-08-14 18:55

1703

- Next comes the application of a primer, which serves as a bonding agent between the old surface and the new layer of fiberglass

In recent decades, carbon aerogels have been widely explored by using graphitic carbons and soft carbons, which show advantages in superelasticity. These elastic aerogels usually have delicate microstructures with good fatigue resistance but ultralow strength. Hard carbons show great advantages in mechanical strength and structural stability due to the sp3 C-induced turbostratic “house-of-cards” structure. However, the stiffness and fragility clearly get in the way of achieving superelasticity with hard carbons. Up to now, it is still a challenge to fabricate superelastic hard carbon-based aerogels.

- The group winding machine, or GWM, is designed to handle multiple spools of yarn simultaneously. It does this by grouping these spools together on a single spindle, which then winds the yarn onto a single bobbin. This process is not only faster but also more accurate than traditional winding methods, resulting in fewer defects and improved yarn quality.

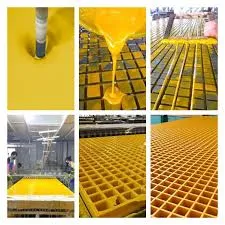

- The installation of pultruded fiberglass grating is straightforward, often involving clipping the panels into place or using drilled holes for bolting. Maintenance is minimal as the material does not require painting or special treatments to preserve its function or appearance over time.

The anchoring drilling bits cut through the soil and rock, creating a hole that will be used to anchor the structure The anchoring drilling bits cut through the soil and rock, creating a hole that will be used to anchor the structure

The anchoring drilling bits cut through the soil and rock, creating a hole that will be used to anchor the structure The anchoring drilling bits cut through the soil and rock, creating a hole that will be used to anchor the structure

For example, dome-shaped buttons are ideal for hard and abrasive rock formations, while conical buttons are better suited for softer formations For example, dome-shaped buttons are ideal for hard and abrasive rock formations, while conical buttons are better suited for softer formations

For example, dome-shaped buttons are ideal for hard and abrasive rock formations, while conical buttons are better suited for softer formations For example, dome-shaped buttons are ideal for hard and abrasive rock formations, while conical buttons are better suited for softer formations