A compound feed heavy duty sewing machine is equipped with a unique feeding mechanism that combines different feed types needle feed, walking foot, and presser foot. This combination allows the machine to pull the fabric evenly from both the top and bottom, ensuring smooth stitching even on thick or multi-layered materials. This capability makes it ideal for sewing heavy fabrics such as leather, denim, canvas, and various synthetic materials.

Heavy-duty denim thread is typically made from polyester or cotton, providing a strong and resilient structure that can withstand the strain of heavy fabrics. Its thickness, which is significantly greater than standard sewing threads, allows it to create strong seams that can endure wear and tear. Furthermore, heavy-duty denim thread is often pre-waxed or treated to enhance its grip and prevent fraying, ensuring that the seams remain intact even after extensive use.

Larger Working Surface

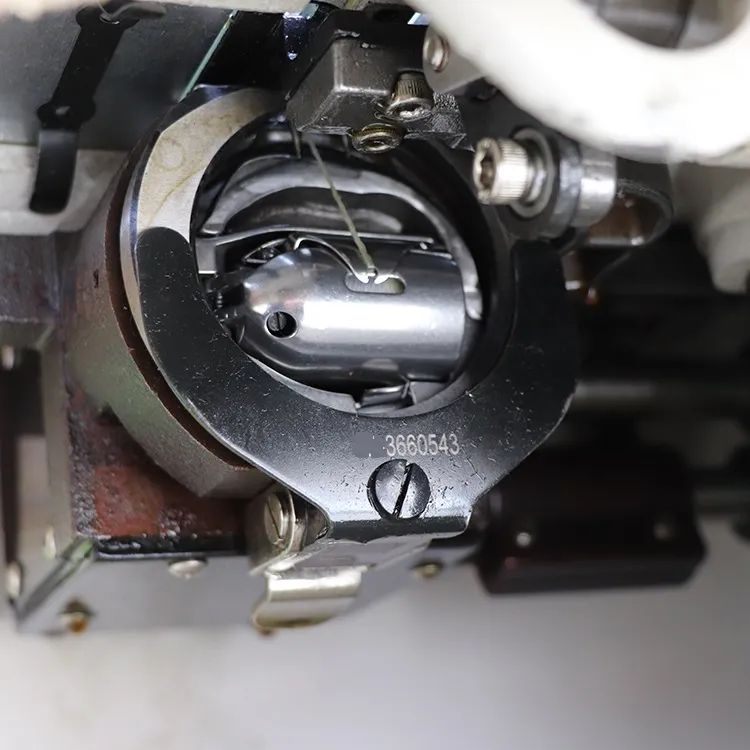

The design of the bobbin shuttle hook has evolved significantly over the years. Early sewing machines used a simple curved hook, which, while functional, lacked the efficiency and speed of modern designs. The introduction of the rotary hook mechanism revolutionized the sewing industry. This design allowed for faster sewing speeds, better stitch quality, and reduced the noise associated with older machines. The intricacies of modern bobbin shuttle hooks are a testament to years of innovation and engineering, culminating in a component that is both robust and efficient.

bobbin shuttle hook

Advantages of Hand Sewing Machines

2. Durability and Speed Commercial models are built for heavy-duty use, making them ideal for busy sewing environments. They are equipped with powerful motors that can sew at high speeds, thereby increasing productivity. This feature is particularly beneficial for businesses that require quick turnaround times.

commercial zig zag sewing machine

Maintenance is another consideration when selecting a sewing machine for both fabric and leather. Leather can leave oils and residues on the machine, necessitating regular cleaning and proper oiling. Heavy-duty machines generally require less frequent maintenance due to their robust construction but keeping an eye on parts like the needle and feed dogs will prolong the life of your machine.

The versatility of the floating foot sewing machine makes it an invaluable tool for a wide range of sewing projects. From crafting clothing to creating home décor items like cushions and curtains, this machine handles it all with ease. It's invaluable for quilters who need to sew together multiple layers without compromising the integrity of their work. Additionally, the floating foot is also effective for free-motion embroidery, allowing seamstresses to express their artistic flair.

Another idea is to sew outdoor gear such as camping chairs or hammocks. Heavy canvas can withstand the elements, making it suitable for outdoor activities. When sewn correctly, these items can offer comfort and durability, lasting through many seasons of adventure.

5. Maintenance Capabilities Given the intensive use of these machines, easy maintenance and access to replacement parts are vital for minimizing downtime and ensuring smooth production workflows.

A commercial zig zag sewing machine is designed to produce a variety of stitch types, particularly the zig zag stitch, which is a fundamental technique in sewing. The zig zag stitch allows for several applications, including finishing raw edges, creating decorative patterns, and applying elastic. Unlike standard sewing machines, which may be limited to straight stitches, commercial zig zag machines typically feature more advanced options, making them suitable for both heavy fabrics and delicate materials.

One of the standout features of these machines is their ability to accommodate different button sizes effortlessly. Most models come equipped with a specialized attachment or sensor that determines the size of the button placed in the machine. Once the size is detected, the machine automatically adjusts its settings to sew a buttonhole that perfectly fits the button, ensuring a secure and polished finish every time.

The Benefits and Features of Multi Needle Quilting Machines

industrial sewing machine needles for leather. The size of the needle refers to the diameter of the needle shaft, with larger numbers indicating thicker needles. For sewing leather, it is recommended to use needles with sizes ranging from 14 to 18, as these sizes are strong enough to penetrate through the material without causing damage.

Creative Freedom and Artistic Expression

What is an Industrial Long Arm Sewing Machine?

The single needle stitch, often hailed as one of the fundamental techniques in sewing and embroidery, epitomizes precision and craftsmanship. Rooted in centuries of tradition, this method has transcended time, finding relevance in both contemporary fashion and classic artisanal workmanship. While sewing might seem like a simple task to some, the single needle stitch embodies a level of detail and finesse that can elevate any fabric creation.