These oil seals are created from a low-temperature tolerant compound. Benefits include:

Polyacrylate

Better heat, oil and chemical resistance than NBR

It is recommended for use in oil which contains load bearing additives such as EP gear oils

• More compact thanks to the thin plate (uses a high-strength steel plate)

Silicone Oil Seals - Designed to absorb lubricants in order to lessen wear and friction, silicone rotary shafts also offer high thermal resistance and a large temperature range. But, they do not handle abrasions well or interact with oxidized oils.

In choosing the right oil seal type for your application, it is essential to assess factors such as speed, temperature range, pressure levels, chemical compatibility, shaft material, and installation space limitations. By considering these factors carefully, you can ensure that you select an oil seal that will provide optimal performance and longevity in your specific application.

Its sealing edge comes in full contact with the shaft surface in order to provide excellent sealing performance.

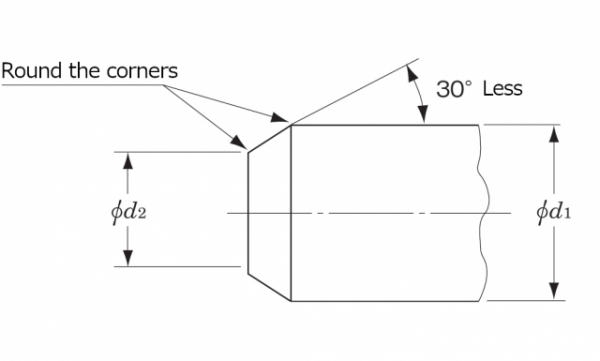

(See Figure 3.)

car spark plug replacement. Be cautious not to damage the threads or the surrounding parts. Inspect the removed plugs for signs of wear, corrosion, or cracks, which can provide valuable insights into your engine's health.

car spark plug replacement. Be cautious not to damage the threads or the surrounding parts. Inspect the removed plugs for signs of wear, corrosion, or cracks, which can provide valuable insights into your engine's health.