- Fiberglass chemical tanks have emerged as an indispensable component in various industrial processes due to their exceptional resistance to harsh chemicals and robust construction. These tanks, also known as FRP (Fiber Reinforced Plastic) tanks, are fabricated using a combination of glass fibers and resin, offering a unique blend of durability and adaptability.

insert rock bits. Engineers use advanced software to map out the drilling path, ensuring the bits are aligned optimally for maximum effectiveness. This not only enhances drilling speed but also reduces wear and tear, extending the lifespan of the bits.

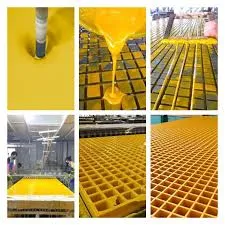

insert rock bits. Engineers use advanced software to map out the drilling path, ensuring the bits are aligned optimally for maximum effectiveness. This not only enhances drilling speed but also reduces wear and tear, extending the lifespan of the bits.This type of grating is commonly used for offshore installations or on ships. It can be safely submerged in water and will not become damaged or corroded by salt water.

What Are The Performance Advantages Of Fiberglass Grating

fiberglass reinforced pipe. The durability of FRP pipes also helps to reduce the risk of leaks and failures, providing a reliable and long-lasting solution for critical infrastructure.

Molded fiberglass grating is available in various thicknesses, mesh patterns and dimensional sizes. Square mesh patterns enable the cutting of the panels efficiently, to accommodate a variety of floor layouts, while reducing the waste to minimal. Molded fiberglass mesh in rectangular shape is mostly used for trench covers in many industrial designs and is also a preferred grating option for walkways. The optional grit-top walking surfaces of fiberglass grating provide skid-resistance for the safety of the workers as well. The design of fiberglass grating is to ensure its reliability, in the most challenging conditions.